Steel slag waste heat comprehensive utilization and f-CaO grading digestion method and system

A steel slag and waste heat technology, applied in the field of resource utilization of steel slag, can solve the problems of poor stability of steel slag, achieve high stability, improve energy efficiency, and reduce operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

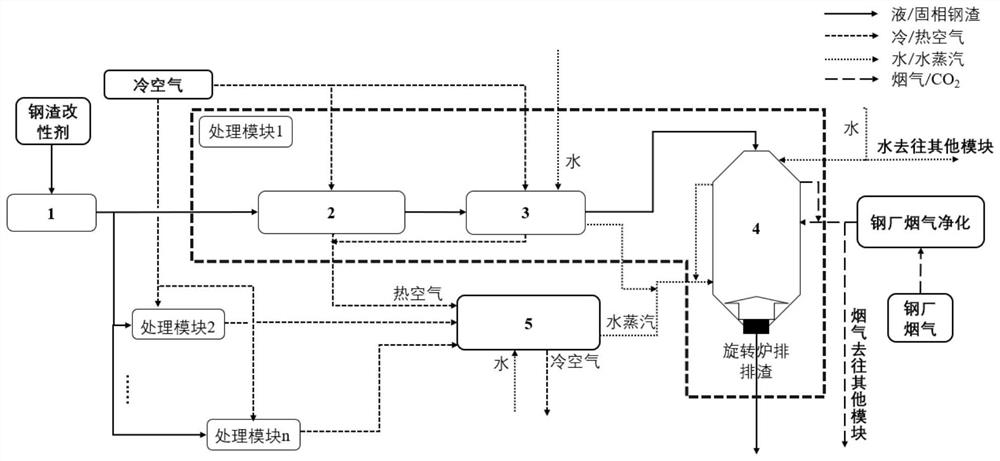

[0034] A comprehensive utilization of steel slag waste heat and f-CaO graded digestion system, such as figure 1 As shown, the overall use of the concept of source quenching and tempering, particle size control, and process intensification improves the comprehensive utilization rate of waste heat in steel slag and the f-CaO digestion rate. Including the following steps:

[0035] Source quenching and tempering: pour the molten steel slag into the molten steel slag buffer 1, add a certain amount of silicon-containing steel slag modifiers such as fly ash, iron tailings, etc. into the molten steel slag buffer 1, pass Liquid mixing is carried out mechanically, so that the added steel slag modifier reacts with the f-CaO in the steel slag, thereby reducing the f-CaO content in the steel slag;

[0036] Particle size control: through the centrifugal granulator 2, the modified steel slag is centrifugally granulated and the particle size is controlled by adjusting the centrifugal speed, ...

Embodiment 2

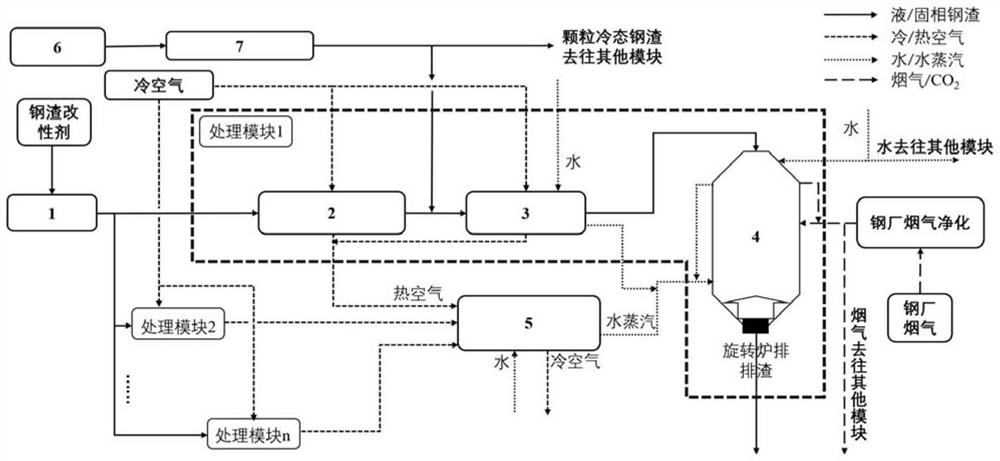

[0043] Such as figure 2 As shown, a steel slag waste heat comprehensive utilization and f-CaO graded digestion system includes a cold steel slag buffer 6 and a cold steel slag breaker 7 . Pour the cold steel slag piled up in the steel plant into the cold steel slag buffer 6, which is connected to the cold steel slag breaker 7. The steel slag is mixed, and the cold steel slag is heated by the waste heat of the steel slag, and then enters the heat exchange moving bed 3, and the subsequent process operation is carried out in sequence, which can process a large amount of existing cold steel slag and realize the resource utilization of solid waste.

Embodiment 3

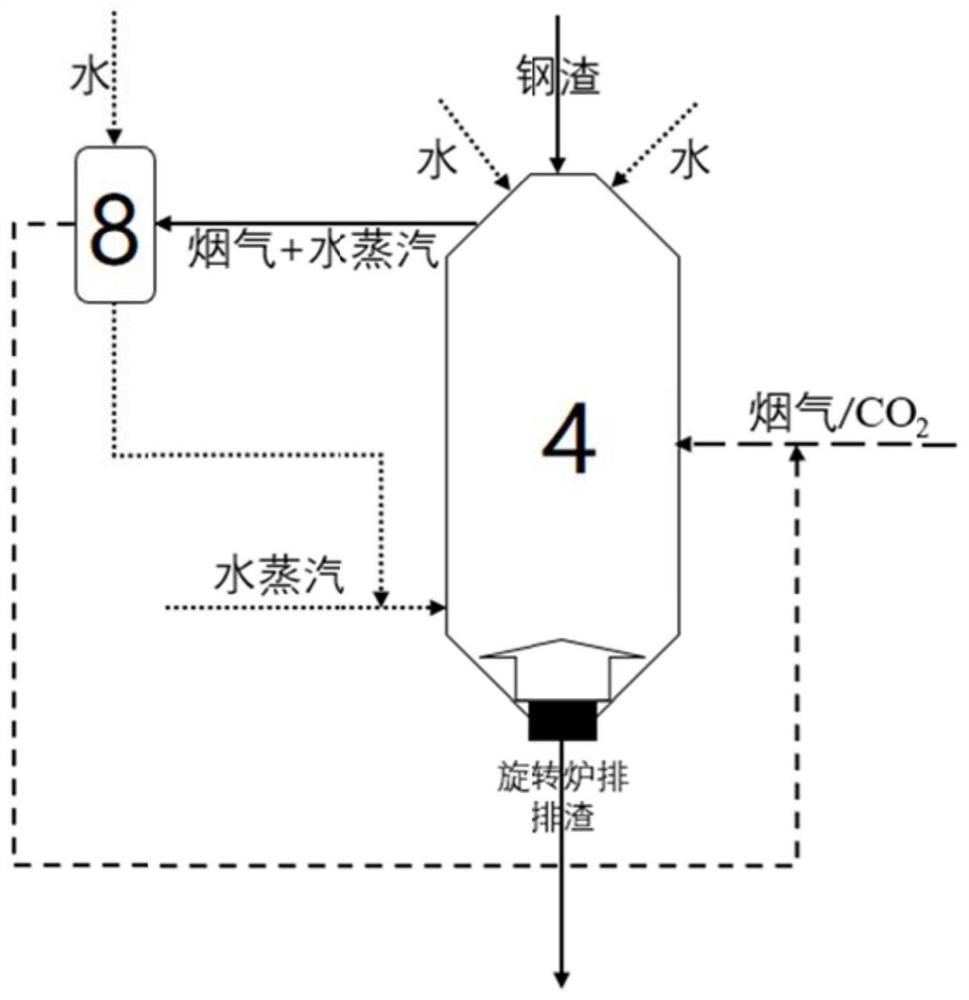

[0045] Such as image 3 As shown, the scrubber 8 is used to treat the flue gas / CO from the top of the pressurized moving bed 4 2 Separated from the steam mixture flow, the water introduced into the scrubber 8 can realize CO 2 It is separated from water vapor and connected to the pressurized moving bed through pipelines for recycling.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com