Back-swing electric servomotor device for water turbine

A technology of hydraulic turbines and servomotors, applied in safety devices, hydroelectric power generation, machines/engines, etc., can solve problems such as motion jamming, cumbersome maintenance, and large space occupation, and achieve high-precision linear motion, large range of motion, and space occupation small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

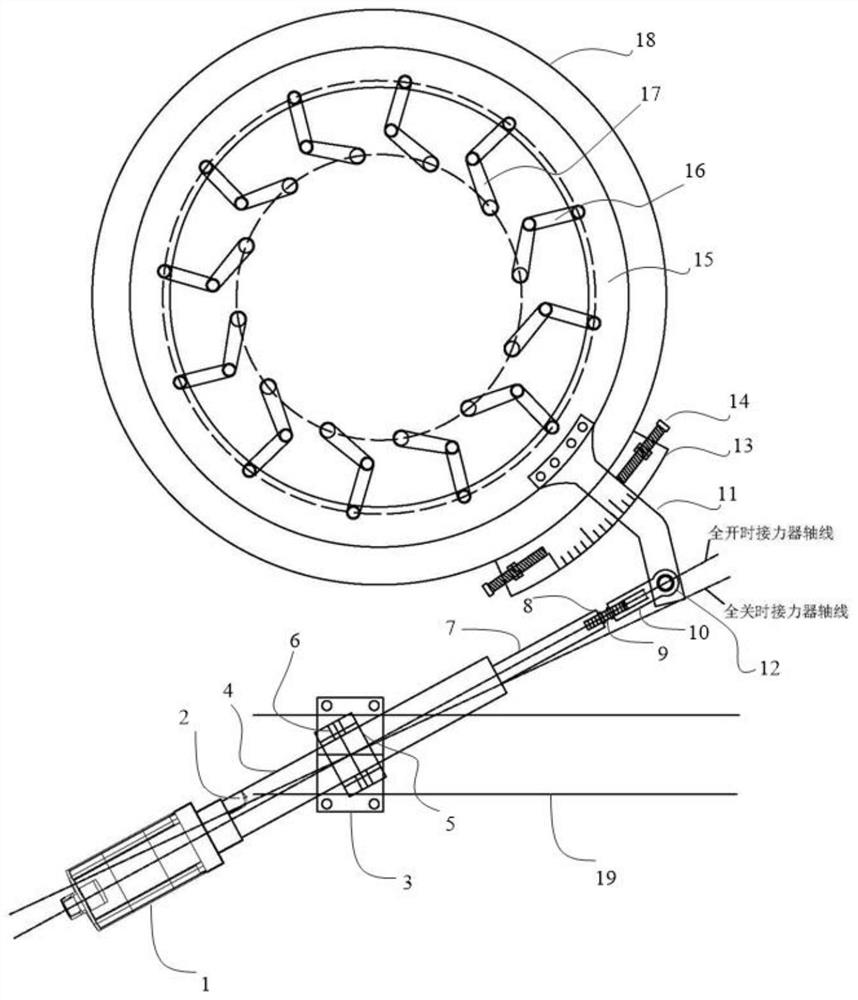

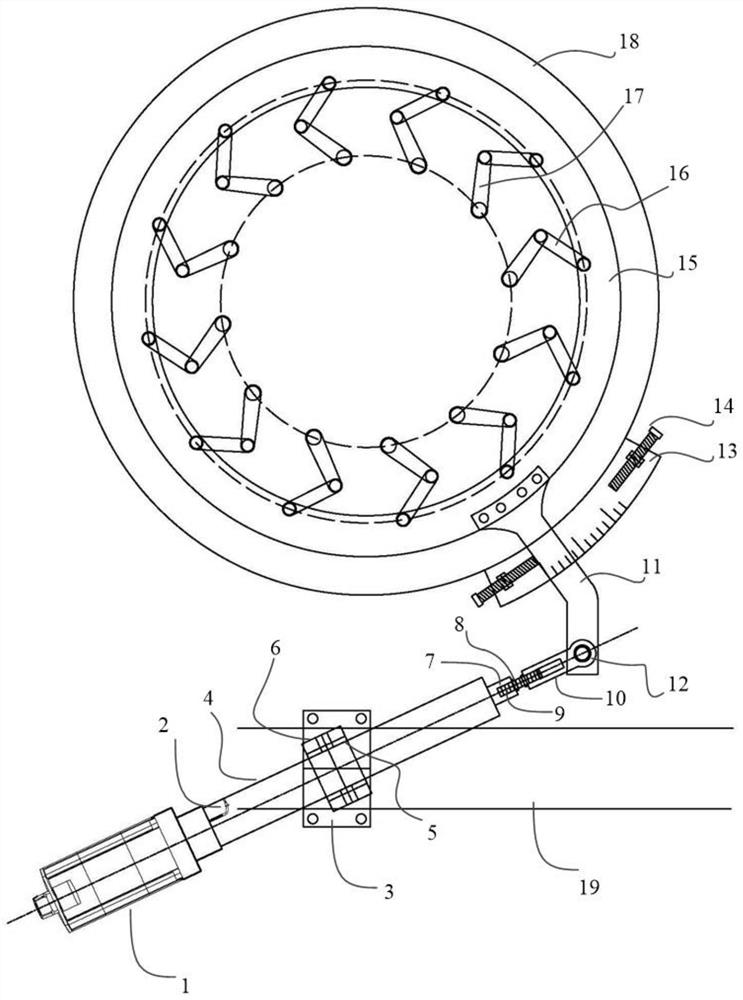

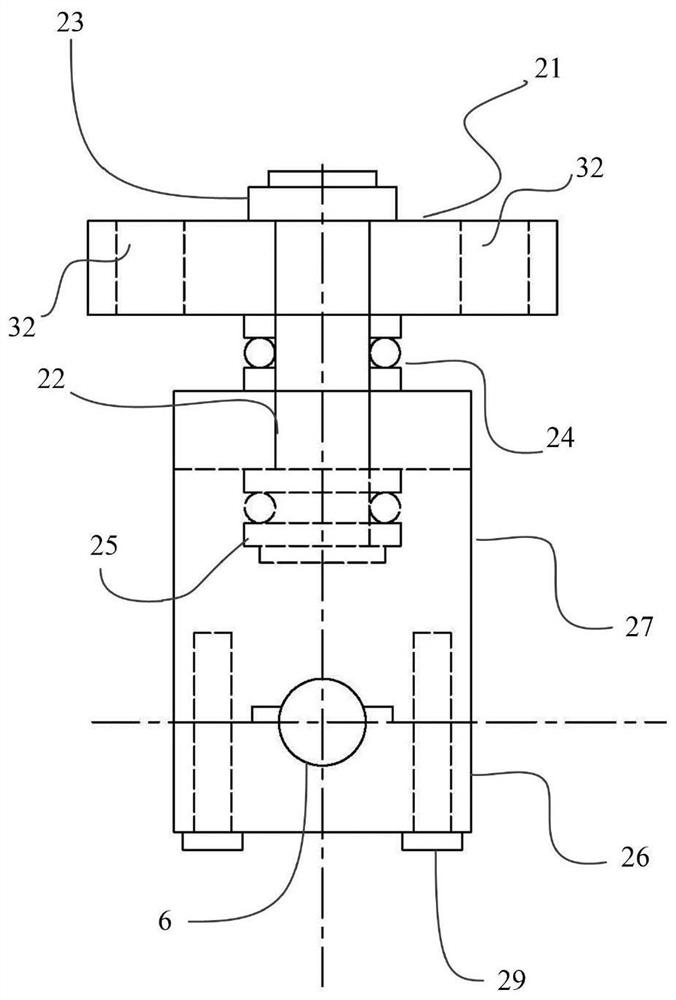

[0029] Such as figure 1 The shown rear-swing electric servomotor device for a water turbine is composed of a servo motor 1, an electric cylinder 4, a rotating base 3, a telescopic connecting rod, a guide sleeve 12, a linear displacement sensor 20 and a mechanical limit plate. Such as image 3 and Figure 4 As shown, the rotating base 3 includes a top plate 21, a vertical shaft 22, upper bearings 24 and 25, an upper support 27, and a lower support 26. The top plate 21 is fixed to the top cover of the water turbine by 4 bolts through the positioning screw holes 33 of the rotating base. Or on the water turbine layer platform 19, the upper support 27 and the lower support 26 clamp the trunnion 6 through the hexagon socket bolt 29, and the electric cylinder 4 is fixed on the rotating base 3, and the upper bearing 24 is placed on the uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com