High-thrust axial flow pump motor with efficient cooling function

A technology of electric motor and axial flow pump, applied in the field of high thrust axial flow pump motor, can solve the problems of high temperature, increased output power of vertical motor, damage of vertical motor parts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

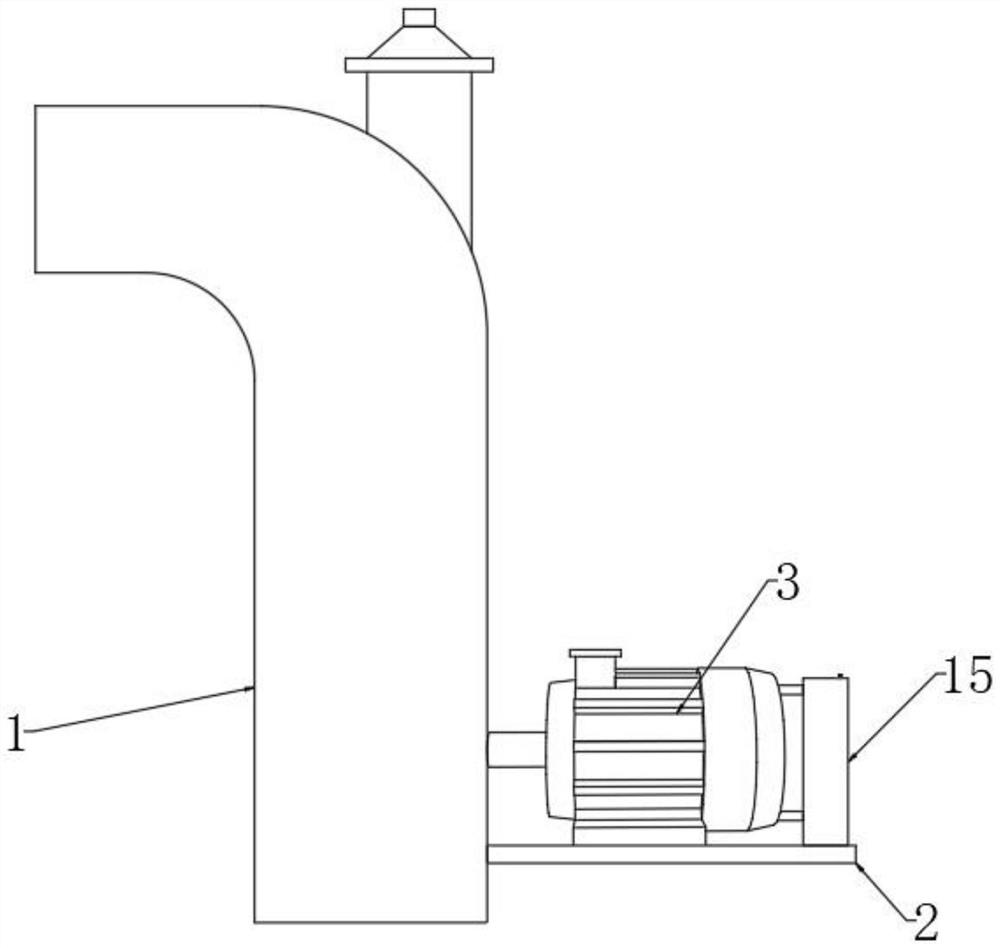

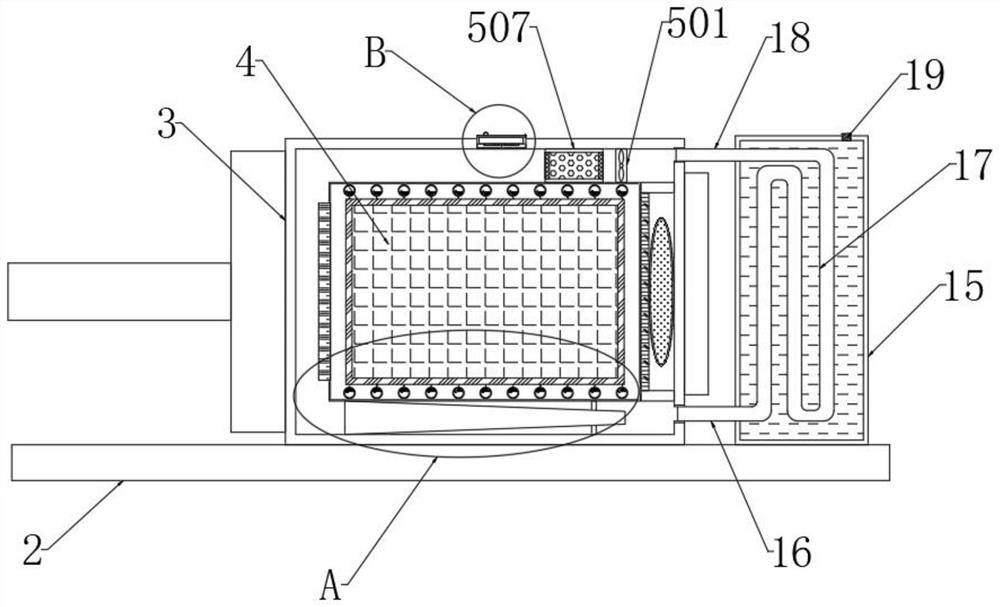

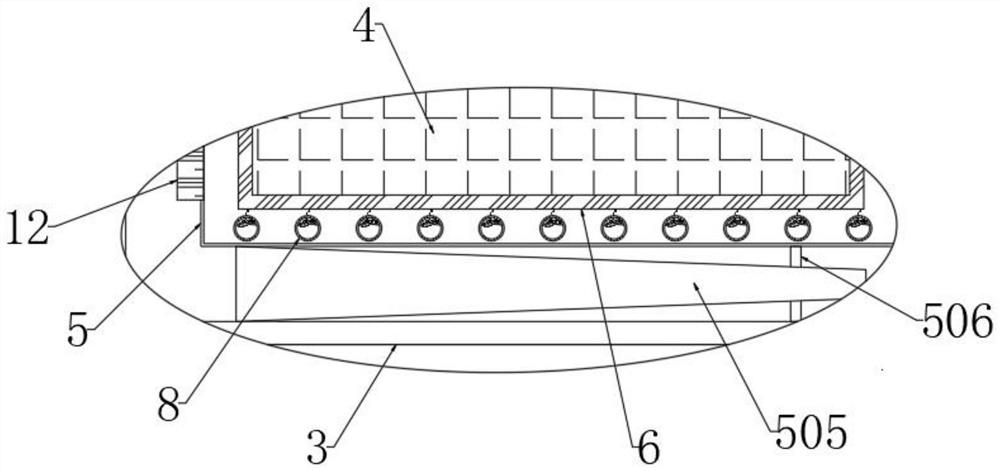

[0041] see Figure 1-5 , a high-thrust axial-flow pump motor with high-efficiency cooling, including an axial-flow pump body 1, a load-bearing platform 2 is fixedly connected to the right end of the axial-flow pump body 1, a motor 3 is fixedly connected to the upper end of the load-bearing platform 2, and the motor 3 is fixed inside The motor internal component 4 is connected, the outer end of the motor internal component 4 is covered with a fixed frame 5, the inner bottom of the fixed frame 5 is fixedly connected with a graphene frame 6, the graphene frame 6 is located at the outer end of the motor internal component 4, and the graphene frame 6 The outer ends are fixedly connected with two sets of symmetrical compression springs 7, the compression springs 7 are made of memory alloy material, the upper end of the compression springs 7 is fixedly connected with the air bag 8, the air bag 8 is filled with aqueous solution, and the outer end of the air bag 8 is installed with mult...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com