BiVO4/MoS2-coated GO composite photocatalytic material as well as preparation method and application thereof

A composite photocatalysis, dosage ratio technology, applied in catalyst activation/preparation, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc. , Green environmental protection treatment technology, the effect of high-efficiency treatment technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] (1)MoS 2 Preparation of:

[0044] Put 0.992g ammonium molybdate tetrahydrate and 1.824g thiourea into 100mL deionized water, stir for 30min until completely mixed; transfer to a 150mL autoclave, heat at 230°C for 22h; Wash with water and absolute ethanol several times, dry in a vacuum oven for 8 hours, and grind to collect powder samples.

[0045] Get 480mg powder sample, add in the mixed solution of 1200mL deionized water and ethanol (V 去离子水 :V 乙醇 =3:1), ultrasonically stirred for 8h, stood overnight, collected the precipitate, and dried it in a vacuum oven for 8h to obtain MoS 2 .

[0046] (2) Preparation of GO:

[0047] Put 100mL of concentrated sulfuric acid in a 1000mL beaker and place them together in an ice-water bath at 0°C, then add 2g of expandable graphite powder and 1g of analytically pure NaNO to it 3 , stirred for 30min. After stirring, slowly add 6g of analytically pure KMnO to the beaker several times in small amounts 4 , Stir for 2 hours to mix ...

Embodiment 2

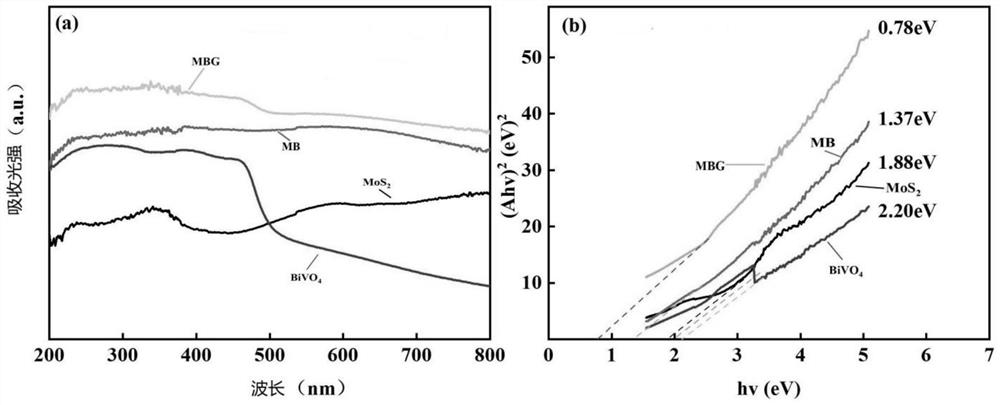

[0057] In this example, the BiVO 4 / MoS 2 BiVO in @GO Composite Photocatalyst 4 、MoS2 The effect of different proportions of GO and GO on the catalytic performance of the composite catalyst.

[0058] Adopt the method described in embodiment 1 to prepare MoS 2 And GO, spare. Control MoS 2 And the addition amount of GO is constant, changes Bi(NO) in embodiment 1 step (3) 3 ·5H 2 The amount of O, PVP, ethylene glycol and 3-mercaptopropionic acid was used to adjust BiVO 4 in BiVO 4 / MoS 2 The proportion of @GO composite photocatalyst is 50-90%. The specific inspection steps are as follows:

[0059] Bi(NO) 3 ·5H 2 Dissolve O and PVP in ethylene glycol, mix well by ultrasonic, then add 3-mercaptopropionic acid, stir and mix well, then adjust the pH to get BiVO 4 ;

[0060] Then to BiVO 4 Add prepared GO and MoS 2 , stir and mix evenly, add 25mL ammonium metavanadate aqueous solution with a concentration of 4.624g / L, stir, then heat at 180°C for 1 hour, cool to room t...

Embodiment 3

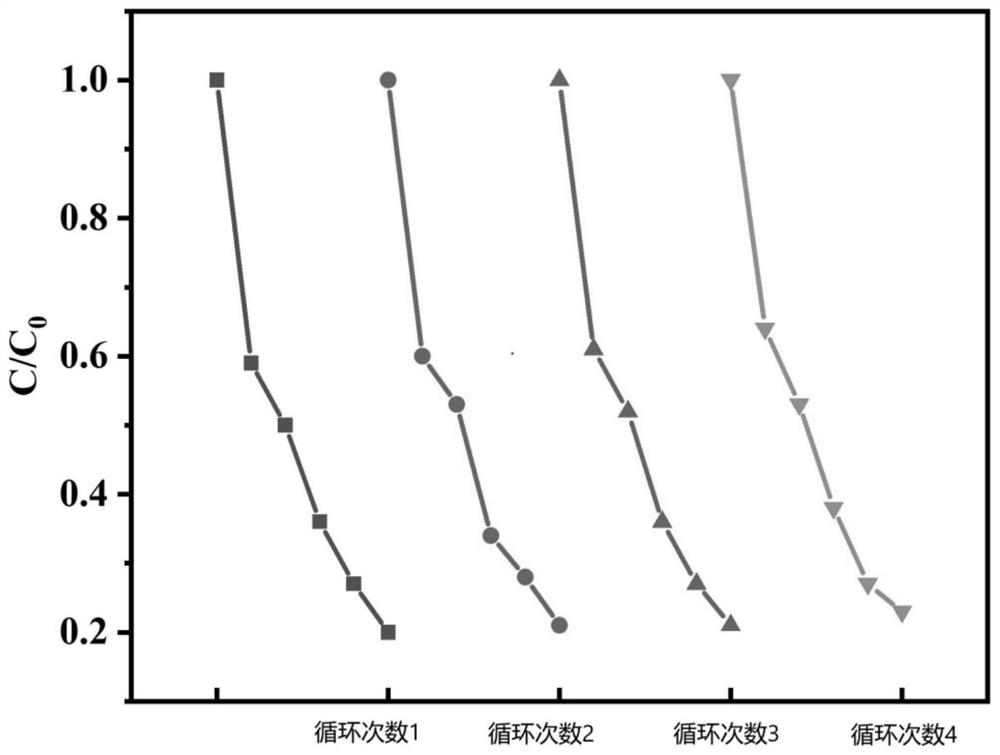

[0066] In order to determine the stability of the material, the BiVO prepared in Example 1 4 / MoS 2 The @GO composite photocatalytic material has been subjected to a cycle experiment, and the experimental results are as follows: image 3 shown. After the tetracycline solution was degraded, the precipitate was collected by centrifugation, washed several times with water and ethanol, and dried in a vacuum oven for 8 hours. When the mass of the catalyst was less than 0.1 g, a new catalyst was added.

[0067] image 3 for BiVO 4 / MoS 2 Cyclic degradation diagram of @GO composite photocatalyst. It can be seen from the figure that the degradation rate of the catalyst is still 78.4% after four cycles, indicating that the prepared photocatalyst has good stability.

PUM

| Property | Measurement | Unit |

|---|---|---|

| catalytic efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com