Improved MVR (mechanical vapor recompression) device applied to zero discharge of catalyst regeneration wastewater

An improved technology for recycling wastewater, applied in chemical instruments and methods, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc. and other problems, to achieve good heat transfer efficiency, reduce heating energy consumption, and save land.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the examples. The description of the following examples is provided only to aid the understanding of the present invention. It should be pointed out that for those skilled in the art, without departing from the principle of the present invention, some improvements and modifications can be made to the present invention, and these improvements and modifications also fall within the protection scope of the claims of the present invention.

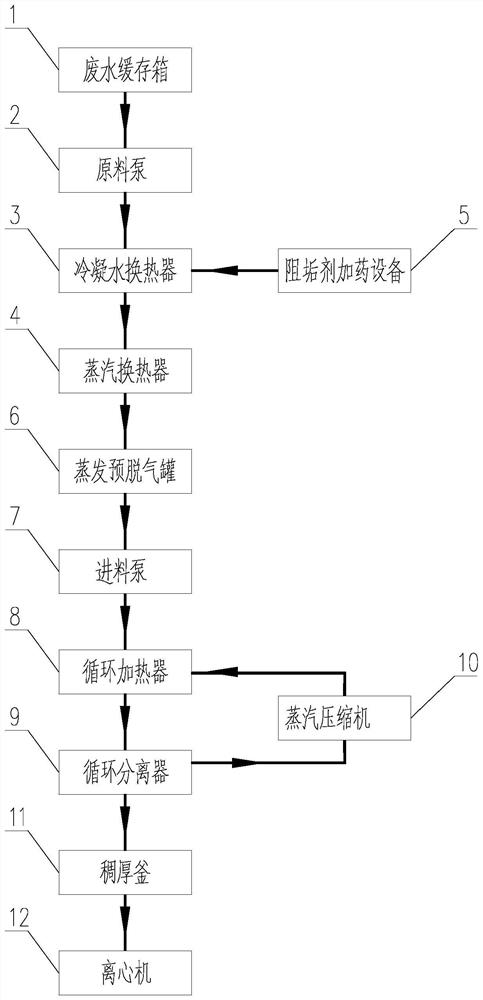

[0025] Such as figure 1 As shown, as an example, this improved MVR device applied to zero discharge of catalyst regeneration wastewater includes a water inlet and a water outlet, and there are sequentially between the water inlet and the water outlet from upstream to downstream: 1 waste water buffer tank , 2 Raw material pump, 3 Condensed water heat exchanger, 4 Steam heat exchanger, 5 Antiscalant dosing equipment, 6 Evaporation pre-degassing tank, 7 Feed pump, 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com