High-pressure sprayed surface long-acting antibacterial agent

A technology of antibacterial agent and antibacterial synergist, which is applied in the field of surface long-acting antibacterial agents, can solve the problems of reduced antibacterial effect, difficulty in meeting demand, and short antibacterial effect, and achieve good compatibility, improve the drug properties of antibacterial agents, and improve The effect of the antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

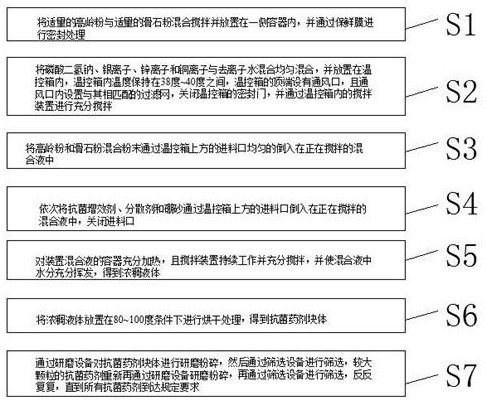

Method used

Image

Examples

preparation example Construction

[0030] The surface long-acting antibacterial agent of high pressure spraying according to the embodiment of the present invention and preparation method thereof, comprise the raw material of following percentage:

[0031] Kaolin powder 10~15%, talc powder 5~8%, deionized water 50~60%, sodium dihydrogen phosphate 8~12%, silver ion 5~10%, zinc ion 3~5%, copper ion 3~ 5%, antibacterial synergist 4~8%, dispersant 4~8%, borax 1~3%;

[0032] Wherein the dispersant includes one or both of sodium oleate, sulfate ester salt, sulfonate and polyol type.

Embodiment 1

[0034] A high-pressure sprayed surface long-acting antibacterial agent, comprising the following percentages of raw materials:

[0035] Kaolin powder 10%, talc powder 5%, deionized water 50%, sodium dihydrogen phosphate 8%, silver ion 5%, zinc ion 3%, copper ion 3%, antibacterial synergist 4%, dispersant 4% , borax 1%;

[0036] Wherein said dispersant comprises sodium oleate 2% and polyol type 2%.

Embodiment 2

[0038] A high-pressure sprayed surface long-acting antibacterial agent, comprising the following percentages of raw materials:

[0039] Kaolin powder 12%, talcum powder 6.5%, deionized water 55%, sodium dihydrogen phosphate 10%, silver ion 7.5%, zinc ion 4%, copper ion 4%, antibacterial synergist 6%, dispersant 6% , Borax 2%;

[0040] Wherein said dispersant comprises sulfate ester salt 3% and polyol type 3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com