Bamboo plywood for container bottom plate and preparation method of bamboo plywood

A technology for container floor and bamboo plywood, which is applied in chemical instruments and methods, adhesives, mechanical equipment, etc., can solve the problems of mechanical properties, poor moisture resistance, fast growth rate of bamboo, and short time to form, and achieve excellent mechanical properties, Good softness and elasticity, long open time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

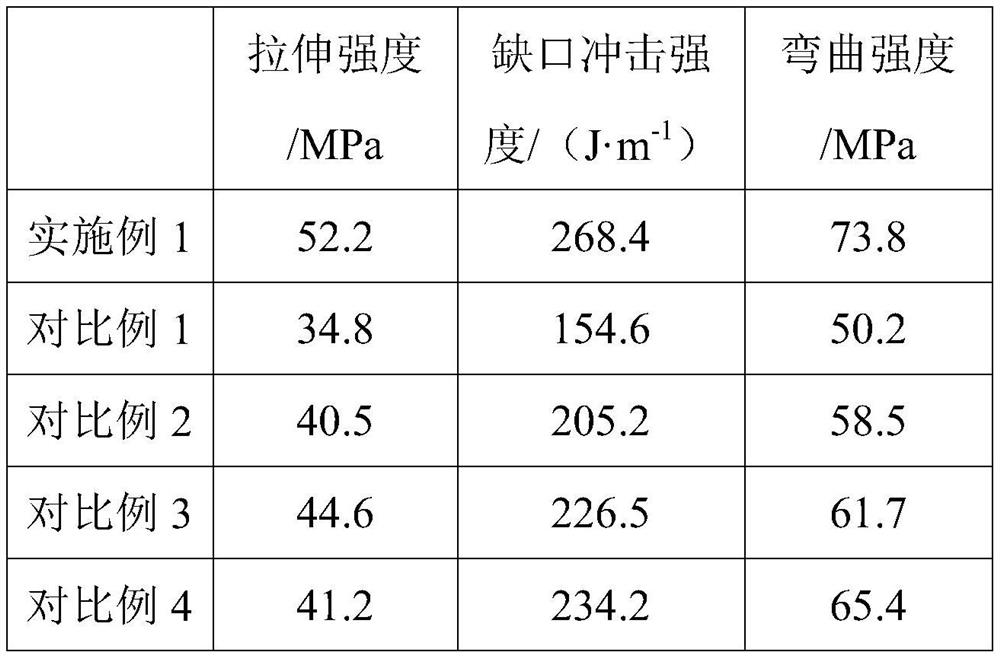

Examples

Embodiment 1

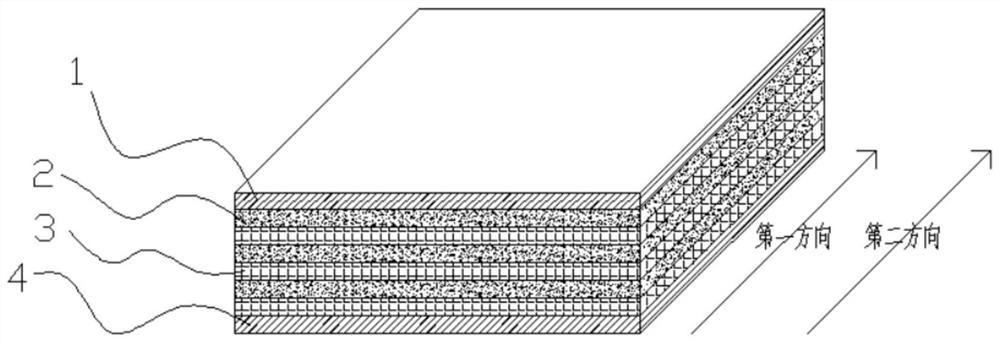

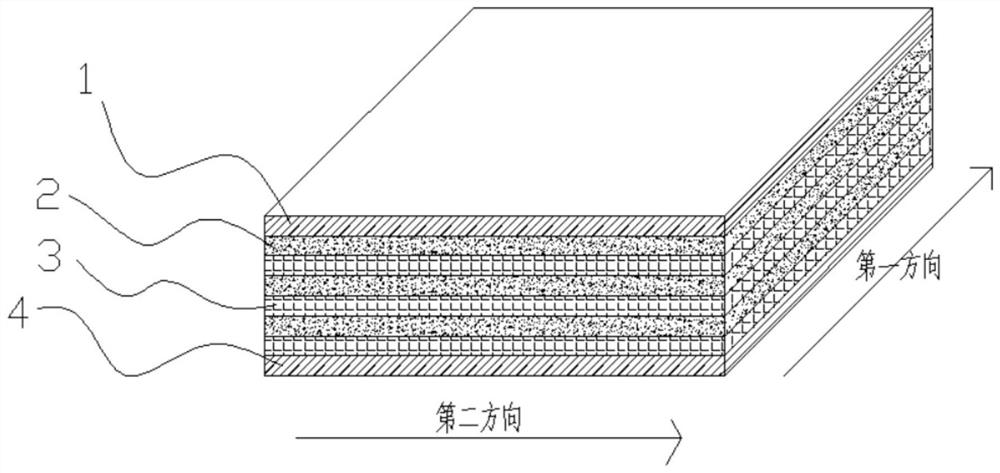

[0027] refer to figure 1 , a kind of bamboo plywood for container bottom plate, comprise upper layer (1), lower layer (4) and be located at the bamboo base layer between described upper layer (1), lower layer (4), bamboo base layer is formed by The first bamboo board layer (2) arranged in the first direction and the second bamboo board layer (3) arranged in the second direction are composed, the first direction and the second direction are parallel to each other, and the first bamboo board layer (2) The number of layers is the same as that of the second bamboo board layer (3), both are 3 layers, and the first bamboo board layer (2) and the second bamboo board layer (3) are arranged staggered along the thickness direction, the upper layer (1), the lower layer The layer (4), the first bamboo board layer (2) and the second bamboo board layer (3) are connected by an adhesive.

[0028] Among them, the upper layer (1) and the lower layer (4) are made of the same material, and are c...

Embodiment 2

[0035] It is basically the same as Embodiment 1, except that the first direction and the second direction are perpendicular to each other.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com