Collagen dressing and preparation method thereof

A sticking and collagen technology, which is applied in the field of preparation of sterile collagen dressings, can solve the problems of high production requirements, high level of cytotoxicity, and decline in product quality, and achieve the effect of low requirements and low cytotoxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Collagen 0.1 part

[0038] 4 parts glycerin

[0039] Methylparaben 0.01 parts

[0040] Ethylparaben 0.04 parts

[0041] Purified water 95.85 parts

[0042] Total 100 copies

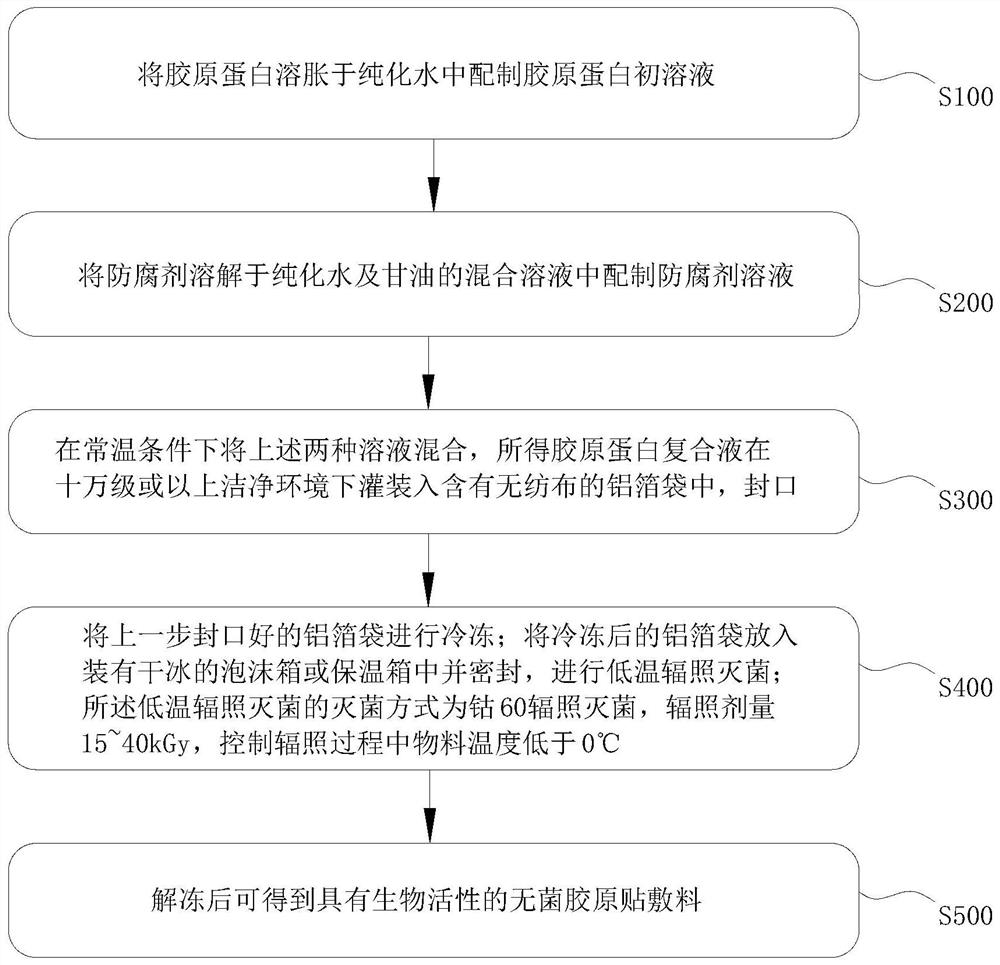

[0043] refer to figure 1 ,Preparation:

[0044] 1) Swell collagen in purified water to prepare initial collagen solution;

[0045] 2) Dissolve the preservative in a mixed solution of purified water and glycerin to prepare a preservative solution;

[0046] 3) Mix the above two solutions at room temperature,

[0047] 4) The obtained collagen compound solution is filled into an aluminum foil bag containing non-woven fabric in a clean environment of class 100,000 or above, and sealed;

[0048] 5) Freeze the aluminum foil bag sealed in the previous step; put the frozen aluminum foil bag into a foam box or an incubator filled with dry ice and seal it, and then sterilize it by low-temperature irradiation. The sterilization method is cobalt 60 irradiation Bacteria, the actual received radiation do...

Embodiment 2

[0052] Collagen 0.1 part

[0053] 4 parts glycerin

[0054] Methylparaben 0.003 parts

[0055] Ethylparaben 0.015 parts

[0056] Purified water 95.882 parts

[0057] Total 100 copies

[0058] Preparation:

[0059] 1) Swell collagen in purified water to prepare initial collagen solution;

[0060] 2) Dissolve the preservative in a mixed solution of purified water and glycerin to prepare a preservative solution;

[0061] 3) Mix the above two solutions at room temperature,

[0062] 4) The obtained collagen compound solution is filled into an aluminum foil bag containing non-woven fabric in a clean environment of class 100,000 or above, and sealed;

Embodiment 3

[0064] Collagen 0.1 part

[0065] 4 parts glycerin

[0066] Methylparaben 0.003 parts

[0067] Ethylparaben 0.015 parts

[0068] Purified water 95.882 parts

[0069] Total 100 copies

[0070] Preparation:

[0071] 1) Swell collagen in purified water to prepare initial collagen solution;

[0072] 2) Dissolve the preservative in a mixed solution of purified water and glycerin to prepare a preservative solution;

[0073] 3) Mix the above two solutions at room temperature,

[0074] 4) The obtained collagen compound solution is filled into an aluminum foil bag containing non-woven fabric in a clean environment of class 100,000 or above, and sealed;

[0075]5) Freeze the aluminum foil bag sealed in the previous step; put the frozen aluminum foil bag into a foam box or an incubator filled with dry ice and seal it, and then sterilize it by low-temperature radiation. The sterilization method is cobalt 60 irradiation Bacteria, the actual received radiation dose is controlled to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com