Preparation method of MOFs and polymer bicontinuous mixed matrix membrane

A technology of mixed matrix membranes and polymers, applied in separation methods, chemical instruments and methods, membrane technology, etc., can solve the problems of inability to guarantee high loading of MOFs materials, poor membrane selectivity, low mechanical properties, etc., and achieve improved permeation selectivity , enhanced mechanical properties, high load effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

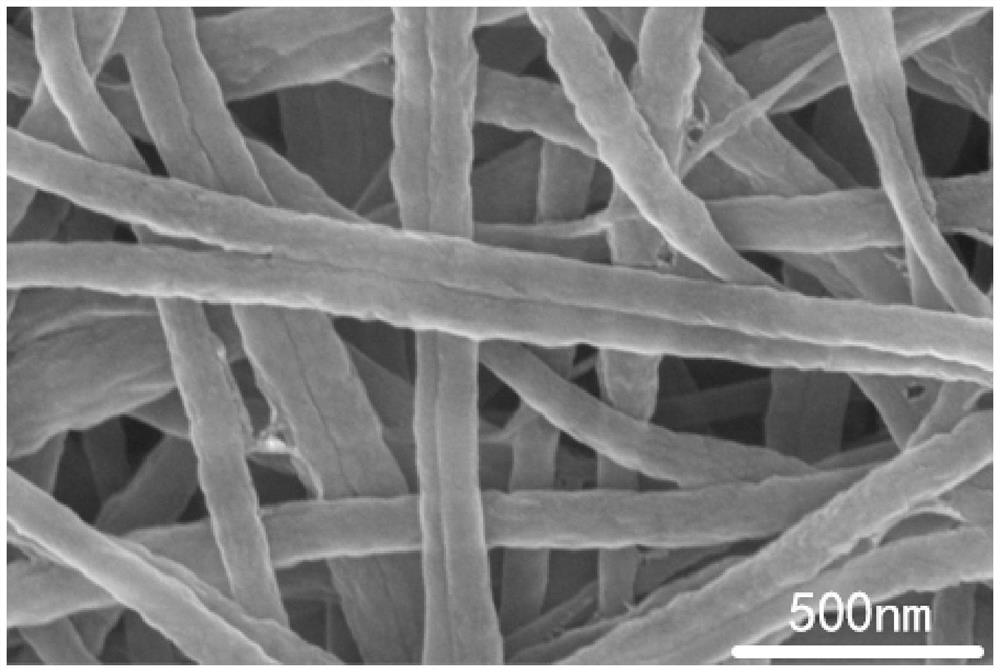

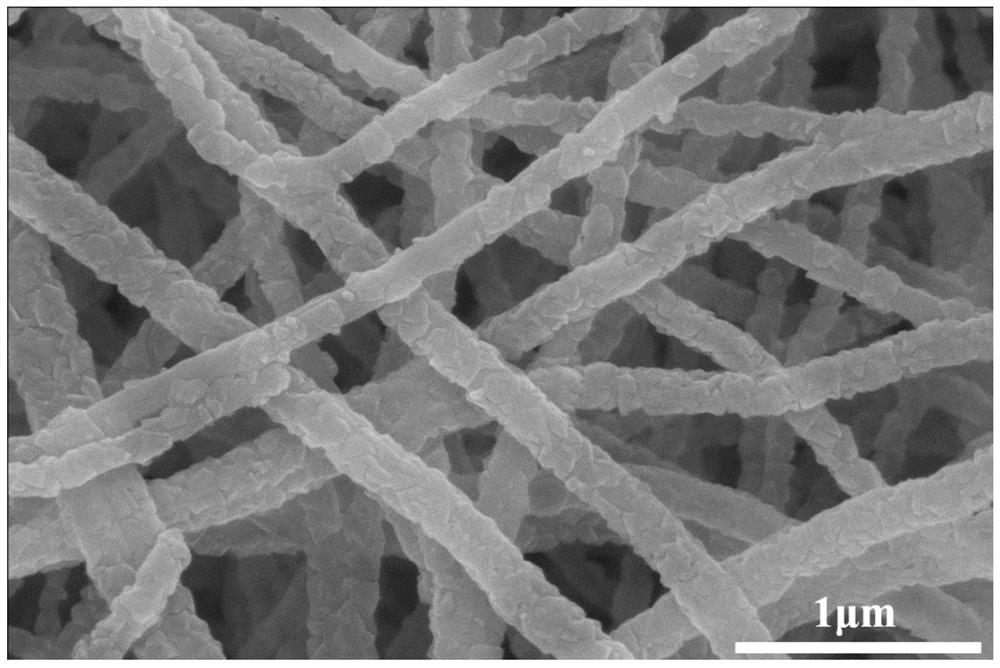

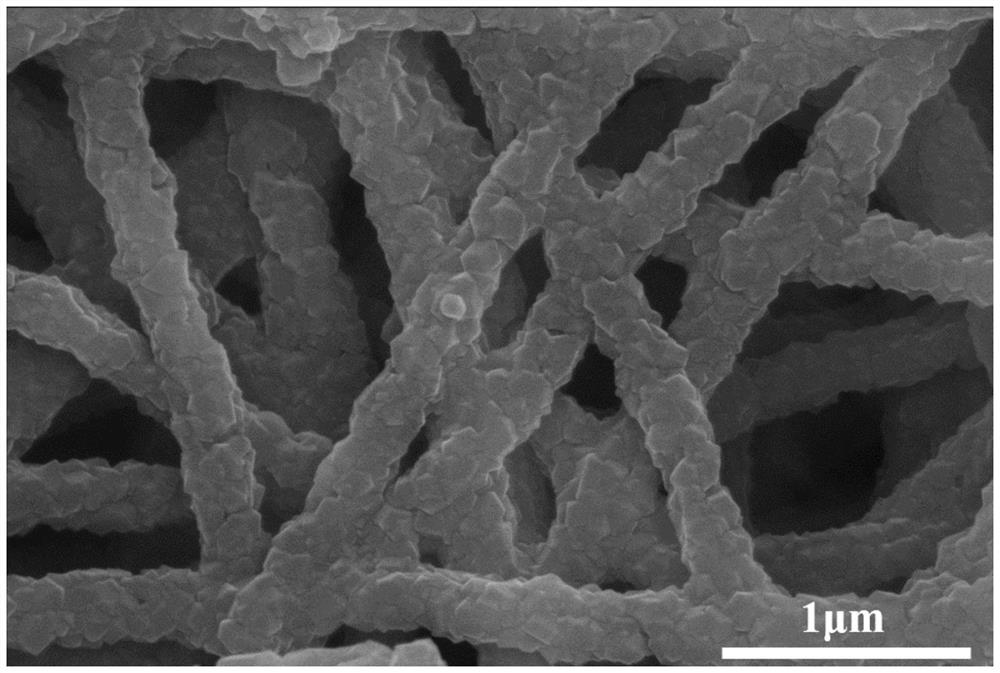

[0023] Preparation of ZIF-8 nanofiber material: the Zn(Ac) of 1.0g 2 2H 2 O metal salt particles were added to 10ml of N,N-dimethylformamide (DMF) solvent, stirred to dissolve completely, and the water bath was ultrasonicated for 15min to expel air bubbles. Then 1.0 g of polyacrylonitrile (PAN) powder was added thereto, and stirred vigorously at room temperature for 24 h to completely dissolve it. Transfer the resulting spinning solution into a 10 mL disposable syringe, using a 22-gauge needle, and place it on the electrospinning apparatus. Control the bolus injection speed to 1mL / h, the distance between the needle and the receiver to 18cm, the speed of the receiver to 80r / h, the operating environment temperature to 20°C, the air humidity to 40%, the positive voltage of the spinning machine to be 16KV, and the negative voltage to be 1.5KV. Wrap aluminum foil over the receiver to receive the fibers. The obtained composite fiber was vacuum-dried at 50 °C for 12 h to remove r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com