Mannheim process potassium sulfate tail gas treatment system

A technology for tail gas treatment and potassium sulfate, which is applied in waste heat treatment, separation methods, chemical instruments and methods, etc., can solve the problems of low tail gas treatment efficiency and no comprehensive treatment of three kinds of tail gas, so as to improve comprehensive treatment efficiency and simple structure , the effect of preventing high temperature aging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

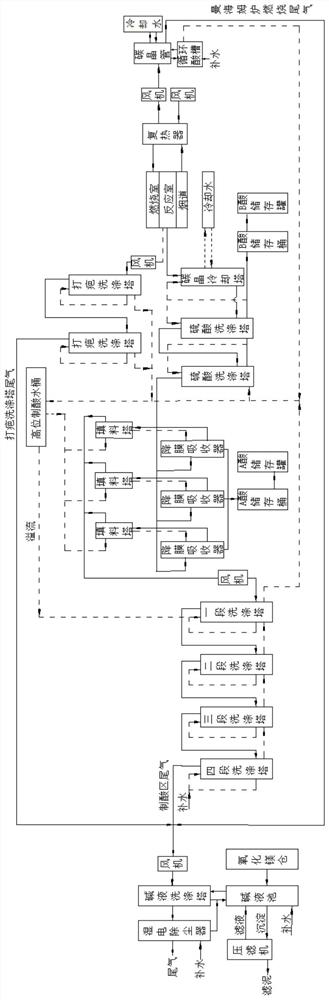

[0039] Such as Figure 1-2As shown, the Mannheim method potassium sulfate tail gas treatment system of the present invention includes a Mannheim furnace tail gas generation part, a combustion tail gas cooling and cooling part, a hydrogen chloride gas washing part, a tail gas conveying part and a combustion tail gas washing part.

[0040] Mannheim furnace tail gas generation part:

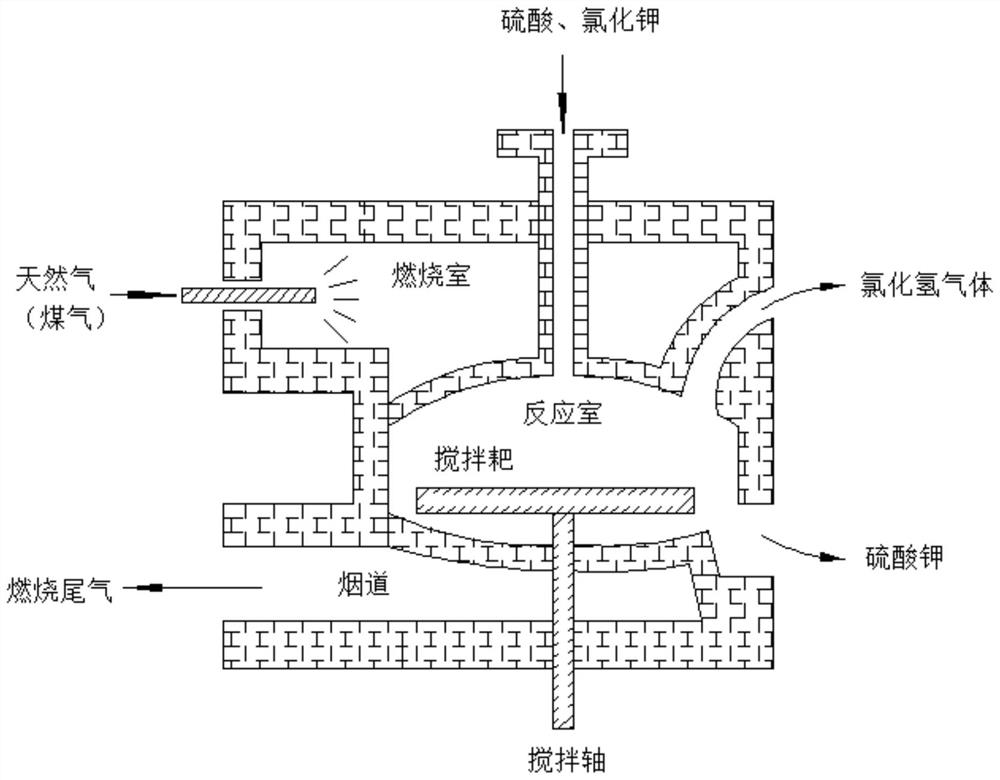

[0041] This part includes the Mannheim furnace. The upper part of the Mannheim furnace is a combustion chamber, the middle part is a reaction chamber, and the lower part is a flue. During the production of potassium sulfate, the tail gas is discharged through the flue, and the hydrogen chloride gas generated is discharged through the reaction chamber. .

[0042] Specifically, the basic structure of the Mannheim furnace is as follows figure 2 As shown, the upper part is the combustion chamber, the middle part is the reaction chamber, and the lower part is the flue, wherein the combustion chamber an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com