Efficient metal plate cutting device for daily-use metal product production

A technology for metal products and cutting devices, applied in shearing devices, accessories of shearing machines, feeding devices, etc., can solve the problems of troublesome operation, time-consuming and laborious, slow cutting, etc., and achieves convenient operation, convenient use and fast cutting. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

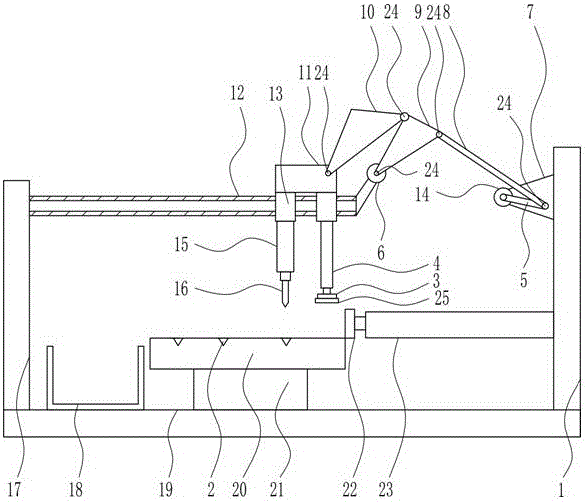

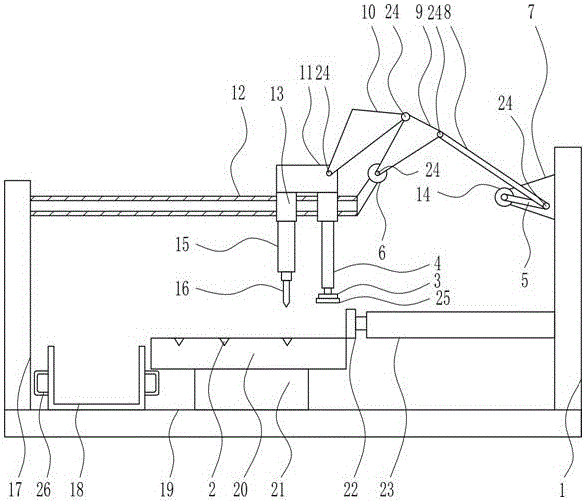

[0030] A high-efficiency metal sheet cutting device for the production of daily-use metal products, such as Figure 1-4As shown, it includes a right frame 1, a pressure block 3, a first electric push rod 4, a first connecting rod 5, a swing seat 6, a mounting seat 7, a second connecting rod 8, a first triangular plate 9, a second triangular plate 10, Fixed block 11, slide rail 12, slider 13, motor 14, cylinder 15, cutter 16, left frame 17, collection frame 18, bottom plate 19, cutting table 20, support rod 21, push plate 22, second electric push rod 23 and hinged parts 24, the left frame 17 is welded on the bottom plate 19 top, the left frame 17 right side upper part is connected with the slide rail 12 by the mode of bolt connection, the slide rail 12 front side sliding type is connected with the slide block 13, slide block 13 and slide block The rail 12 cooperates, the top of the slider 13 is connected to the fixed block 11 by bolt connection, the bottom of the left slider 13...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com