Preparation method of amphoteric ion exchange resin for extracting precious metal through hydrometallurgy

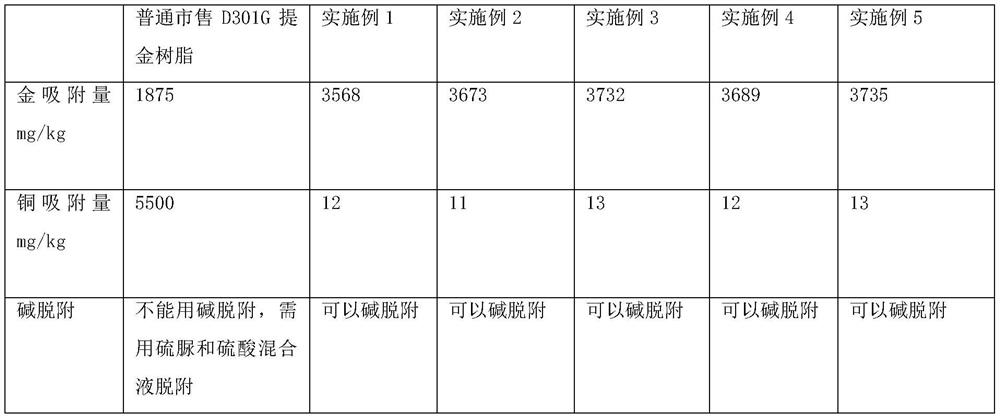

A technology of amphoteric ion and exchange resin, which is applied in the direction of amphoteric ion exchange, ion exchange, chemical instruments and methods, etc. It can solve the problems of harsh resin regeneration conditions and low adsorption capacity, and achieve good mechanical strength, large specific surface area, and good adsorption performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] 1) Prepare polymer microspheres, add 100g deionized water, 10g magnesium sulfate, 10g sodium carbonate, 1.5g sodium lignosulfonate, 1.5g hydroxyethyl cellulose, 3g sodium chloride in a 3L three-necked flask, 3g sodium nitrite;

[0025] 100 g of styrene, 10 g of divinylbenzene, 0.1 g of benzoyl peroxide, and 70 g of isobutanol were added again. After the oil phase and the water phase are mixed, the temperature is controlled at 60°C, the mechanical stirring speed is 117 rpm, and the particle size is adjusted; the temperature is raised to 80°C and kept for 1 hour; the temperature is raised to 82°C and kept for 4 hours; the temperature is raised to 90°C for distillation , remove the porogen, wash with hot water multiple times, dry and sieve to obtain polymer microspheres;

[0026] 2) The polymer microspheres are subjected to chloromethylation, the polymer microspheres are placed in 200g of chloromethyl ether, 50g of anhydrous zinc chloride is added, 20g of sulfuric acid is...

Embodiment 2

[0030] 1) Prepare polymer microspheres, add 100g deionized water, 0.5g magnesium sulfate, 0.5g sodium carbonate, 0.05g sodium lignosulfonate, 0.05g hydroxyethyl cellulose, 20g chloride Sodium, 5g sodium nitrite;

[0031] 100 g of styrene, 1 g of divinylbenzene, 8 g of benzoyl peroxide, and 20 g of isobutanol were added again. After the oil phase and the water phase are mixed, the temperature is controlled at 60°C, the mechanical stirring speed is 117 rpm, and the particle size is adjusted; the temperature is raised to 80°C and kept for 1 hour; the temperature is raised to 82°C and kept for 4 hours; the temperature is raised to 90°C for distillation , remove the porogen, wash with hot water multiple times, dry and sieve to obtain polymer microspheres;

[0032] 2) The polymer microspheres are subjected to chloromethylation, the polymer microspheres are placed in 200g of chloromethyl ether, 10g of anhydrous zinc chloride is added, 70g of sulfuric acid is added dropwise while sti...

Embodiment 3

[0036] 1) Prepare polymer microspheres, add 100g deionized water, 5g magnesium sulfate, 5g sodium carbonate, 1g sodium lignosulfonate, 1g hydroxyethyl cellulose, 10g sodium chloride, 4g sodium bicarbonate in a 3L three-necked flask sodium nitrate;

[0037] 100 g of styrene, 5 g of divinylbenzene, 4 g of benzoyl peroxide, and 45 g of isobutanol were added again. After the oil phase and the water phase are mixed, the temperature is controlled at 60°C, the mechanical stirring speed is 117 rpm, and the particle size is adjusted; the temperature is raised to 80°C and kept for 1 hour; the temperature is raised to 82°C and kept for 4 hours; the temperature is raised to 90°C for distillation , remove the porogen, wash with hot water multiple times, dry and sieve to obtain polymer microspheres;

[0038] 2) The polymer microspheres are subjected to chloromethylation, the polymer microspheres are placed in 200g of chloromethyl ether, 30g of anhydrous zinc chloride is added, 45g of sulfu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com