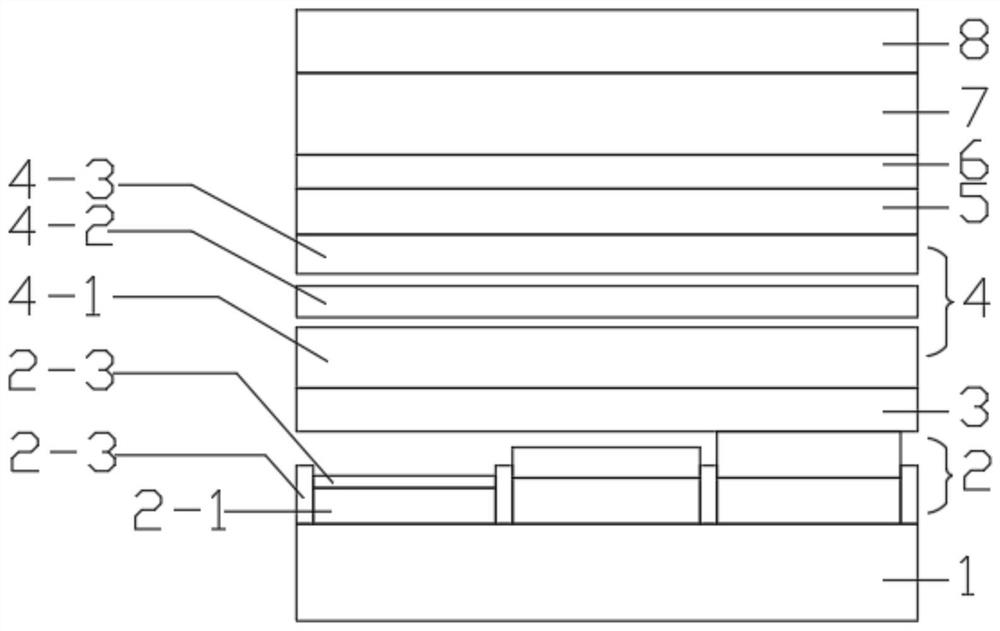

Full-color display structure of silicon-based OLED (Organic Light Emitting Diode) micro display

A technology of microdisplay and full-color display, which is applied in the manufacture of electric solid-state devices, semiconductor devices, and semiconductor/solid-state devices, etc., and can solve the problem of large loss of sub-pixel brightness, low color gamut of full-color display, and color purity of monochromatic light. Low problems, to achieve the effect of reduced color film process flow, large display color gamut, and high color purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Example 1: Taking the green sub-pixel as an example, the transparent conductive layer is made of ITO material with a thickness of 100-200 Å, and the thickness of the transparent conductive layer is adjusted so that the microcavity effect of the blue sub-pixel can selectively filter and reduce other light colors. The color subpixel will display monochrome blue light.

Embodiment 2

[0023] Example 2: Taking the green sub-pixel as an example, the transparent conductive layer is made of ITO material with a thickness of 600-700 Å, and the thickness of the transparent conductive layer is adjusted so that the microcavity effect of the green sub-pixel can selectively filter and reduce other light colors. The pixel will display a monochrome green.

Embodiment 3

[0024] Example 3: Taking the red sub-pixel as an example, the transparent conductive layer is made of IZO material with a thickness of 750-850Å, and the thickness of the transparent conductive layer is adjusted so that the microcavity effect of the red sub-pixel can selectively filter and reduce other light colors. The pixel will display monochromatic red.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com