Processing method of refrigerated apples with compound fragrance, anti-browning and preservation of hard and fresh slices

A processing method and anti-browning technology, which is applied in the direction of fruit and vegetable preservation, food preservation, and protection of fruits/vegetables with a coating protective layer, etc. It can solve the problems of insignificant preservation, single, and short storage time of fresh-cut apples, etc. problems, to achieve disinfection and antibacterial browning reaction, reduce substrate concentration, and improve storage quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

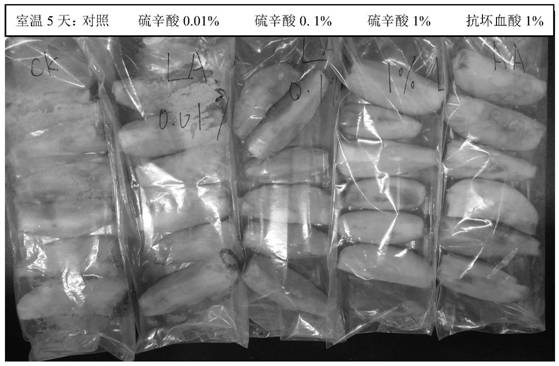

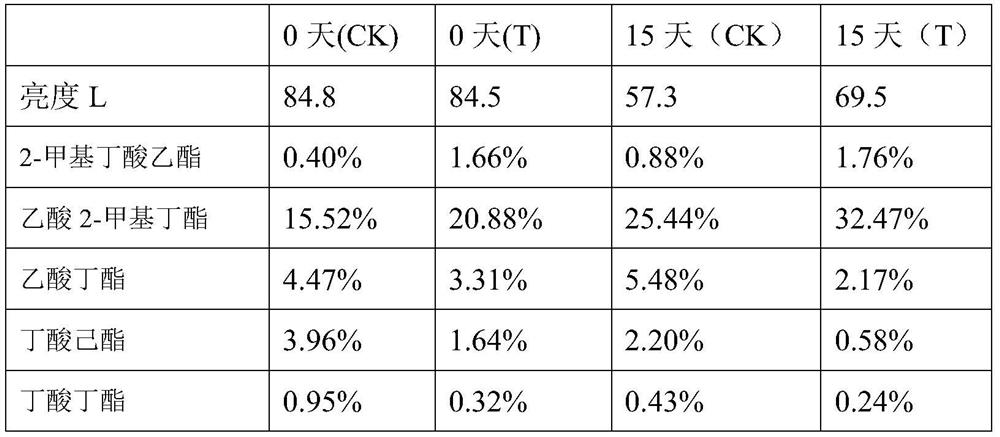

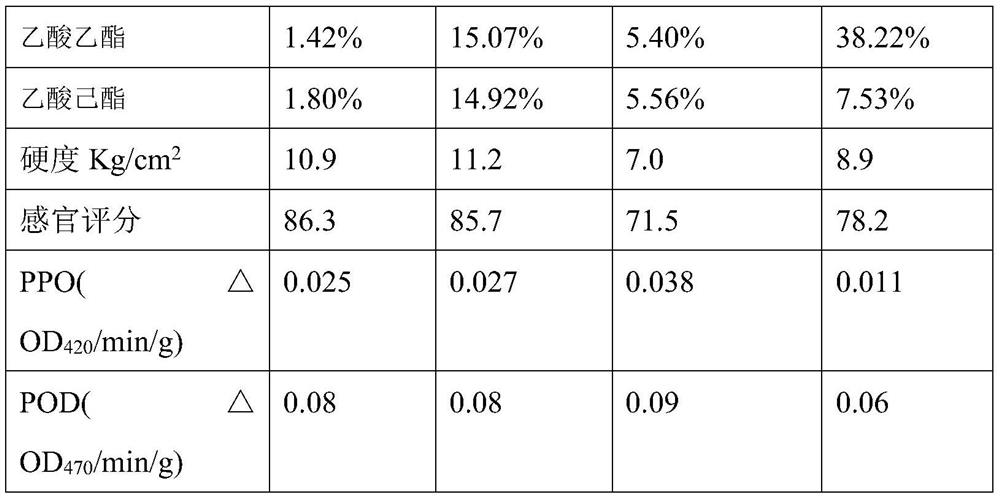

Image

Examples

Embodiment 1

[0037] A method for processing refrigerated apples with compound aroma, anti-browning, hard and fresh slices, the steps are as follows:

[0038] ⑴Material selection: select varieties that are not prone to browning, good fruits without damage by diseases and insect pests, such as Fuji apples, and use gradient cooling treatment before low-temperature air conditioning for 1-3 days to store at 0-0.5°C;

[0039] ⑵Aroma recovery pretreatment: For the loss of aroma of low-temperature controlled atmosphere apples, the whole fruit is placed in O 2 The concentration is 80-1000ml / l, the ethylene concentration is 0.5-100μl / l, and the rest is nitrogen in a controlled atmosphere device, and the continuous treatment is 12h-72h, and the temperature is gradually raised to 4-10℃ at the same time;

[0040] (3) Cleaning and disinfection: After washing the apples with water, soak them in 150-250 μL / L sodium hypochlorite solution for 2-10 minutes;

[0041] ⑷ Anti-browning cutting: In a mixed solut...

Embodiment 2

[0053] A method for processing refrigerated apples with compound aroma, anti-browning, hard and fresh slices, the steps are as follows:

[0054] ⑴Material selection: select varieties that are not prone to browning, good fruits without damage by diseases and insect pests, such as Fuji apples, and use gradient cooling treatment before low-temperature air conditioning for 1-3 days to store at 0-0.5°C;

[0055] ⑵Aroma recovery pretreatment: To solve the problem of low-temperature controlled atmosphere apple aroma loss, the whole fruit is placed in a controlled atmosphere device with an O2 concentration of 80-1000ml / l, an ethylene concentration of 0.5-100μl / l, and nitrogen before cutting. , continuous treatment for 12h-72h, while gradient temperature rise to 4-10℃;

[0056] (3) Cleaning and disinfection: After washing the apples with water, soak them in 150-250 μL / L sodium hypochlorite solution for 2-10 minutes;

[0057] ⑷ Anti-browning cutting: In a mixed solution of 300mg / L sodi...

Embodiment 3

[0069] A method for processing refrigerated apples with compound aroma, anti-browning, hard and fresh slices, the steps are as follows:

[0070] ⑴Material selection: select varieties that are not prone to browning, good fruits without damage by diseases and insect pests, such as Fuji apples, and use gradient cooling treatment before low-temperature air conditioning for 1-3 days to store at 0-0.5°C;

[0071] ⑵Aroma recovery pretreatment: To solve the problem of low-temperature controlled atmosphere apple aroma loss, the whole fruit is placed in a controlled atmosphere device with an O2 concentration of 80-1000ml / l, an ethylene concentration of 0.5-100μl / l, and nitrogen before cutting. , continuous treatment for 12h-72h, while gradient temperature rise to 4-10℃;

[0072] (3) Cleaning and disinfection: After washing the apples with water, soak them in 200 μL / L sodium hypochlorite solution for 5 minutes;

[0073] ⑷Anti-browning cutting: In a mixed solution of 200mg / L sodium chlor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com