Wheel-track and swing arm consolidated barrier getting over mechanism

A wheel shoe and driving mechanism technology, applied in the direction of motor vehicles, transportation and packaging, etc., can solve the problems of unguaranteed maneuverability, large contact area, large friction force, etc., and achieve stable obstacle-crossing process, strong power, and improved The effect of obstacle clearance height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

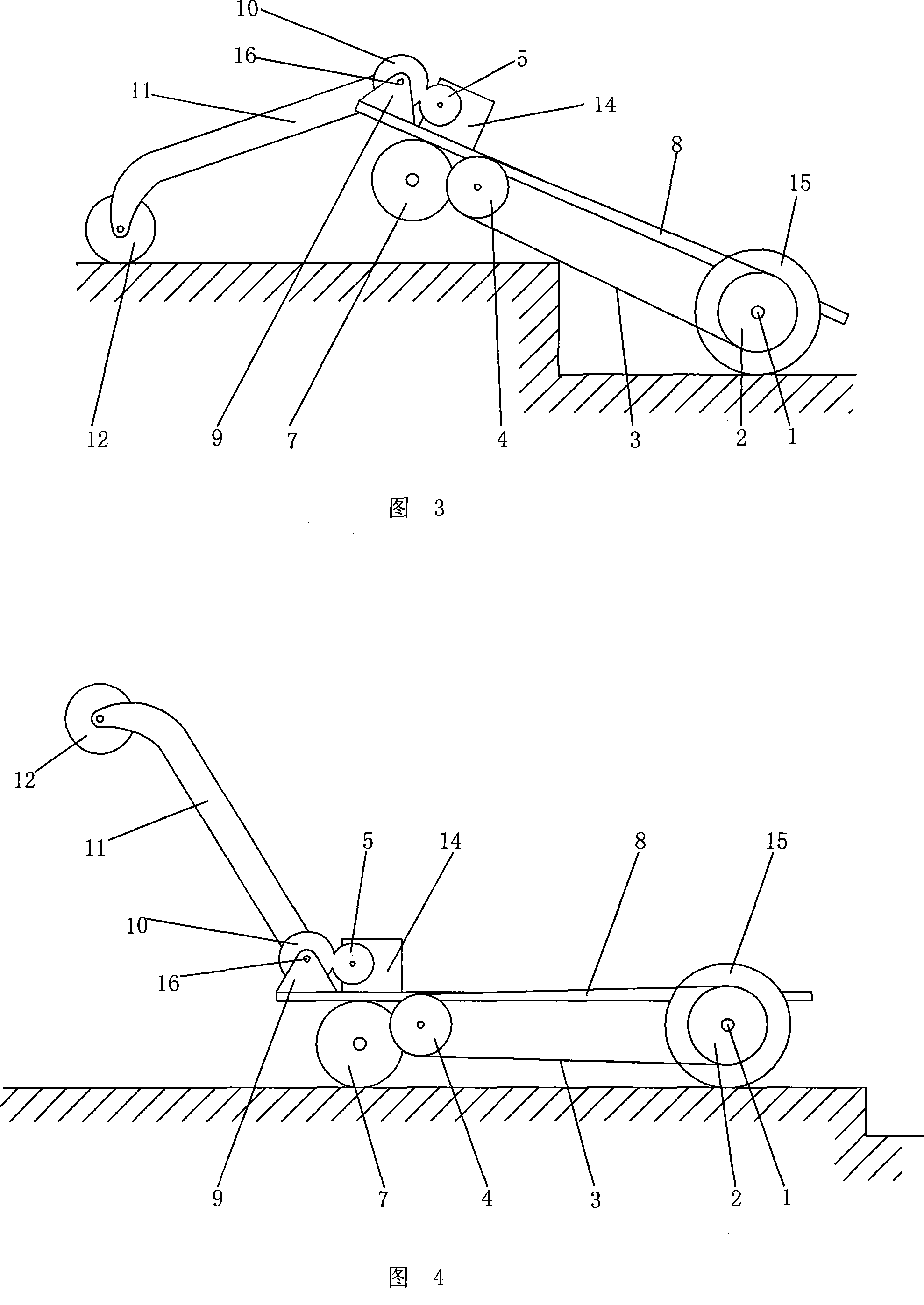

[0019] Figures 1 to 4 show that a specific embodiment of the present invention is: a combination of wheel shoes and swing arms for overcoming obstacles, including a vehicle frame 8, a guide wheel 7 in front of the lower part of the vehicle frame 8, and The rear wheel 15, the rear wheel shaft 1 is driven by a motor, and is characterized in that:

[0020] The bottom of the vehicle frame 8 is equipped with a wheel shoe transmission mechanism, which consists of: a front pulley 4 is installed in front of the bottom of the vehicle frame 8, and the lower edge of the front pulley 4 is higher than the lower edge of the guide wheel 7; The rear pulley 2 with a wheel diameter smaller than the rear wheel 15 is installed through the bearing, the front and rear pulleys 4, 2 are driven by the crawler belt 3, and the shaft of the front pulley 4 is driven by the obstacle-crossing drive mechanism 14;

[0021] The upper part of the vehicle frame 8 is equipped with a swing arm mechanism, which con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com