Preparation method of chitosan fiber non-woven fabric applied to surface layer of paper diaper

A technology of chitosan fiber and non-woven fabrics, applied in wet spinning, stretch spinning, fiber chemical characteristics, etc., can solve the problems of poor prevention of diaper rash and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

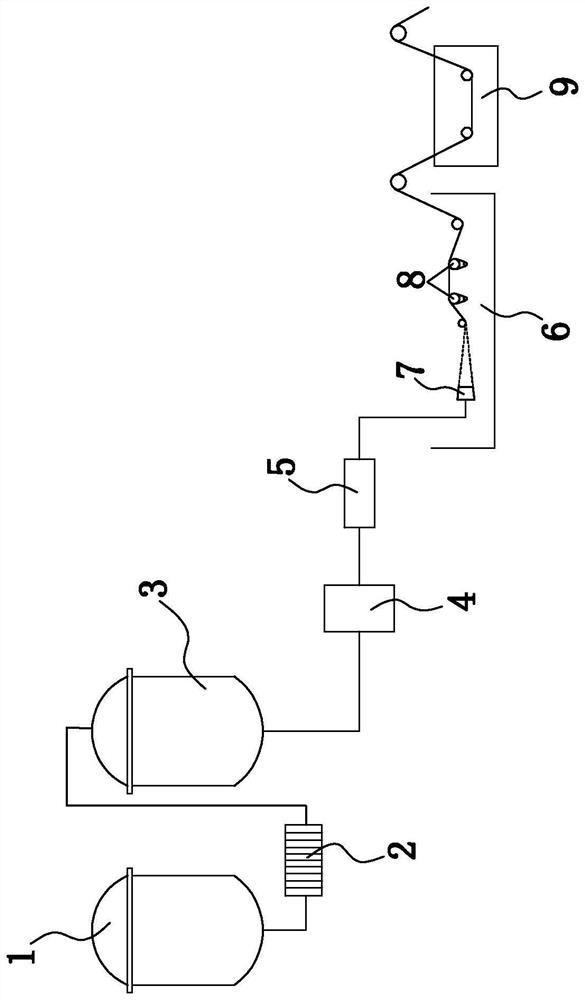

Method used

Image

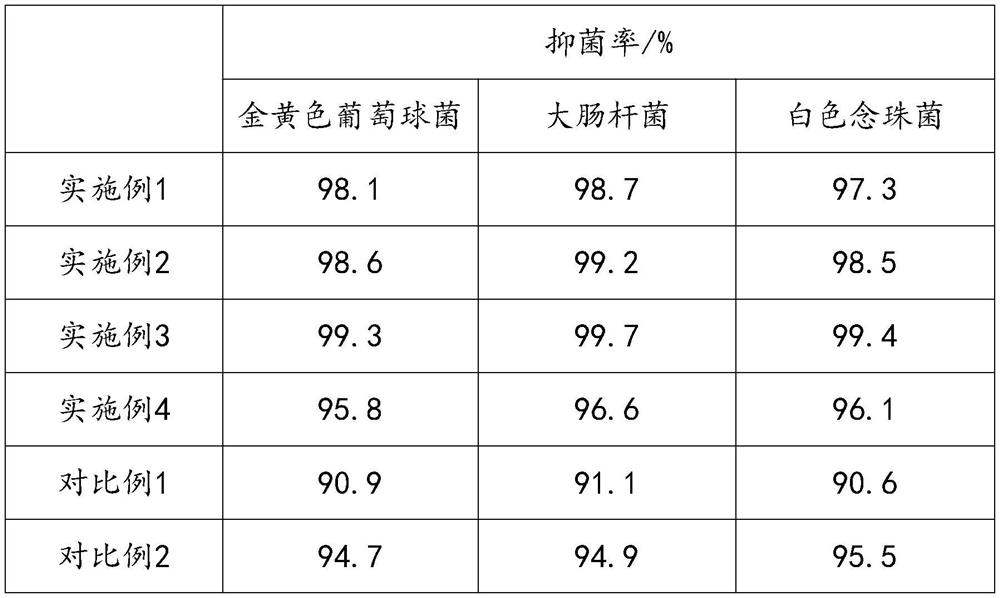

Examples

Embodiment 1

[0042] Method for preparing chitosan fiber nonwoven fabric applied to the surface of the diaper surface, including the following steps:

[0043] 1) Preparation of N-carboxyethyl chitosan

[0044] 20 g of a 20 g of an acetamin is 95% chitosan, 80 ml of acrylic acid and 1000 ml of distilled water to a three flask, and stirred and dissolved, and then the mixed liquid pH is 5.8-6.3, and magnetically stirred at 85 ° C temperature conditions for 8 h; reaction After the end, it was cooled to room temperature, precipitated with acetone, separated from centrifugation, and then dissolved in a small amount of water, precipitated again and centrifugally, and centrifugally, it was repeated three times, collecting the product, and placed the product in a culture dish In the case of filter paper, it is placed in a vacuum oven in a vacuum oven at a vacuum oven to react to constant weight, i.e., N-carboxyethyl chitosan;

[0045] Dehydrazine 95% chitosan feedstock, by viscosity method, it is measur...

Embodiment 2

[0060] Method for preparing chitosan fiber nonwoven fabric applied to the surface of the diaper surface, including the following steps:

[0061] 1) Preparation of N-carboxyethyl chitosan

[0062] 20 g of a 20 g of a deacetylate was 95% chitosan, 80 ml of acrylic acid and 1000 ml of distilled water to a three flask, and stirred and dissolved, and then the mixture pH of 5.8-6.3 was adjusted, and the magnetic force was stirred at 88 ° C temperature conditions; reaction After the end, it was cooled to room temperature, precipitated with acetone, separated from centrifugation, and then dissolved in a small amount of water, precipitated again and centrifugally, and centrifugally, it was repeated three times, collecting the product, and placed the product in a culture dish In the case of filter paper, it is placed in a vacuum oven in a vacuum oven at a vacuum oven to react to constant weight, i.e., N-carboxyethyl chitosan;

[0063] 2) Preparation of modified chitosan

[0064] N-carboxyet...

Embodiment 3

[0075] Method for preparing chitosan fiber nonwoven fabric applied to the surface of the diaper surface, including the following steps:

[0076] 1) Preparation of N-carboxyethyl chitosan

[0077] 20 g of a 20 g of a deacetyl is 95% chitosan, 80 ml of acrylic acid and 1000 mL of distilled water into a three flask, and stirred and dissolved, and then the mixed liquid pH is 5.8-6.3, and the magnetic force is stirred at 90 ° C temperature conditions for 5 h; reaction After the end, it was cooled to room temperature, precipitated with acetone, separated from centrifugation, and then dissolved in a small amount of water, precipitated again and centrifugally, and centrifugally, it was repeated three times, collecting the product, and placed the product in a culture dish In the case of filter paper, it is placed in a vacuum oven in a vacuum oven at a vacuum oven to react to constant weight, i.e., N-carboxyethyl chitosan;

[0078] 2) Preparation of modified chitosan

[0079] N-carboxyethyl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Denier | aaaaa | aaaaa |

| Fiber strength | aaaaa | aaaaa |

| Denier | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com