Autolysis type strong self-adhesive elastic bandage and preparation method thereof

A self-adhesive elastic bandage and elastic bandage technology, applied in the field of bandages, can solve the problems of mildew and allergies to natural latex adhesives, and achieve the effects of reducing nitrogen content, avoiding allergies, and reducing protein content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

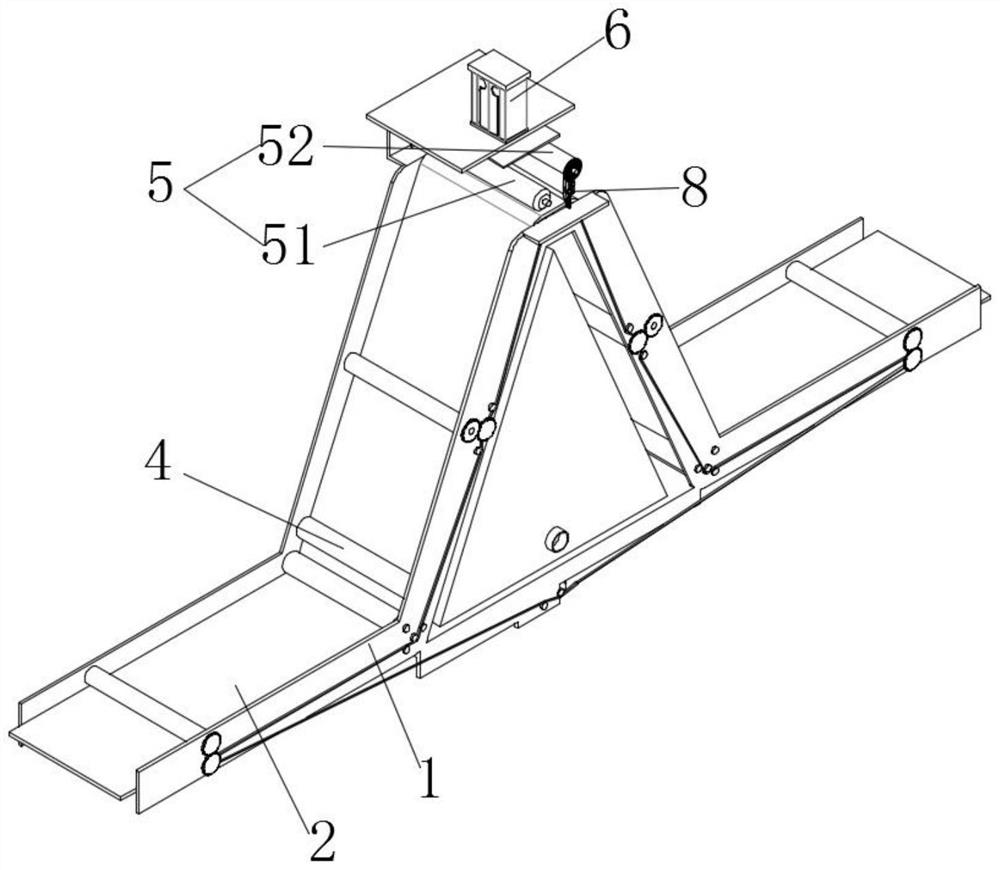

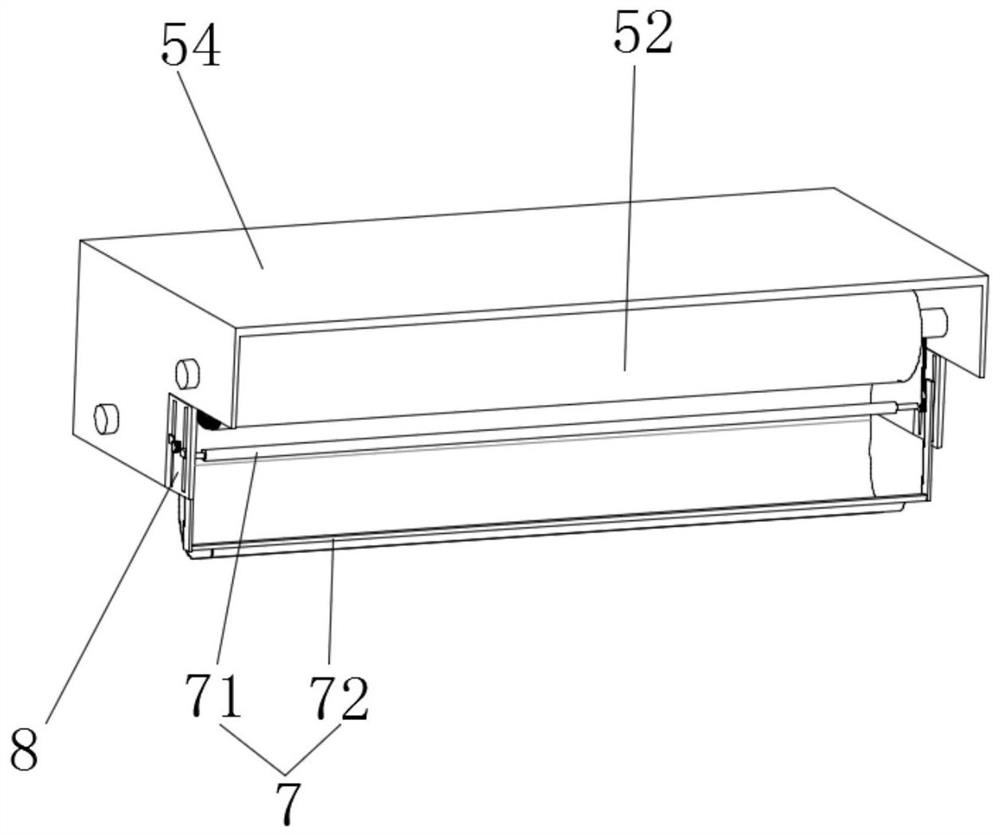

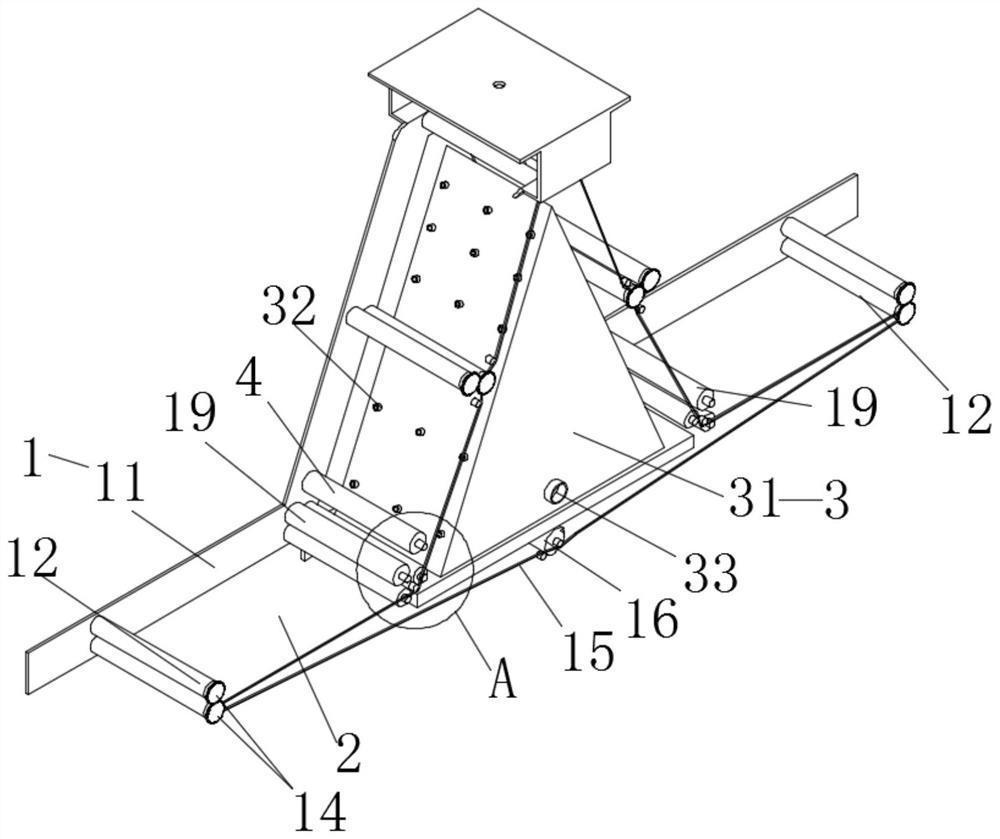

Image

Examples

Embodiment 1

[0052] (1) Mix N,N-dimethylformamide, graphene oxide, potassium fluoride, potassium iodide, and epichlorohydrin with a mass ratio of 1200:1:450:60:250 evenly, and react at 80°C for 12 hours, After the reaction, first centrifuge, then wash, after washing, dry to obtain epoxidized graphene; then epoxidized graphene and natural latex are mixed uniformly according to the mass ratio of 1:50, and sodium hydroxide is added to adjust the pH to 8, At 20 °C for 3 hours, after the reaction, centrifuge first, and then rotary steam to obtain graphene-modified natural latex; The mass ratio is 200:1 and the mixture is uniform to obtain the graphene modified natural latex adhesive;

[0053] (2) Mixing N,N-dimethylformamide, graphene oxide, and γ-methacryloyloxypropyltrimethoxysilane with a mass ratio of 80:1:2 uniformly, and reacting, after the reaction, First filter, then wash, and after washing, dry to obtain alkenyl-modified graphene; then stir and mix distilled water, chitosan, polyethyl...

Embodiment 2

[0056] (1) Mix N,N-dimethylformamide, graphene oxide, potassium fluoride, potassium iodide, and epichlorohydrin with a mass ratio of 4000:3:1200:240:800 evenly, and react at 95°C for 15h, After the reaction, first centrifuge, then wash, and after washing, dry to obtain epoxidized graphene; then epoxidized graphene and natural latex are mixed uniformly according to the mass ratio of 1:40, and sodium hydroxide is added to adjust the pH to 9, A reaction occurs, after the reaction, centrifugation first, and then rotary evaporation to obtain a graphene-modified natural latex; the graphene-modified natural latex with a mass ratio of 100:1 and an antioxidant 2,6-di-tert-butyl-p-cresol are mixed Evenly, graphene modified natural latex adhesive is obtained;

[0057] (2) Mixing N,N-dimethylformamide, graphene oxide, and γ-methacryloyloxypropyltrimethoxysilane with a mass ratio of 800:9:20 uniformly and reacting, after the reaction, First filter, then wash, and after washing, dry to obt...

Embodiment 3

[0060] (1) Mix N,N-dimethylformamide, graphene oxide, potassium fluoride, potassium iodide, and epichlorohydrin with a mass ratio of 1200:1:400:64:280 evenly, and react at 105°C for 18h, After the reaction, first centrifuge, then wash, and after washing, dry to obtain epoxidized graphene; then epoxidized graphene and natural latex are mixed uniformly according to the mass ratio of 1:40, and sodium hydroxide is added to adjust the pH to 9, A reaction occurs, after the reaction, first centrifugation, and then rotary evaporation to obtain a graphene-modified natural latex; the graphene-modified natural latex with a mass ratio of 50:1, an antioxidant 2-2-4 trimethyl-1-2 -The dihydroquinoline polymer is evenly mixed to obtain a graphene-modified natural latex adhesive;

[0061] (2) N,N-dimethylformamide, graphene oxide, and γ-methacryloyloxypropyltrimethoxysilane with a mass ratio of 200:2:5 were mixed uniformly, and reacted. After the reaction, First filter, then wash, and after ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com