System and method for manufacturing special-shaped three-dimensional battery cell

A manufacturing method and cell technology, applied in the manufacture of secondary batteries, electrode carriers/collectors, circuits, etc., can solve the problems of more and more personalized requirements, and achieve safe operation, process-based high-precision, The effect of improving the yield rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to better illustrate the purpose, technical solutions and advantages of the present invention, the specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are used to illustrate the present invention, but not to limit the scope of the present invention.

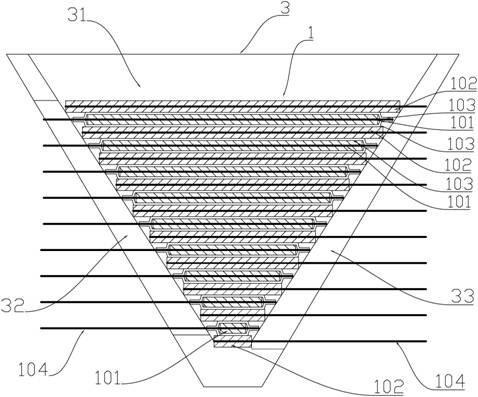

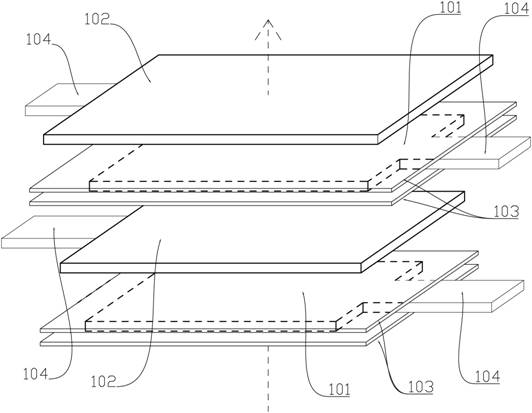

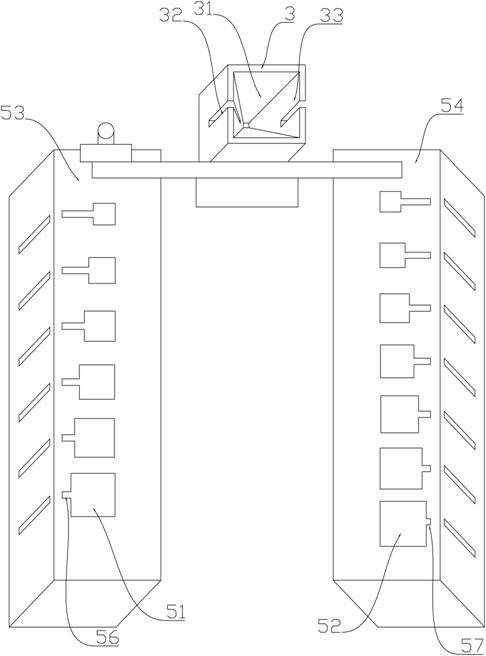

[0039] as attached Figures 1 to 2 As shown, the battery cell production system and method in the present invention can be produced as an example, and can be used at least to produce a battery cell 1 whose profile increases from one end to the other. Sheets and separators 103 are stacked alternately to form cells 1 of special-shaped rectangular pyramids, or other special-shaped cells 1 of multiple corrugated cones, trapezoidal shapes, hemispherical shapes, semi-ellipsoids, and the above-mentioned three-dimensional shapes.

[0040] as attached Figures 1 to 4 As shown, it can embody th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com