Raman laser capable of realizing precise wavelength tuning through temperature control

A Raman laser and temperature controller technology, applied in the field of lasers, can solve problems such as inability to generate wavelengths and single output wavelength, and achieve the effects of low cost, simple structure, and improved light conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

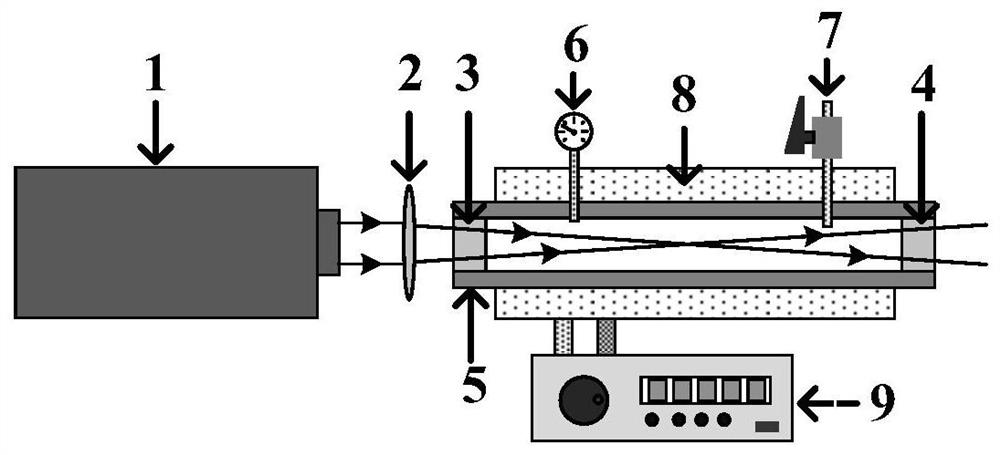

[0042] Such as figure 1 As shown, a Raman laser whose output wavelength is finely tuned by gas temperature adjustment produces first-order Stokes lasing. A solid-state Nd:YAG laser with an output wavelength of 1064nm is used to pump methane to generate a Raman laser that can be finely tuned at around 1543nm.

[0043] According to the attached figure 1 , the working process of the Raman laser is as follows:

[0044] The first step: the pump laser is focused and input into the Raman cell;

[0045] Step 2: The temperature of the methane gas in the Raman cell can be adjusted through the temperature control module;

[0046] Step 3: Use a wavelength meter to detect the output Raman laser, and set a reasonable methane gas temperature according to the wavelength.

[0047] For example: the density of methane is 0.15g / cm 3 The corresponding relationship between temperature and Raman frequency shift is shown in the table below

[0048]

[0049]

Embodiment 2

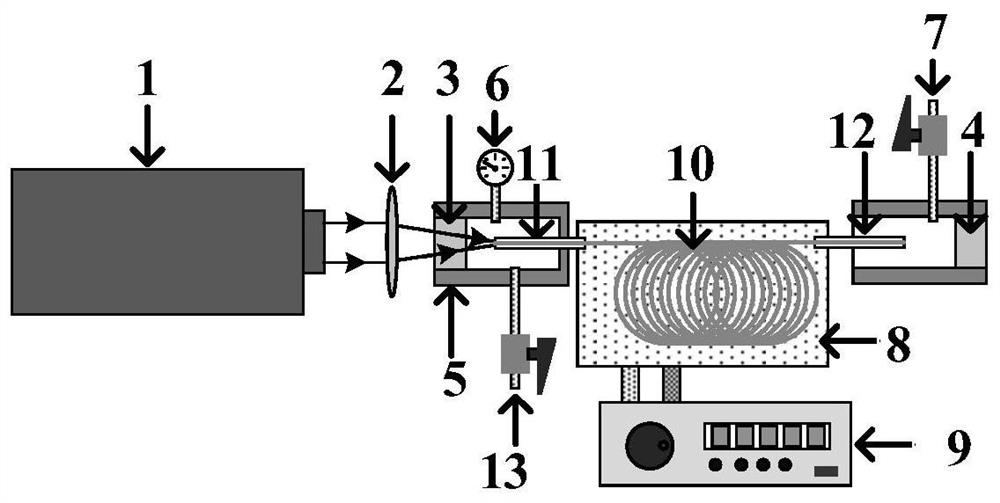

[0051] IPG's commercialized fiber laser is used as the pump laser source with a wavelength of 1070nm. figure 2 The design scheme can focus and collect the IPG fiber laser into the hollow-core photonic crystal fiber, fill the Raman cell with high-purity methane, convert the 1070nm wavelength laser to 2840nm, and then realize the Raman by adjusting the temperature of the methane gas. The Mann wavelength is finely tuned around 2840nm. For example, when the temperature range is -100-300°C, the tuning of the Raman laser wavelength at about 2831-2849nm can be realized.

Embodiment 3

[0053] according to figure 2 The design scheme, the hollow-core photonic crystal fiber is added to the Raman cell to reduce the threshold of stimulated Raman and achieve high-efficiency conversion of the pump laser.

[0054] The implementation process of this scheme can be as follows: use the 532nm laser as the pump laser, fill the Raman cell with high-purity nitrogen gas, collect the 532nm pump laser into the hollow-core photonic crystal fiber through the focusing lens, and pass the gas The temperature control can realize the fine tuning of the Raman laser wavelength around 607nm. For example, when the temperature range is -100-100°C, the Raman laser wavelength can be tuned around 602-610nm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com