Cast-in-place canal one-time forming construction method of rolling type forming machine

A construction method and automatic forming machine technology, applied in water conservancy projects, artificial waterways, buildings, etc., can solve problems such as bleeding of concrete mixture, easy deposition, and impact on the compressive strength of water channels, so as to improve compressive strength and compactness High, easy pouring effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] The embodiment of the present application discloses a one-time forming construction method of a roll forming machine cast-in-place aqueduct, which includes the following steps:

[0049] Step 1. Measure the size of the site according to the design drawings, and mark the specific excavation position of the water channel on site according to the design requirements.

[0050] Step 2. Excavate the water channel trench according to the actual position marked in step 1.

[0051] Step 3, prepare concrete mixture, specifically as follows:

[0052] Step 3-1, add 440kg of cement, 100kg of sand, 100kg of slag, 120kg of volcanic rock powder, 50kg of nano-silica and 70kg of half the mass of water into the concrete mixer, stir at a speed of 150r / min, and mix evenly to form cement slurry.

[0053] In step 3-2, continue to add 15kg of konjac powder, 30kg of water glass and 70kg of remaining water to the cement slurry while stirring, and stir and mix evenly to obtain the concrete mixtu...

Embodiment 2-3

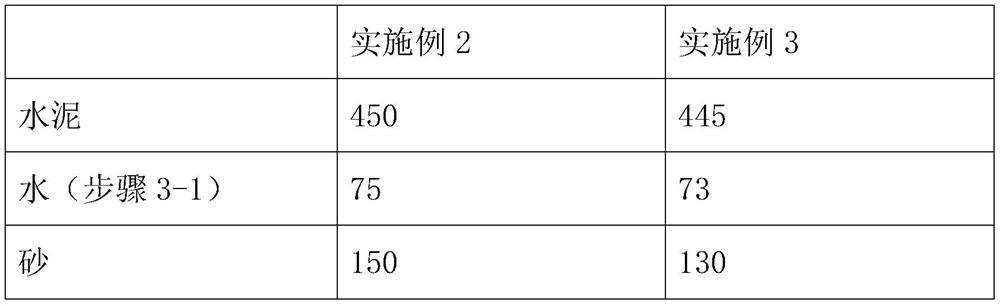

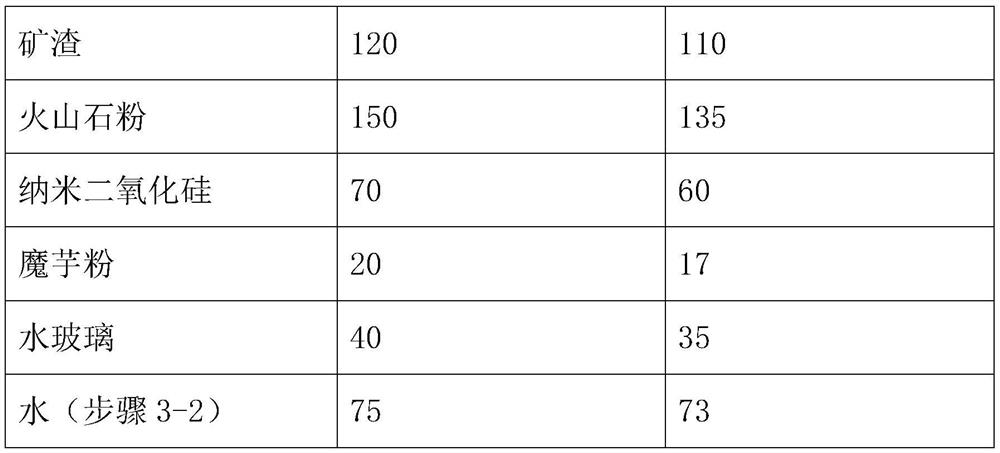

[0056] The difference from Example 1 is that the amount of each component of the concrete mixture is different, and the specific amount of each component is shown in Table 2.

[0057] And the curing temperature in Example 2 is 35° C., and the curing time is 30 days; the curing temperature in Example 3 is 40° C., and the curing time is 28 days.

[0058] Table 2

[0059]

[0060]

Embodiment 4

[0062] The difference from Example 3 is that 0.4 kg of thickener is added in step 3-2, and the thickener in this example is prepared by uniformly mixing dextrin and hydroxyethyl cellulose at a mass ratio of 1:4. become.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com