Viscosity reduction type water reducing agent

A water-reducing agent and viscosity-reducing technology, which is applied in the field of water-reducing agents, can solve the problems of insufficient functional strength and complex functional raw materials of polycarboxylate water-reducing agents, achieve good water-reducing performance, simple synthesis method, and improve compressive strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

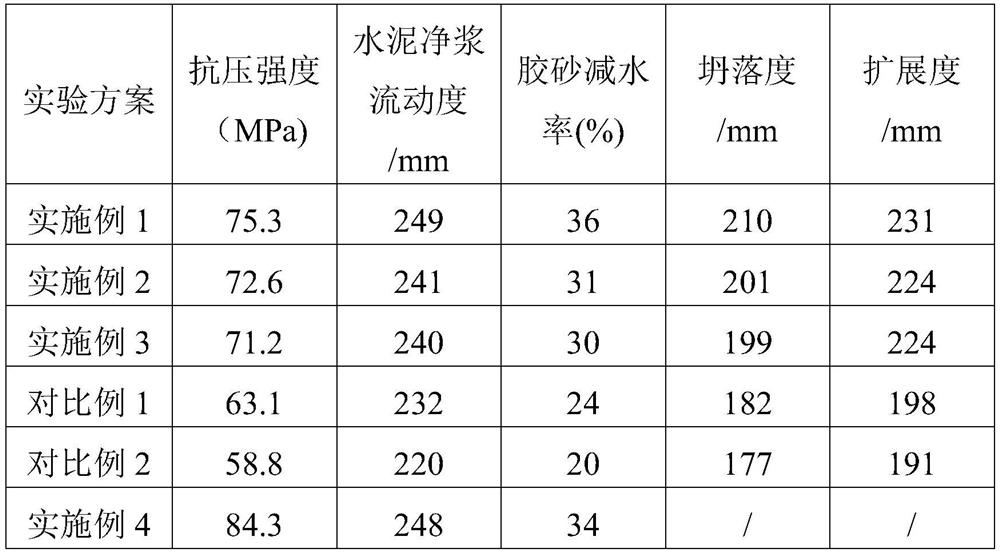

Examples

Embodiment 1

[0043] A preparation method of a viscosity-reducing water reducer, comprising the following steps:

[0044] Step 1. Add 8 parts of acrylic acid and 2 parts of 2-methallyl polyoxyethylene ether into the container, stir evenly, and configure a mixed solution;

[0045] Step 2. Add 0.12 parts of thioglycolic acid, 1 part of citric acid and 1 part of hydrogen peroxide to the mixed solution, stir at room temperature 25°C, and the stirring speed is 300r / min; then use a water bath to heat the reaction, and at 75°C, the reaction 3h, finally using 30wt% sodium hydroxide aqueous solution to adjust the pH to 7 to obtain a modified acrylic acid solution;

[0046] Step 3. Add 40 parts of prenol polyoxyethylene ether and 60 parts of water into the four-necked bottle, raise the temperature to 60°C, and prepare a prenol polyoxyethylene ether solution after the solvent is completely dissolved; Add 2 parts of 10wt% ammonium persulfate aqueous solution, 5 parts of modified acrylic acid solution ...

Embodiment 2

[0051] A preparation method of a viscosity-reducing water reducer, comprising the following steps:

[0052] It is basically the same as Example 1, the only difference is:

[0053] The preparation method of described modified N,N-dimethyl (methacryloyloxyethyl) aminopropanesulfonic acid inner salt is as follows, and the parts are parts by weight:

[0054] S1. Add 25 parts of N,N-dimethyl (methacryloyloxyethyl) aminopropanesulfonic acid inner salt and 50 parts of methanol into a sealed container, stir evenly, and prepare a mixed solution;

[0055] S2. Add 3 parts of tetraethyl orthosilicate dropwise to the mixed solution at a rate of 0.8mL / min; then add 1 part of potassium tert-butoxide, vacuumize the reaction vessel, heat the water bath to 60°C, and The reaction was carried out with a stirring speed of 300r / min and a stirring time of 24h; the obtained precipitate was filtered; and then dried in vacuum at 25°C to obtain modified N,N-dimethyl (methacryloyloxyethyl ) inner salt ...

Embodiment 3

[0057] A preparation method of a viscosity-reducing water reducer, comprising the following steps:

[0058] It is basically the same as Example 1, the only difference is:

[0059] The preparation method of described modified N,N-dimethyl (methacryloyloxyethyl) aminopropanesulfonic acid inner salt is as follows, and the parts are parts by weight:

[0060] S1. Add 25 parts of N,N-dimethyl (methacryloyloxyethyl) aminopropanesulfonic acid inner salt and 50 parts of methanol into a sealed container, stir evenly, and prepare a mixed solution;

[0061] S2. Add 7 parts of 3-hydroxyl-1-methyltetrahydropyrrole dropwise to the mixed solution at a rate of 0.8 mL / min; then add 1 part of potassium tert-butoxide, vacuumize the reaction vessel, and heat the water bath to 60 ℃, reacted under stirring conditions, the stirring speed was 300r / min, and the stirring time was 24h; the obtained precipitate was filtered; and then dried in vacuum at 25°C to obtain the modified N,N-dimethyl (formazan ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Upper mouth diameter | aaaaa | aaaaa |

| Lower mouth diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com