Optimized supporting method for empty roof area of tunneling roadway

A technology for empty roof area and roof support, which is applied in design optimization/simulation, instrumentation, electrical and digital data processing, etc., can solve the problems of frequent excavation and support operations, roof falling, affecting roadway driving speed, etc., and achieve rapid advancement. The effect of improving and guaranteeing the tunneling speed and increasing the coal output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

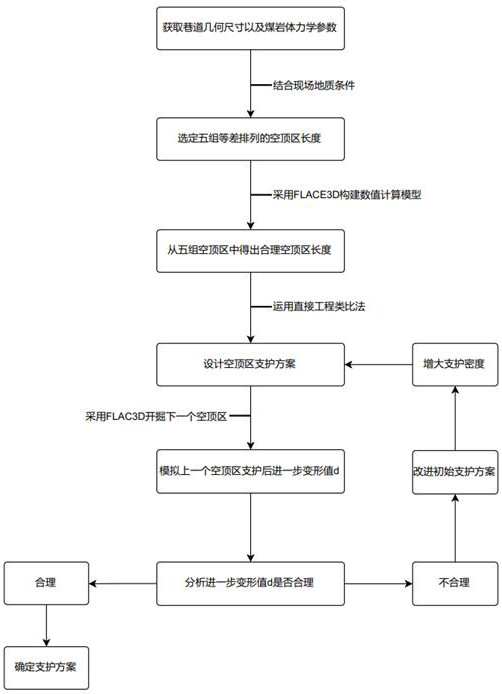

[0012] The specific steps of an optimized support method for the empty roof area of a tunneling roadway are as follows:

[0013] S1: Obtain the geometric parameters of the excavated roadway (roadway width, height), coal and rock mass mechanics experiment parameters (compressive strength, tensile strength, elastic modulus, Poisson's ratio, cohesive force, internal friction angle, thickness);

[0014] S2: Combined with the geological conditions of the site, according to the reasonable length of the empty top area under similar geological conditions as the middle number 12m, determine five groups of different empty top area lengths of 8m, 10m, 12m, 14m, and 16m.

[0015] S3: Using FLAC3D simulation software, based on the geometric parameters of the roadway and the mechanical parameters of coal and rock mass, a numerical calculation model is constructed in equal proportions to simulate the deformation of the roof when the roadway is excavated for 50m and the length of the hollow ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com