Freeze-drying-based lithium ion battery positive electrode lithium supplementing method and product

A technology for lithium-ion batteries and lithium supplementation, applied in battery electrodes, non-aqueous electrolyte battery electrodes, secondary batteries, etc., can solve the problems of high oxidation and decomposition potentials, achieve the effects of simplifying the process, promoting uniform dispersion, and reducing the decomposition voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

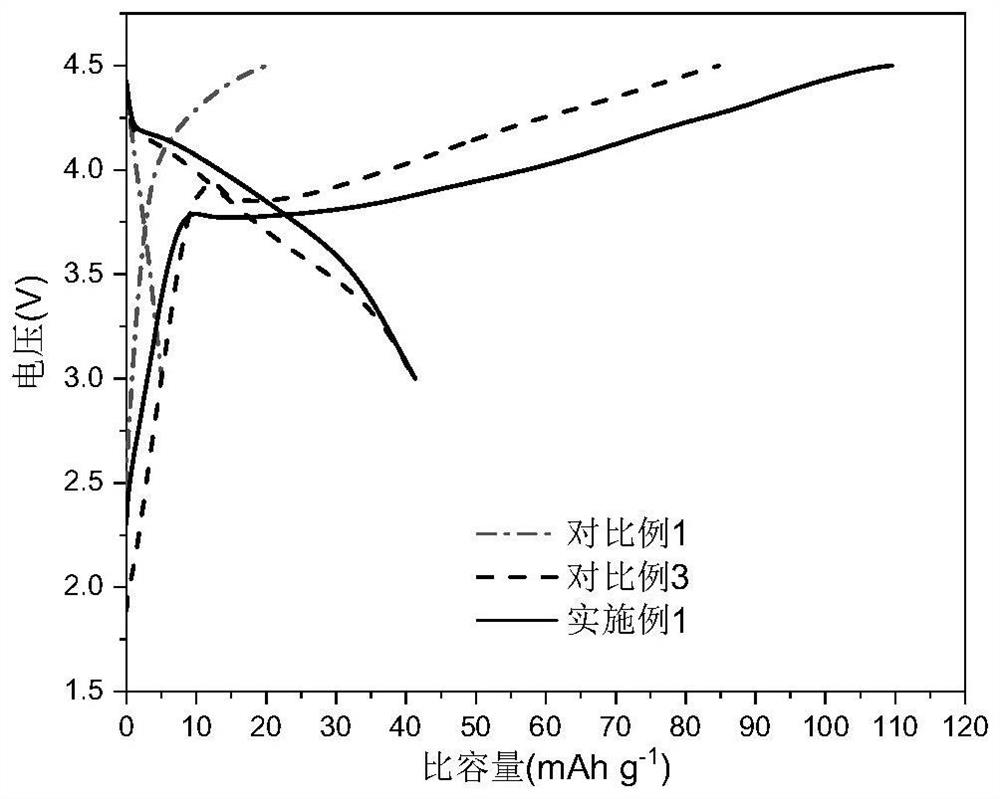

[0045] 1. Prepare lithium oxalate-rich positive pole pieces to test their decomposition voltage:

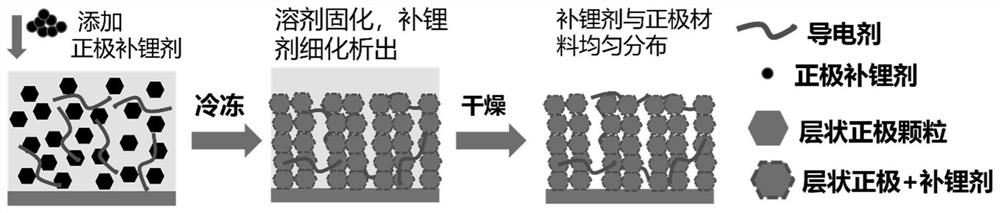

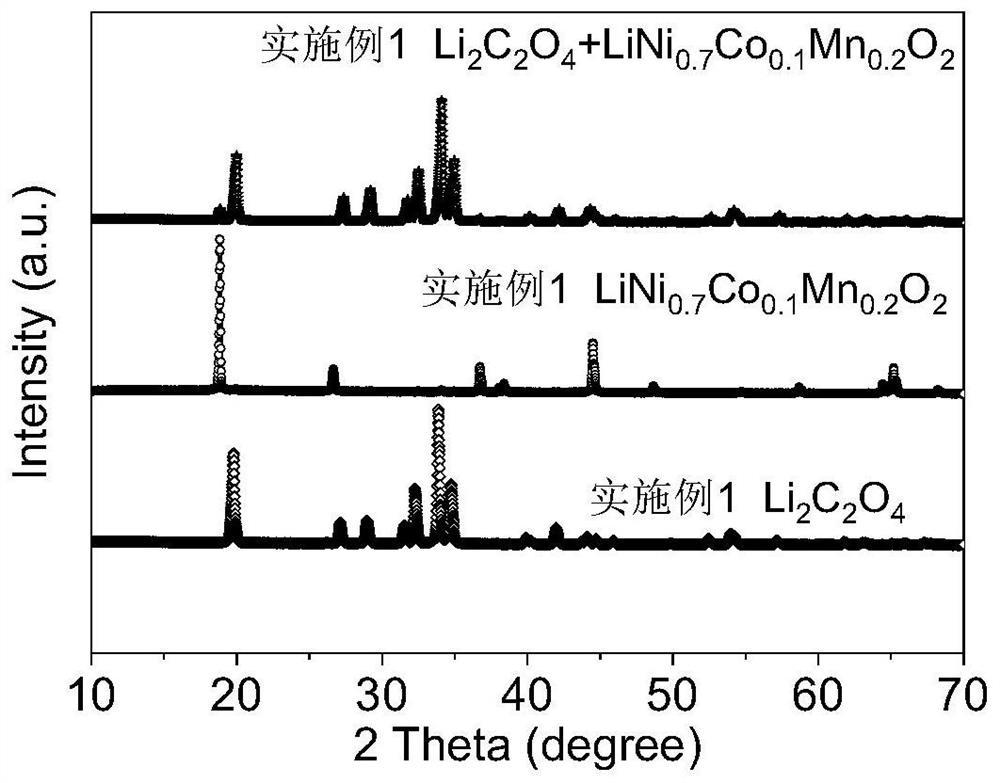

[0046] Lithium oxalate, positive electrode active material LiNi 7 co 1 mn 2 o 2 , Conductive agent KB800 and carboxymethyl cellulose are dispersed in deionized water according to the ratio of mass ratio 0.6:0.1:0.2:0.1 and mixed evenly in Zhongyi disperser, so that lithium oxalate is dissolved, and the solid content of the slurry obtained is 45wt. %. The prepared slurry was coated on the current collector. Put the wet pole piece in a low-temperature environment of -60°C, freeze for 3 hours, and dry the pole piece under a low pressure of -10°C and 5 Pa for 12 hours to prepare a pole piece with fine and uniform distribution of lithium supplementation agent. And the metal lithium assembled battery is tested for the first effect. The pole pieces before and after rolling were prepared into SEM samples, and the morphology of the surface and cross section were observed respectivel...

Embodiment 2

[0050] The positive electrode active material LiNi 7 co 1 mn 2 o 2 , lithium oxalate, conductive agent KB800 and carboxymethyl cellulose are dispersed in deionized water according to the mass ratio of 0.85:0.0.05:0.0.05:0.05 and mixed evenly in Zhongyi disperser to dissolve lithium oxalate in deionized In water, the solid content of the slurry obtained was 45wt.%. Other conditions were the same as in Example 1.

Embodiment 3

[0052] The positive active material is lithium cobaltate, and other conditions are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com