Automatic splicing, glue injecting and fixing equipment for automobile solid wood floors

A technology for solid wood flooring and automatic splicing, which is used in the joining of wooden veneers, wood processing appliances, and adhesive application devices. The effect of excessive glue filling, avoiding waste of resources and reducing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

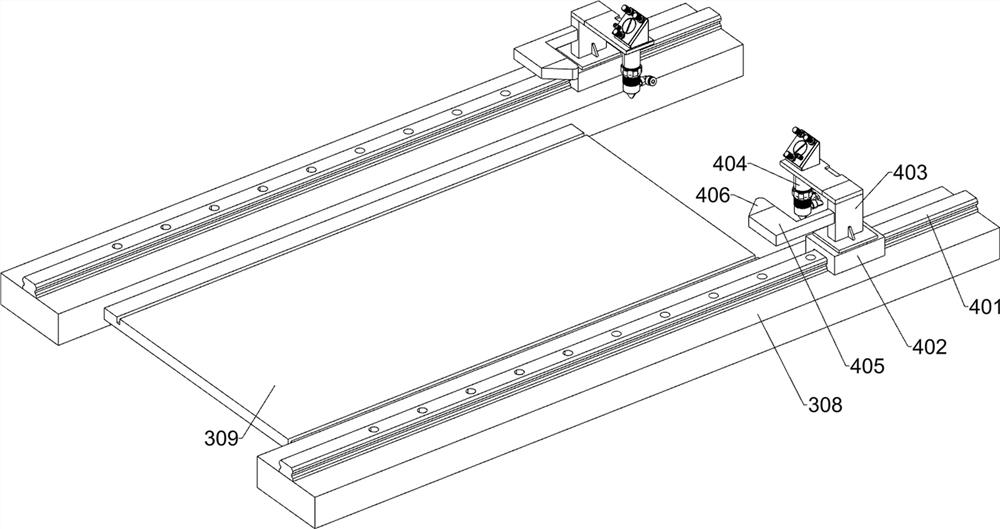

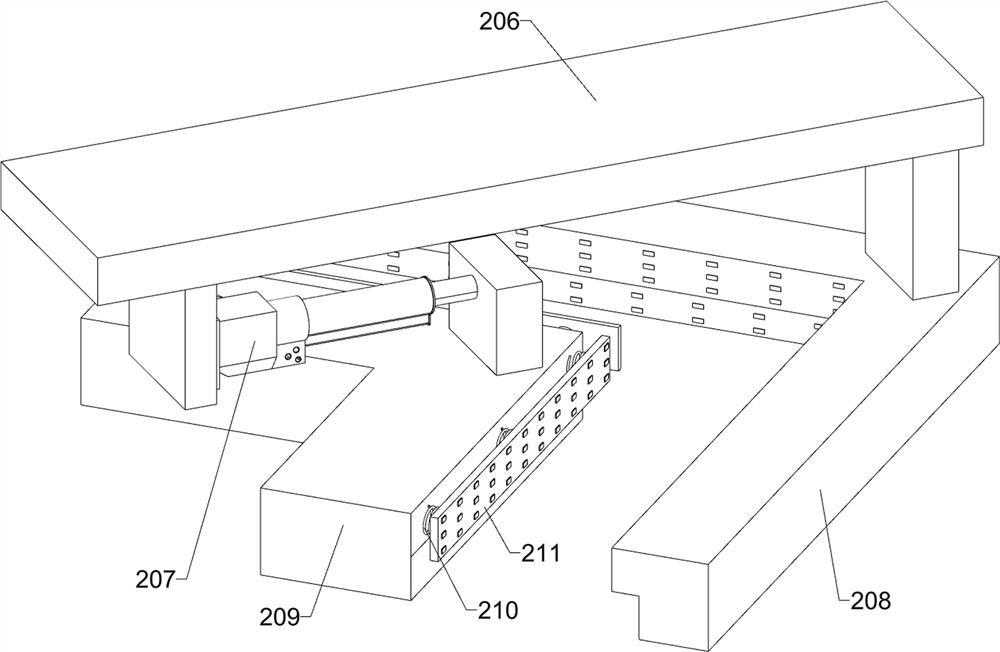

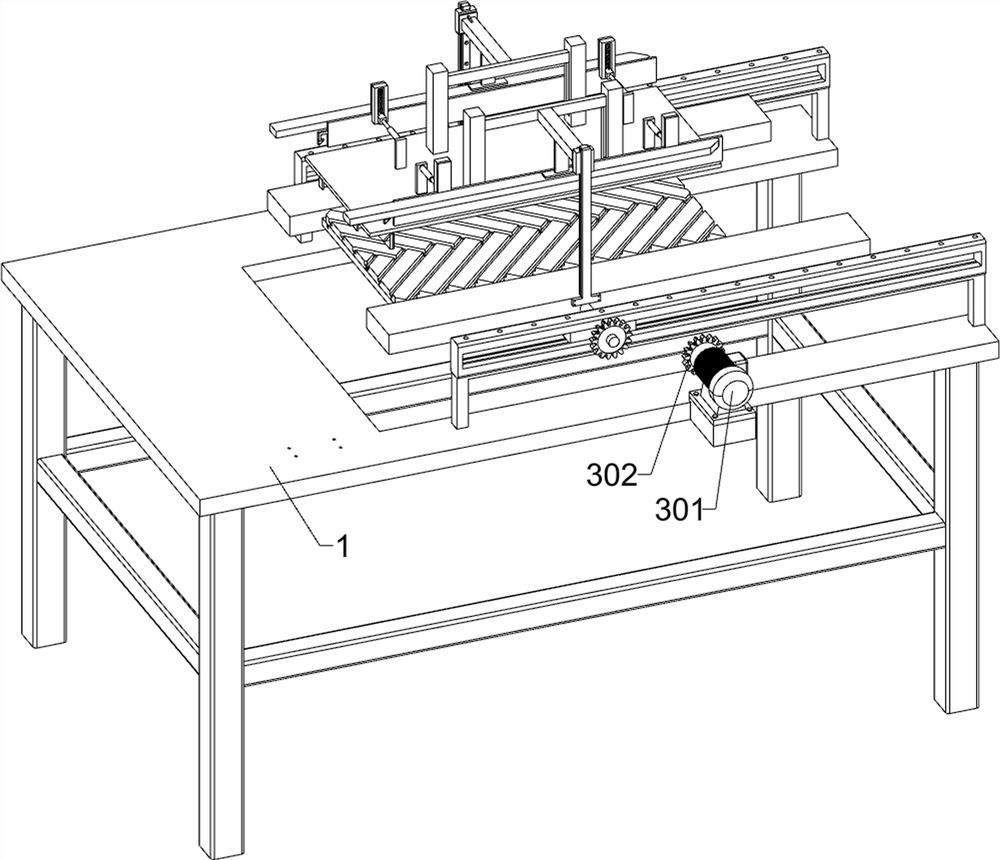

[0032] An automatic splicing glue injection fixing device for solid wood floors of automobiles, such as Figure 1-11 As shown, it includes chassis 1, conveying assembly, clamping assembly, sealing assembly and cutting assembly; the conveying assembly is installed on the left side of the upper side of the chassis 1; the clamping assembly is installed on the left side of the upper side of the chassis 1; the clamping assembly Located on the right side of the conveying assembly; a sealing assembly is installed on the upper side of the chassis 1; a cutting assembly is installed at the front and rear of the sealing assembly.

[0033] The conveying assembly includes a first fixed plate 101, a support plate 102, a first support frame 104, a second elastic telescopic rod 114, a V-shaped plate 115, a V-shaped receiving plate 116, a second wedge block 117 and a conveying unit; the chassis 1 A first fixed plate 101 is fixedly connected to the front side of the left part and the rear side ...

Embodiment 2

[0045] On the basis of Example 1, such as Figure 12 As shown, it also includes a glue injection assembly and a gantry 2; the upper left part of the bottom frame 1 is fixedly connected with the gantry 2; the upper part of the gantry 2 is installed with a glue injection assembly; the glue injection assembly includes a sixth fixing plate 501, Seventh fixed plate 502, third electric push rod 503, rubber delivery tube 504, electric rubber outlet head 505 and rubber guide tube 506; the sixth fixed plate 501 is fixed on the upper right side of the gantry frame 2; the sixth fixed plate 501 is fixed on the right side There is a seventh fixed plate 502; a third electric push rod 503 is fixedly connected to the lower front part and the lower rear part of the seventh fixed plate 502 respectively; Rubber hose 504; the upper part of the rubber hose 504 is fixed with two rubber guide tubes 506; the rubber guide tube 506 is connected with the rubber delivery tube 504; connected.

[0046] I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com