Method for improving anti-loosening performance of thread pair and auxiliary spring washer thereof

A secondary anti-loosening and anti-loosening washer technology, applied in the direction of threaded fasteners, screws, nuts, etc., can solve the difference in the preloading installation process, without specific instructions, without clearly pointing out, from a certain position or preload force when to start waiting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

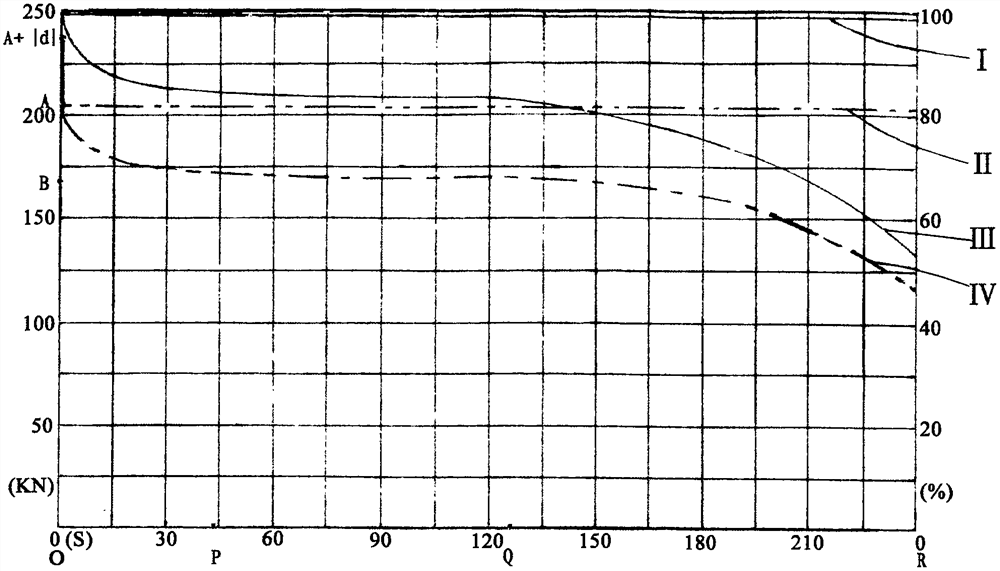

[0041] figure 1 Among them, the clamping force curve of the present invention is shown in curve II, which is an approximately horizontal straight line, and in the first stage, it is a curve in the OP section, and there is no fast-falling residual pre-tightening force, but has been kept close to The pretightening force of A value; the second stage is the curve in the PQ section, with the increase of the number of vibrations, it still maintains an almost horizontal state; there is no third stage of the QR section's loosening, fatigue, and fracture rapid decline stage, the entire curve OR segment is ideal.

[0042] Curve I is the percentage of residual clamping force of the present invention, and the percentage of residual clamping force of the present invention is relatively high, close to 100%.

[0043] Curve IV is an example of the change curve of the clamping force in the prior art. It can be clearly seen that the clamping force of the first stage OP section rapidly decrease...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com