Thick pattern-free hot-dip galvanized steel coil and preparation method thereof

A galvanized steel, no flower heat technology, used in heat treatment equipment, hot dip plating process, heat treatment process control, etc. , poor surface quality and other problems, to achieve the effect of good quality, improving the coil shape of galvanized finished products, and ensuring uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

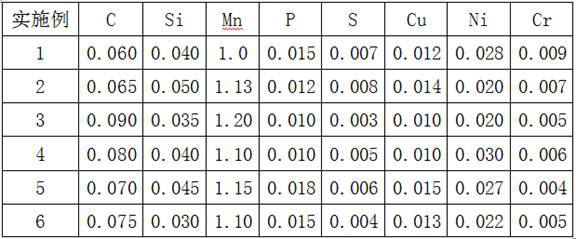

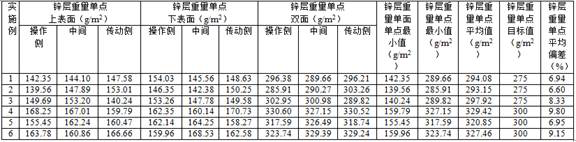

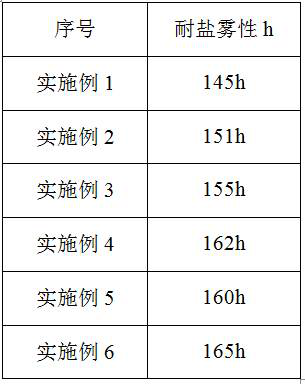

[0029] A kind of thick-gauge pattern-free hot-dip galvanized steel coil, the chemical composition and mass percentage of the galvanized steel coil substrate are shown in Table 1, and the preparation method of the above-mentioned heat-based galvanized steel coil is as follows:

[0030] a: Smelting process: the molten steel conforming to the composition of the steel coil is smelted, refined, and continuously cast to obtain a slab;

[0031]b: Steel rolling process: the slab enters the steel rolling process, and after heating, rough rolling, finishing rolling, laminar cooling and coiling, hot-rolled coils are obtained;

[0032] c: pickling process: hot-rolled coils enter the pickling process, and pickled coils are obtained through pickling, rinsing and crimping;

[0033] d: Galvanizing process: pickling coils enter the galvanizing process, and undergo laser welding, annealing in an annealing furnace, galvanizing, air knife purging, post-plating cooling, skin finishing and crimping...

Embodiment 2

[0045] A kind of thick-gauge pattern-free hot-dip galvanized steel coil, the chemical composition and mass percentage of the galvanized steel coil substrate are shown in Table 1, and the preparation method of the above-mentioned heat-based galvanized steel coil is as follows:

[0046] a: Smelting process: the molten steel conforming to the composition of the steel coil is smelted, refined, and continuously cast to obtain a slab;

[0047] b: Steel rolling process: the slab enters the steel rolling process, and after heating, rough rolling, finishing rolling, laminar cooling and coiling, hot-rolled coils are obtained;

[0048] c: pickling process: hot-rolled coils enter the pickling process, and pickled coils are obtained through pickling, rinsing and crimping;

[0049] d: Galvanizing process: pickling coils enter the galvanizing process, and undergo laser welding, annealing in an annealing furnace, galvanizing, air knife purging, post-plating cooling, skin finishing and crimpin...

Embodiment 3

[0061] A kind of thick-gauge pattern-free hot-dip galvanized steel coil, the chemical composition and mass percentage of the galvanized steel coil substrate are shown in Table 1, and the preparation method of the above-mentioned heat-based galvanized steel coil is as follows:

[0062] a: Smelting process: the molten steel conforming to the composition of the steel coil is smelted, refined, and continuously cast to obtain a slab;

[0063] b: Steel rolling process: the slab enters the steel rolling process, and after heating, rough rolling, finishing rolling, laminar cooling and coiling, hot-rolled coils are obtained;

[0064] c: pickling process: hot-rolled coils enter the pickling process, and pickled coils are obtained through pickling, rinsing and crimping;

[0065] d: Galvanizing process: pickling coils enter the galvanizing process, and undergo laser welding, annealing in an annealing furnace, galvanizing, air knife purging, post-plating cooling, skin finishing and crimpin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com