Processing technology of aluminum-plastic packaging bag

A processing technology, aluminum-plastic packaging film technology, applied in the field of aluminum-plastic food packaging bags, can solve the problems of aluminum-plastic food packaging bags lack of softness, easy to fold and break at the tear, and inconvenient tearing at the tear, so as to improve the use Improvement of safety, scope of use, and effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

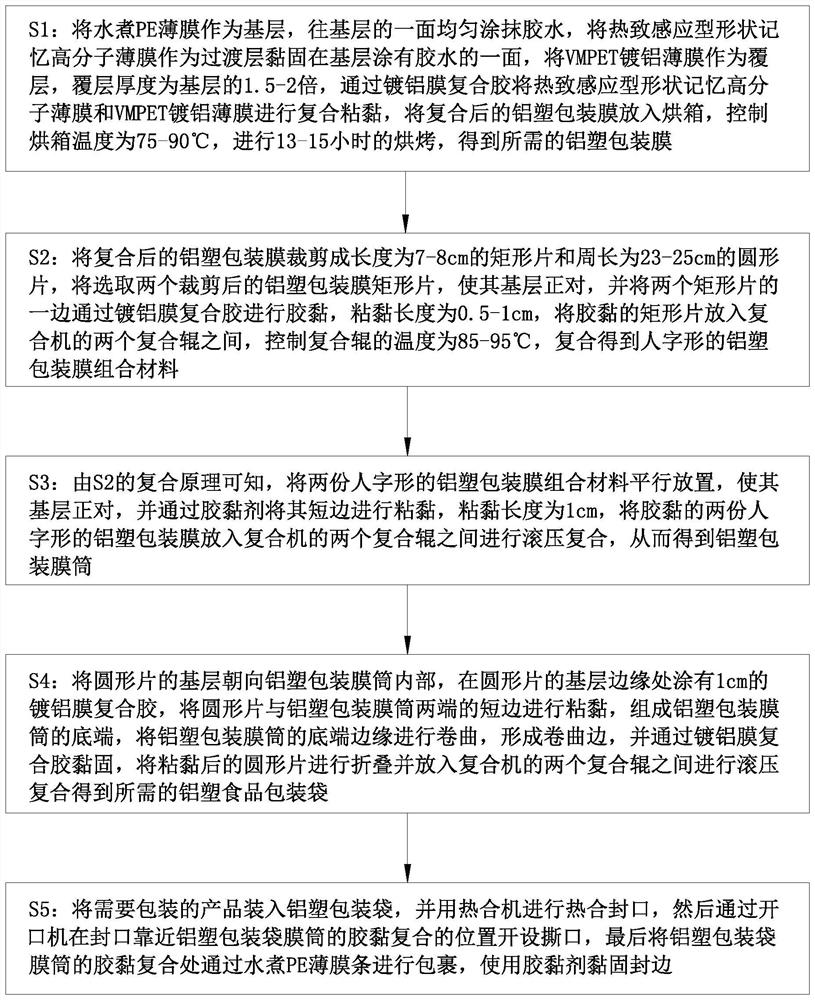

Method used

Image

Examples

Embodiment approach

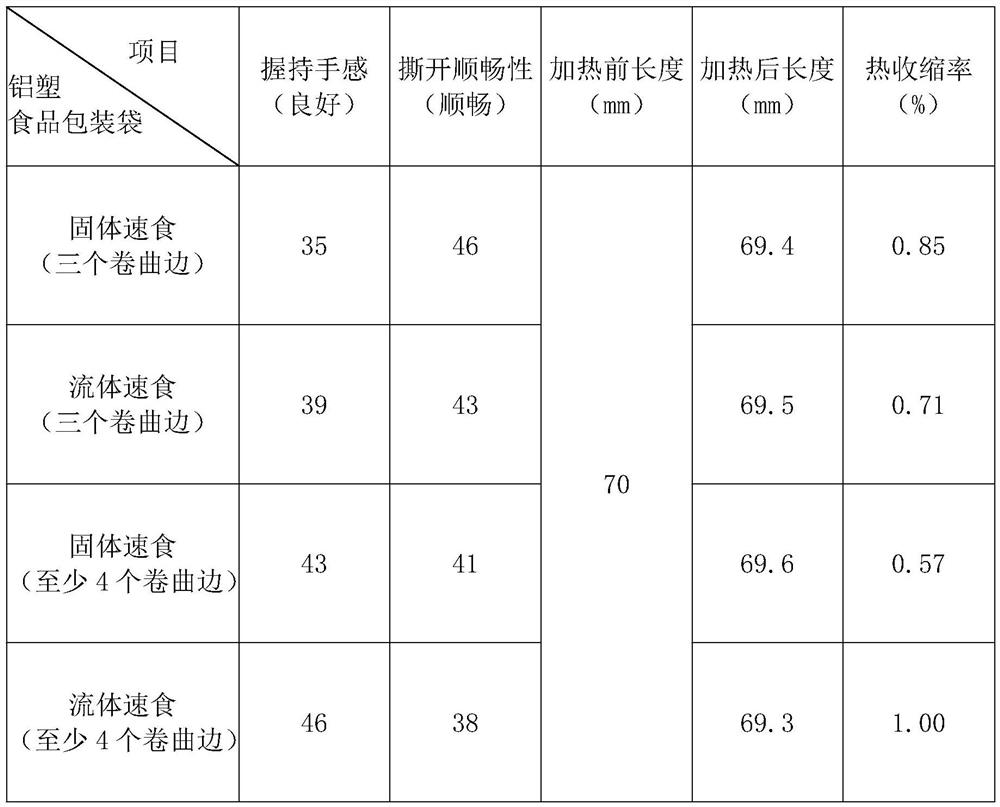

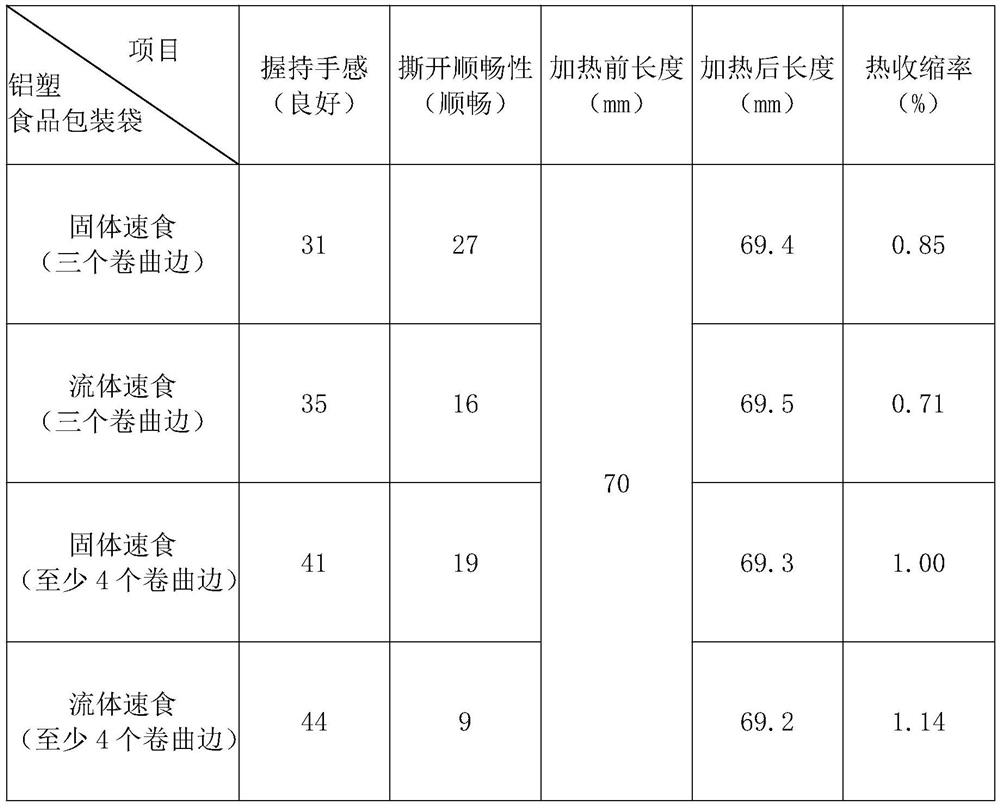

[0043] As an embodiment of the present invention, when the number of curled sides of the aluminum-plastic food packaging bag is three; The distance between two metal wires is 7cm. When S2 cuts along the parallel direction of the metal wires, it cuts at 1.25cm from the upper end of the metal wires; When in use, when there is no environment around the user where the aluminum-plastic food packaging bag can be placed horizontally, and the food can only be eaten by hand, first stretch the curled edge of the aluminum-plastic food packaging bag , then hold the bottom layer of the aluminum-plastic food packaging bag upwards, and pull the metal wire outward, so that the metal wire drives the aluminum-plastic food packaging bag attached to it to tear along the tear mark, so that the bottom layer of the aluminum-plastic food packaging bag opens. Thereby providing the user with another way of eating, which is convenient for the user to eat the instant food in the aluminum-plastic food pac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com