Olmesartan medoxomil amlodipine compound tablet and preparation method thereof

A technology for olmesartan medoxomil and compound tablets, which is applied in the field of medicine, can solve problems such as complex preparation process, inconsistent release curve, poor material fluidity, etc., and achieve the effect of simple preparation method, qualified dissolution curve and improved product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044]Embodiment 1, prepare the compound tablet of olmesartan medoxomil and amlodipine besylate

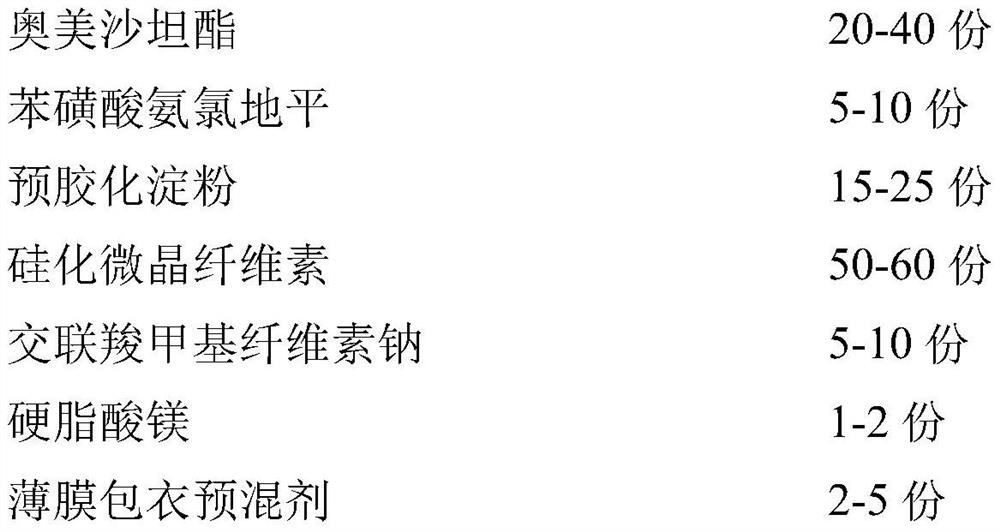

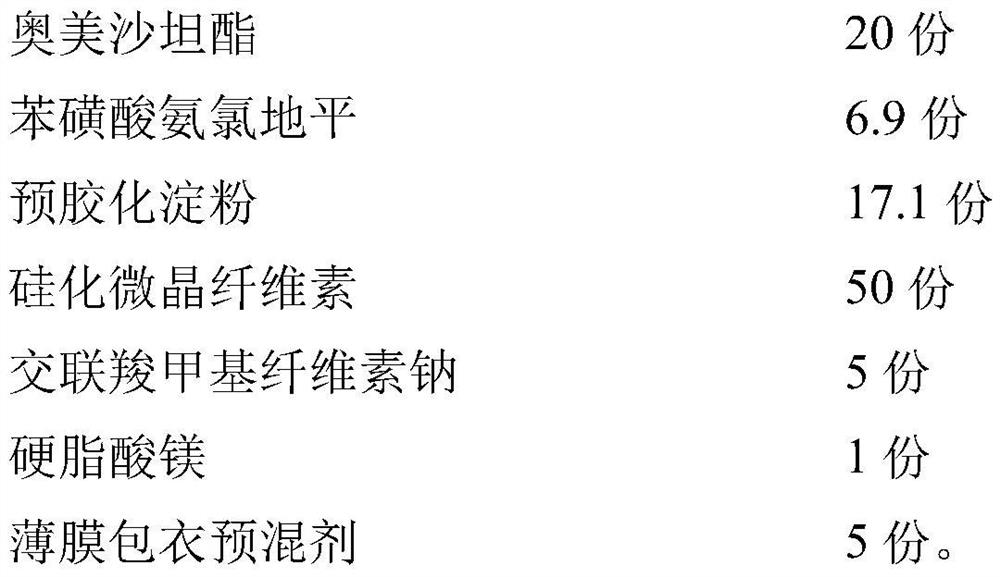

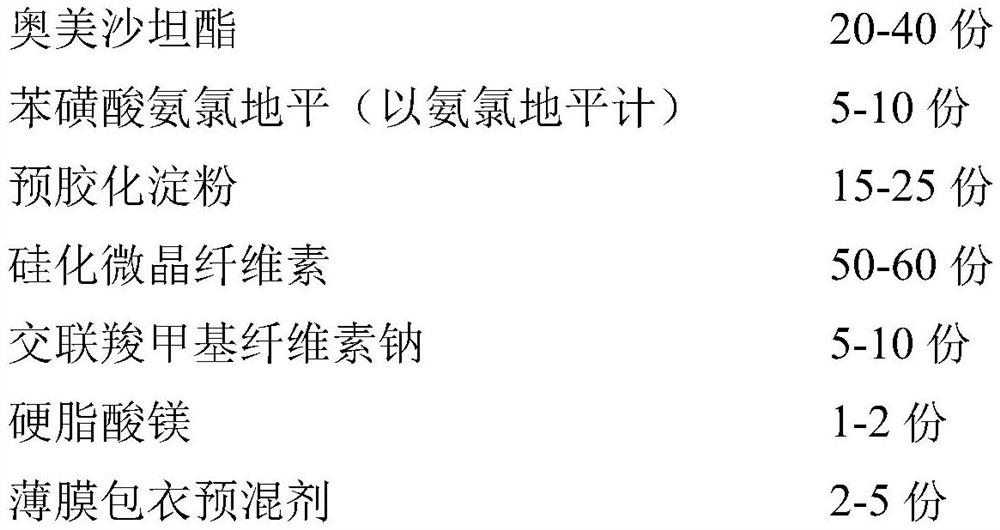

[0045] Formulate a prescription composition of 1000 tablets

[0046]

[0047]

[0048] making process:

[0049] 1) Processing of raw materials: pulverizing olmesartan medoxomil to control particle size D 90 ≤40μm; crush amlodipine besylate to control particle size D 90 ≤70μm.

[0050] The particle size detection results of raw materials are shown in Table 1

[0051] Table 1

[0052]

[0053] It can be seen from Table 1 that the raw material particle sizes of olmesartan medoxomil and amlodipine besylate all meet the requirements.

[0054] 2) Premixing of raw and auxiliary materials: olmesartan medoxomil, amlodipine besylate, pregelatinized starch, silicified microcrystalline cellulose, and croscarmellose sodium were mixed in a mixer, and then sieved through a 1.5mm sieve, continue mixing;

[0055] 3) Dry granulation: the pre-mixed material is prepared into granules ...

Embodiment 2

[0066] Embodiment 2, angle of repose measurement result

[0067] The angle of repose of the blended materials of Example 1, Comparative Example 1, and Comparative Example 2 was measured, and the results are shown in Table 3. After Example 1 and Comparative Example 2 were granulated by dry method, the fluidity of the blend was good; in Comparative Example 1, the powder was directly mixed, and the fluidity of the blend was poor.

[0068] table 3

[0069]

Embodiment 3

[0070] Embodiment 3, mixing uniformity measuring result

[0071] The mixing uniformity of the total blending in Example 1 all met the requirements, and the mixing uniformity of the total blending in Comparative Example 2 did not meet the requirements, which was related to the different particle sizes of the raw materials.

[0072] Mixing uniformity inspection, the results are shown in Table 4.

[0073] Table 4

[0074]

[0075]

[0076] For the mixing uniformity of the two active ingredients, Example 1 satisfies RSD%≤3.0%, indicating that the mixing is uniform; Comparative Example 2 does not meet RSD%≤3.0%, and the mixing is uneven.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com