Semi-underground subway station construction technology and semi-underground subway station

A construction technology and technology for subway stations, which are applied in artificial islands, water conservancy projects, underwater structures, etc., to achieve the effects of not affecting traffic, reducing carbon emissions, and ensuring the safety of building envelopes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

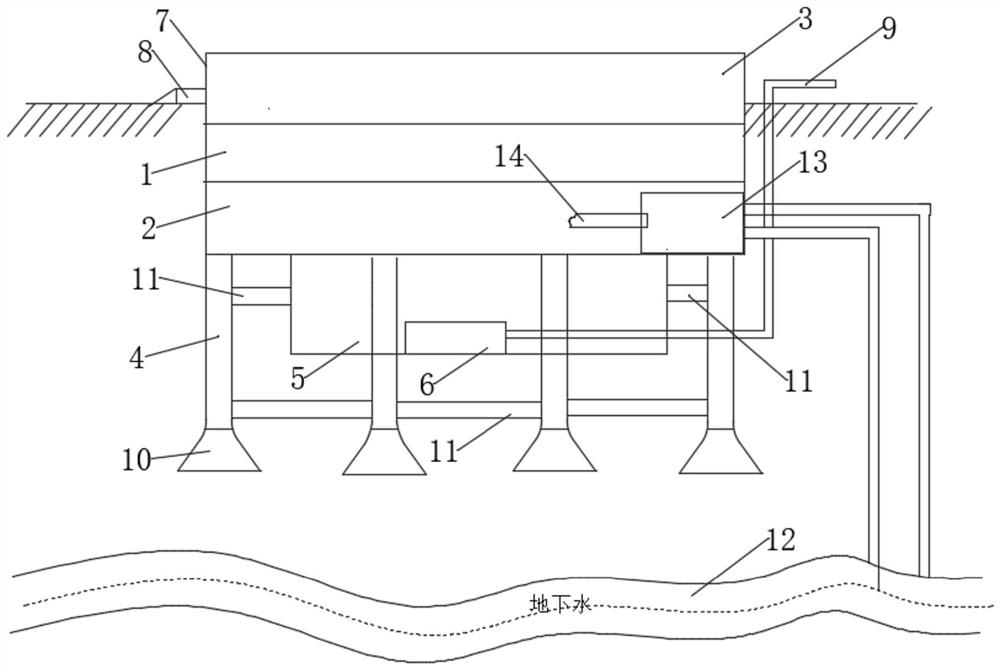

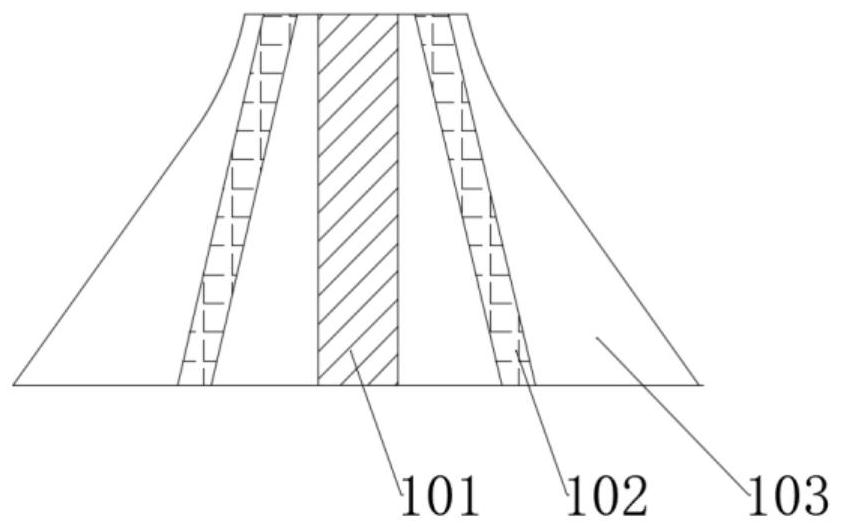

[0051]A semi-underground subway station, the semi-underground subway station at least includes a negative floor, a train floor, a station hall floor and pile foundations, the negative floor and the train floor are all underground, and the lower half of the station hall floor Part is located underground, the upper half of the station hall floor is located on the ground, and the negative floor is set on multiple pile foundations;

[0052] Also comprise water air-conditioning system, described water air-conditioning system comprises underground water source 12, water air-conditioning system 13 and windpipe 14 (filtering device is arranged between underground water source and water air-conditioning system, groundwater is filtered and then transported to water air-conditioning system), the heat of the underground water source 12 is transported to the negative floor 1 or / and the driving deck floor 2 or / and the station hall floor 3 through the water air-conditioning system 13 and the ...

Embodiment 2

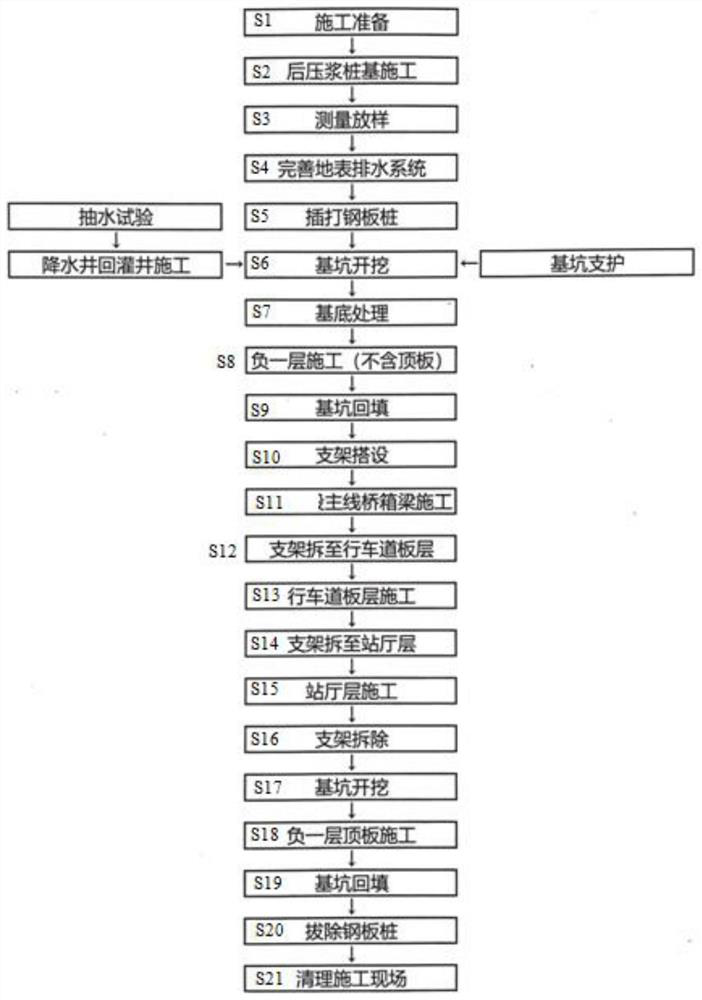

[0056] The semi-underground subway station in embodiment 1 adopts following construction technology to carry out construction;

[0057] Such as Figure 1~3 Shown, a kind of construction technique of semi-underground subway station of the present invention, a kind of construction technique of semi-underground subway station, described semi-underground subway station at least comprises negative layer 1, driving board layer 2, station hall layer 3, pile foundation 4 and Drainage chamber 5;

[0058] The drainage chamber 5 is located at the bottom, and a drainage pump 6 is arranged inside the drainage chamber 5, and the drainage pump 6 discharges the accumulated water to the ground through the drainage pipe 9; the entrance and exit 7 of the station hall floor 1 are set higher than the ground platform 8;

[0059] The drainage pump is powered by a battery, which effectively avoids the drainage pump not working properly due to power failure in rainy weather, and the battery is charg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com