Processing technology of thrust pad base of shield motor

A processing technology and shielded motor technology, applied in metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve problems such as inaccurate indexing, unstable operation, and different bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] A shielded motor thrust tile processing technology, comprising the following steps:

[0023] a) Clean the thrust Wawaji 6, and check the surface condition without bump damage;

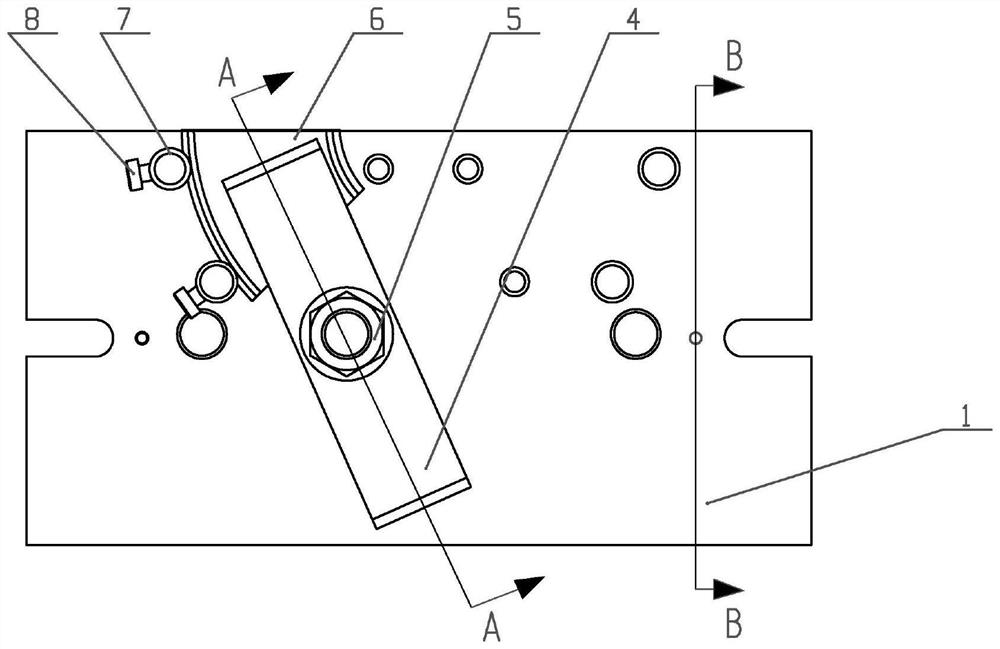

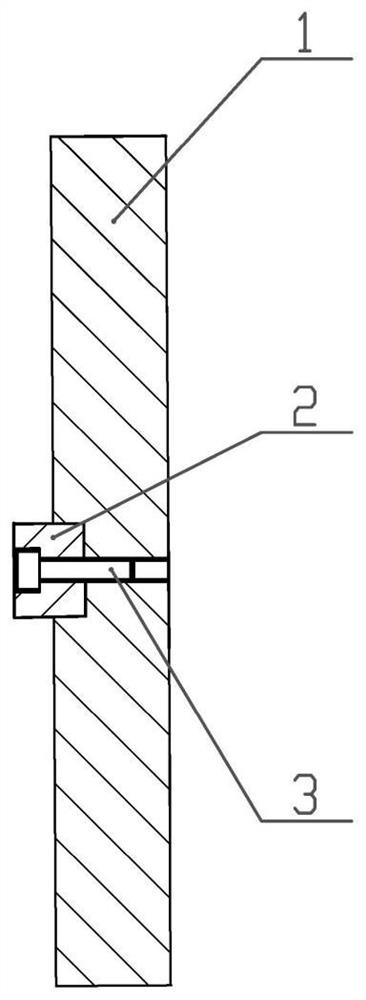

[0024] b) if figure 1 As shown, place the thrust tile base 6 on the foundation plate 1, and use the positioning pin 9 to locate the position of the pin hole of the thrust tile base 6;

[0025] c) Screw two fixing pins 7 into the base plate 1, the fixing pins 7 are in contact with the tile base 6, and screw the set screws 8 into the fixing pins 7;

[0026] d) Use the set screw 8 to adjust the position of the thrust tile base 6, so that the length of the thrust tile base 6 protruding from the edge of the foundation plate 1 is consistent, and tighten the set screw 8;

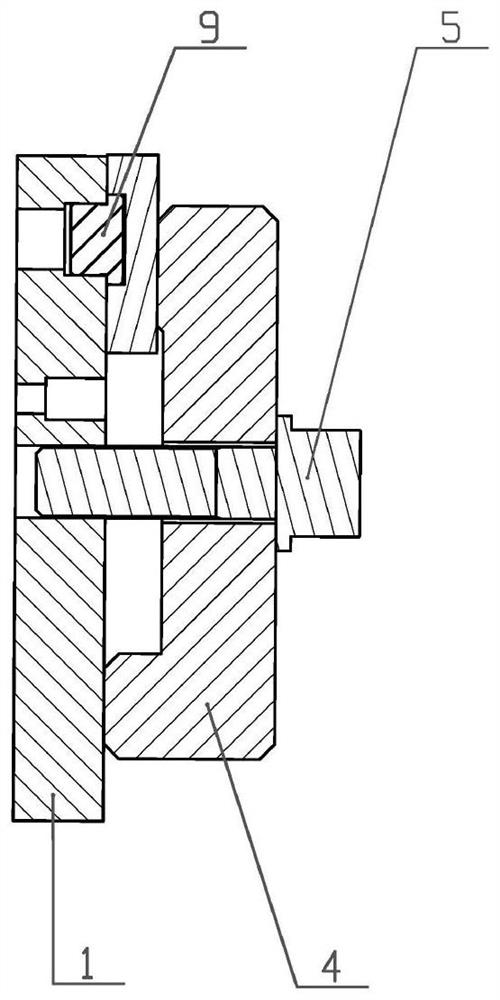

[0027] e) if figure 2 As shown, place the pressure plate 4 on the surface of the thrust tile base 6 and fix it with the screw 5, and do not damage the surface of the thrust tile base 6;

[0028] f) Place the base plate 1 assembl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com