Colorful FD noodles and preparation method thereof

A noodle and color technology, applied in the field of colored FD noodles and their preparation, can solve the problems of oil and grease, musty smell, etc., and achieve the effects of being easy to store, easy to carry, and prolonging the shelf life at room temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] The present invention provides a method for preparing colored FD noodles described in any one of the above technical solutions, comprising:

[0047] A) mixing wheat flour, starch, gluten, superfine fruit and vegetable powder, gluten enhancer, synergist, antioxidant with water, stirring, and dough, to obtain the first dough and the second dough with different colors;

[0048] B) proofing the first dough and the second dough respectively, ripening, pressing into the first dough sheet and the second dough sheet respectively; the first dough sheet and the second dough sheet are made into noodles through compound calendering;

[0049] C) The noodles are steamed, cut, boiled, cooled, pre-frozen, vacuum freeze-dried, and packaged.

[0050] The invention mixes wheat flour, starch, gluten powder, ultrafine fruit and vegetable powder, gluten-enhancing agent, synergist, antioxidant and water. The present invention does not limit the specific mixing method, as long as those skille...

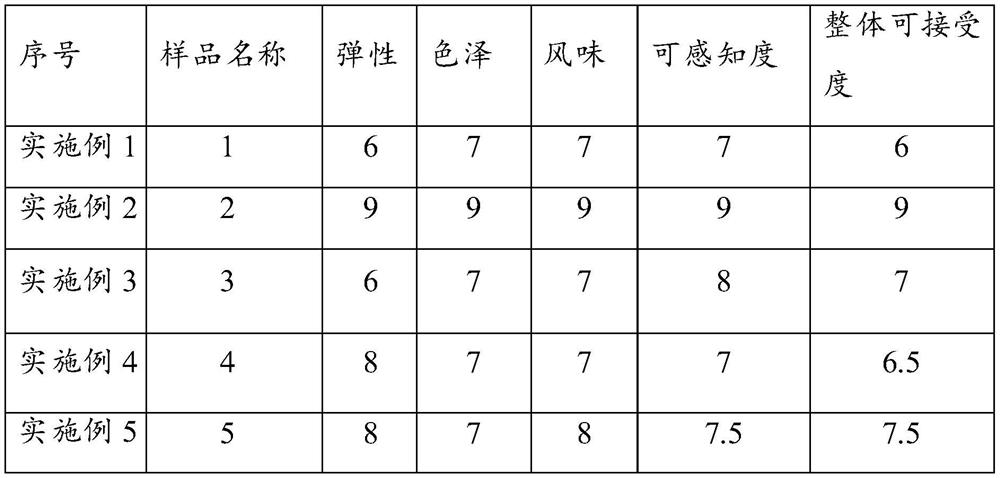

Embodiment 1

[0077] Example 1 Two-color face sheet compound calender front overlapping

[0078] dough making

[0079] Taking 100 parts of wheat flour as benchmark powder, 25 parts of starch, 10 parts of gluten powder, 10 parts of ultrafine seaweed powder, water preparation (3 parts of edible salt, 0.2 parts of gluten enhancer, 0.3 parts of phosphate ((Sodium tripolyphosphate: sodium hexametaphosphate: sodium pyrophosphate=1:1:1)), 0.02 parts by mass of tocopherol, 0.1 parts by mass of D-sodium erythorbate, 0.03 parts by mass of ascorbyl palmitate, 0.05 parts by mass citric acid), 40 parts by mass of water knead the dough, mature, and roll into a 6mm wide green dough sheet through the first roller of the feeding hopper.

[0080] Taking 100 parts of wheat flour as benchmark flour, 25 parts of starch, 10 parts of gluten powder, 10 parts of ultrafine pumpkin powder, water mix (3 parts of edible salt, 0.2 parts of gluten enhancer, 0.3 parts of phosphate ((Sodium tripolyphosphate: sodium hexam...

Embodiment 2

[0084] Embodiment 2 Two-color noodle sheet first calendering overlapping

[0085] The production of the dough sheet is the same as in Example 1. Put the 6mm green dough sheet into the compound calender 1 with a roller spacing of 3mm; put the 6mm yellow dough sheet into the composite calender 2 with a roller spacing of 3mm; put the 3mm green dough sheet on the 3mm yellow dough sheet and then After 8 continuous calendering, the roller spacing is 5mm, 4mm, 3.5mm, 2.5mm, 2mm, 1.5mm, 1.3mm, 1.1mm, and the final face thickness is 1mm, and the noodle width is 2.5mm.

[0086] Steam the prepared raw noodles in a steamer at 120°C for 2 minutes, take them out, cut them into sections and boil them in boiling water for 2min30s, take them out and soak them in distilled water at 10°C for 10s, ice water at 0°C for 50s, and 2% emulsifier solution at 0°C for 20s Finally, weigh 200g / per hole and put it into the mold;

[0087] Place the prepared noodles in a freezer at -30°C for 3 hours, and fre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com