Outer rotor structure of brushless motor and surface treatment method thereof

A brushless motor and surface treatment technology, applied in chemical instruments and methods, manufacturing stator/rotor body, magnetic circuit shape/style/structure, etc., can solve problems such as poor stability, poor motion stability, and large structural imbalance. Achieve the effect of reducing the difficulty of assembly and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

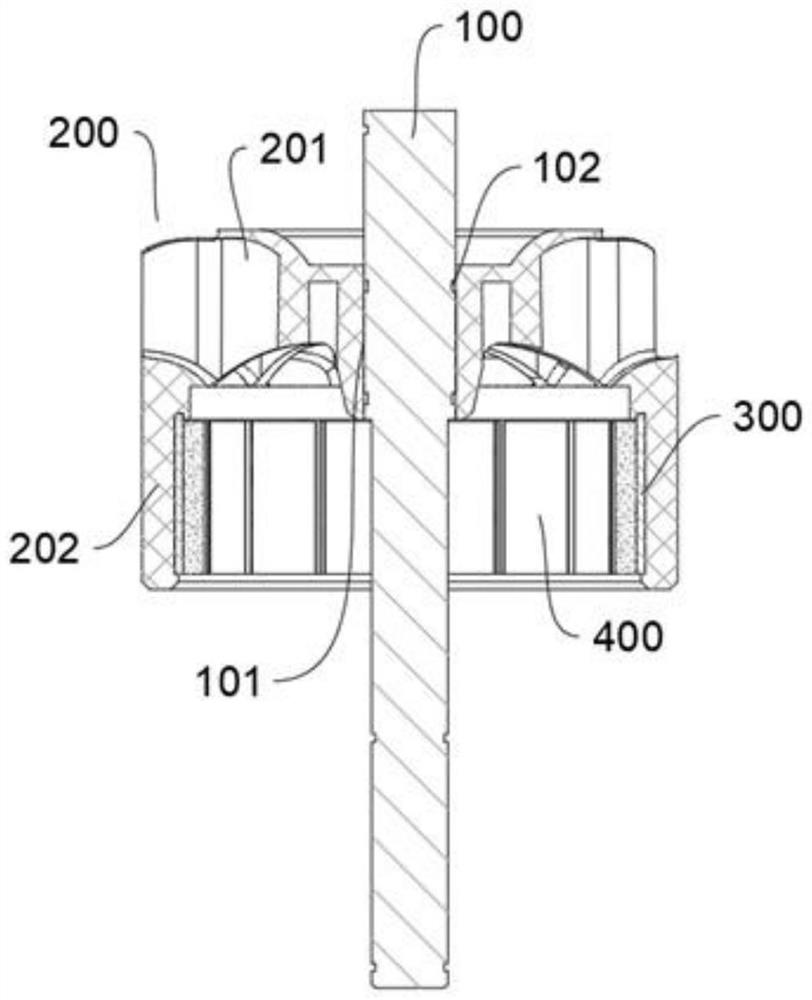

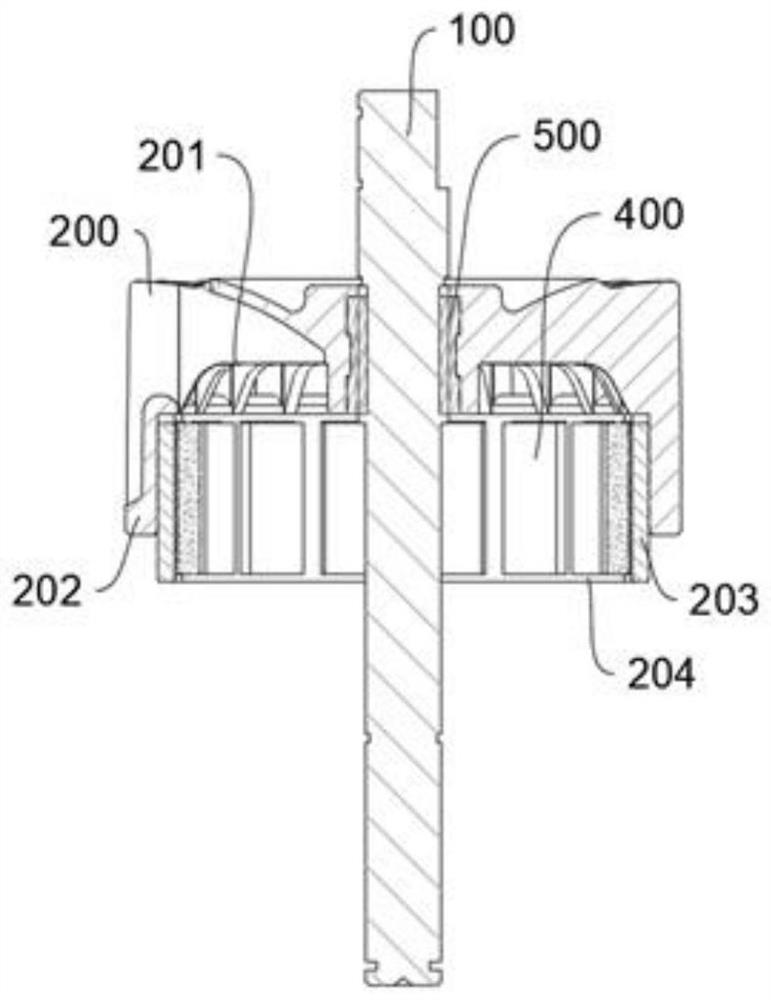

[0060] a kind of like figure 1 The outer rotor structure of the brushless motor shown specifically includes:

[0061] Rotor shaft 100, impeller 200 and magnetic structure;

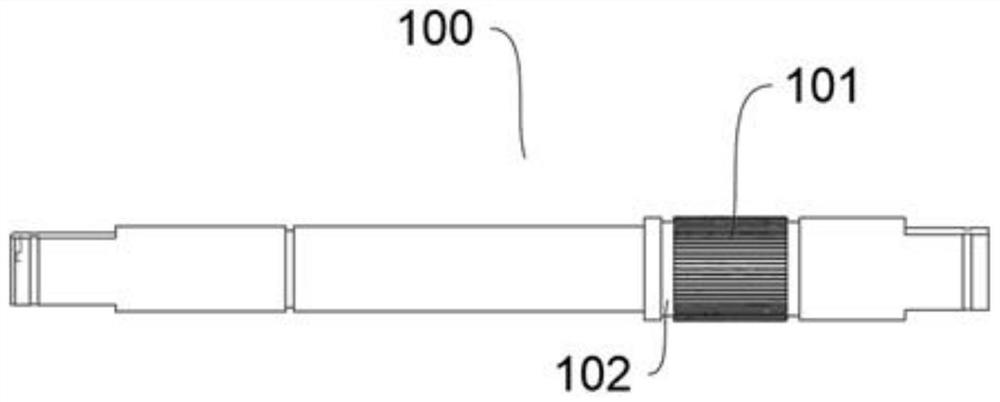

[0062] The impeller 200 is sleeved on the rotor shaft 100, and the rotor shaft 100 is provided with an anti-slip structure relative to the place where the impeller 200 is sleeved;

[0063] The anti-slip structure specifically includes a radial anti-slip structure that prevents the impeller 200 from slipping in the circumferential direction relative to the rotor shaft 100, and an axial anti-slip structure that prevents the impeller 200 from slipping axially relative to the rotor shaft 100;

[0064] Specific as image 3 shown;

[0065] The radial anti-slip structure includes, but is not limited to, conventional anti-slip structures such as knurling or damping treatment on the outer surface to form a damping layer or snap fit and fixation, but for the present invention, this embodiment adopts a relatively ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com