Long-stroke quasi-zero-rigidity flexible guide mechanism

A flexible guide mechanism, quasi-zero stiffness technology, applied in the field of precision instruments and machinery, can solve problems such as the inability to guarantee a large stroke constant force output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention. It should be noted that, in the case of no conflict, the embodiments and the features in the embodiments of the present invention can be combined with each other, and the described embodiments are only some of the embodiments of the present invention, but not all of the embodiments.

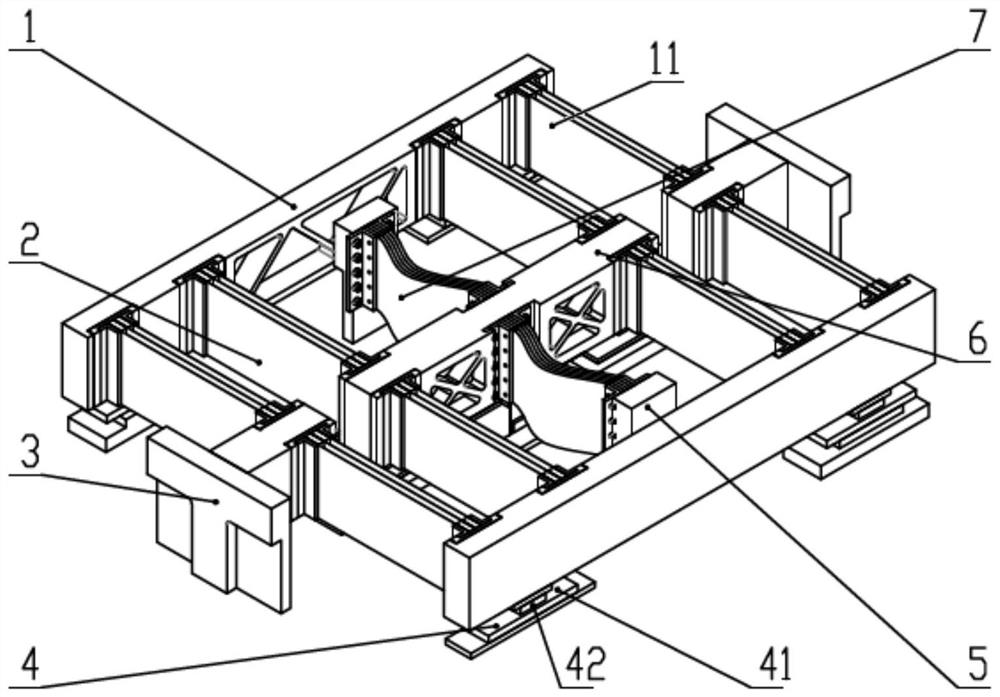

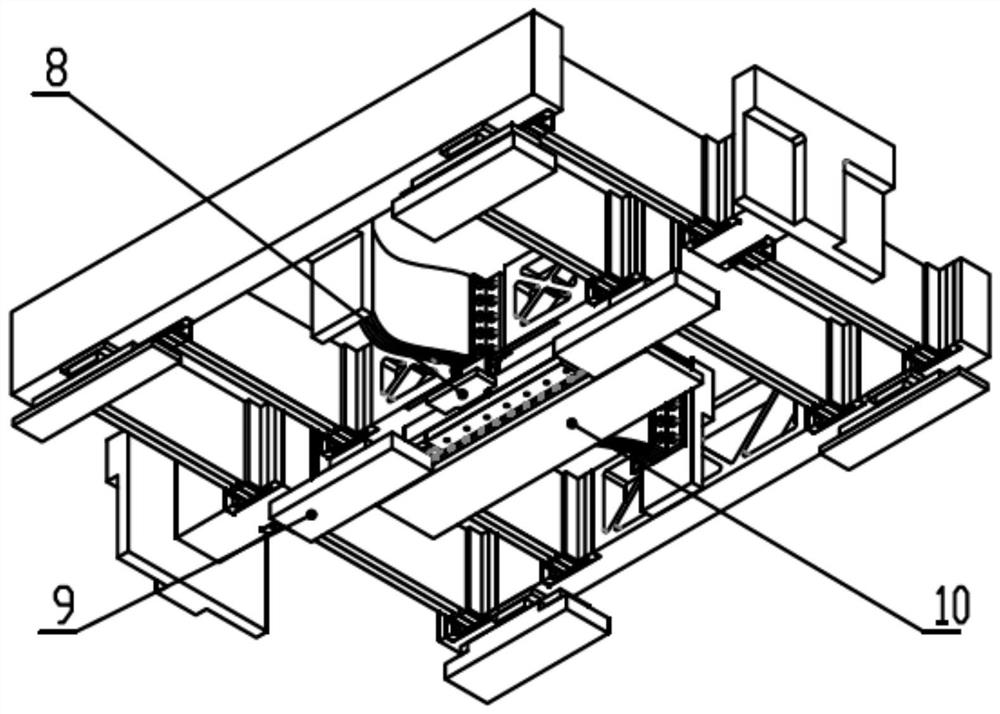

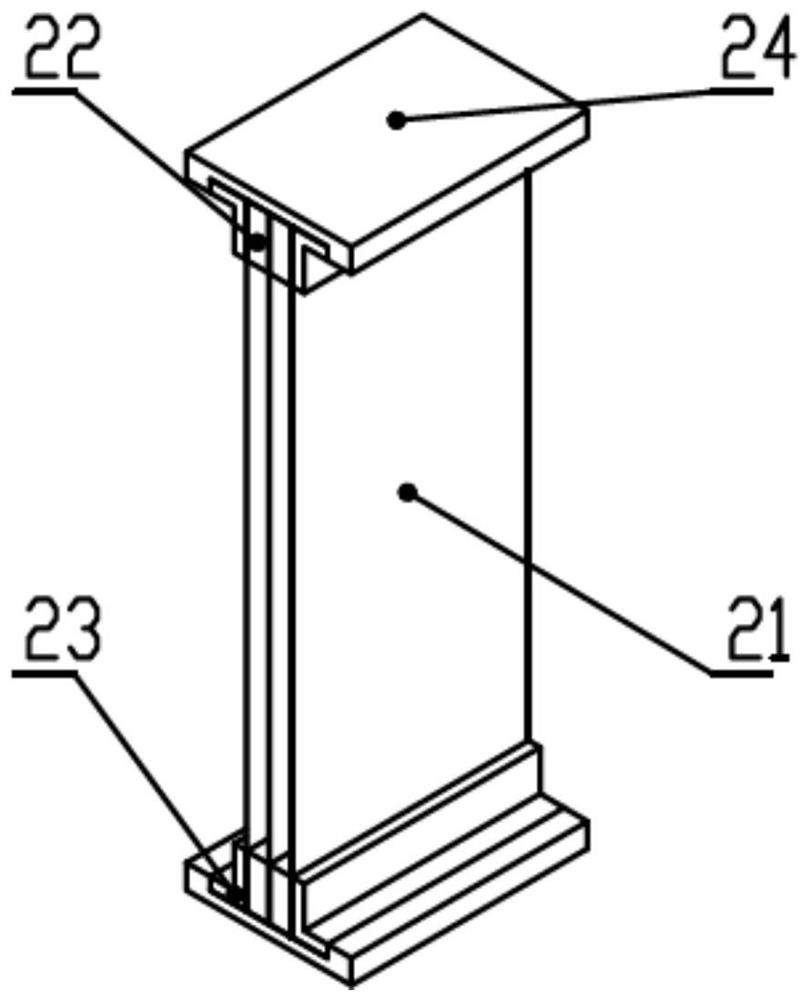

[0028] see Figure 1-5 Describe this embodiment, a long-stroke quasi-zero-stiffness flexible guide mechanism, which includes an indirect drive part 1, a direct drive part 6, a first positive stiffness reed assembly 2, a second positive stiffness reed assembly 11, and a negative stiffness reed The component 7 and the linear motor drive module 10, the left and right sides of the direct drive component 6 are respectively connected to the two indirect drive components 1 through two first positive stiffne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com