Multi-stage fermentation process fault monitoring method of semi-supervised FCM and SAE based on information entropy

A fermentation process and fault monitoring technology, which is applied in the direction of instruments, adaptive control, control/regulation systems, etc., can solve the problems of weakened ability of AE to extract sample characteristics and poor model generalization ability, so as to improve monitoring performance and improve Generalization performance and accurate clustering results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

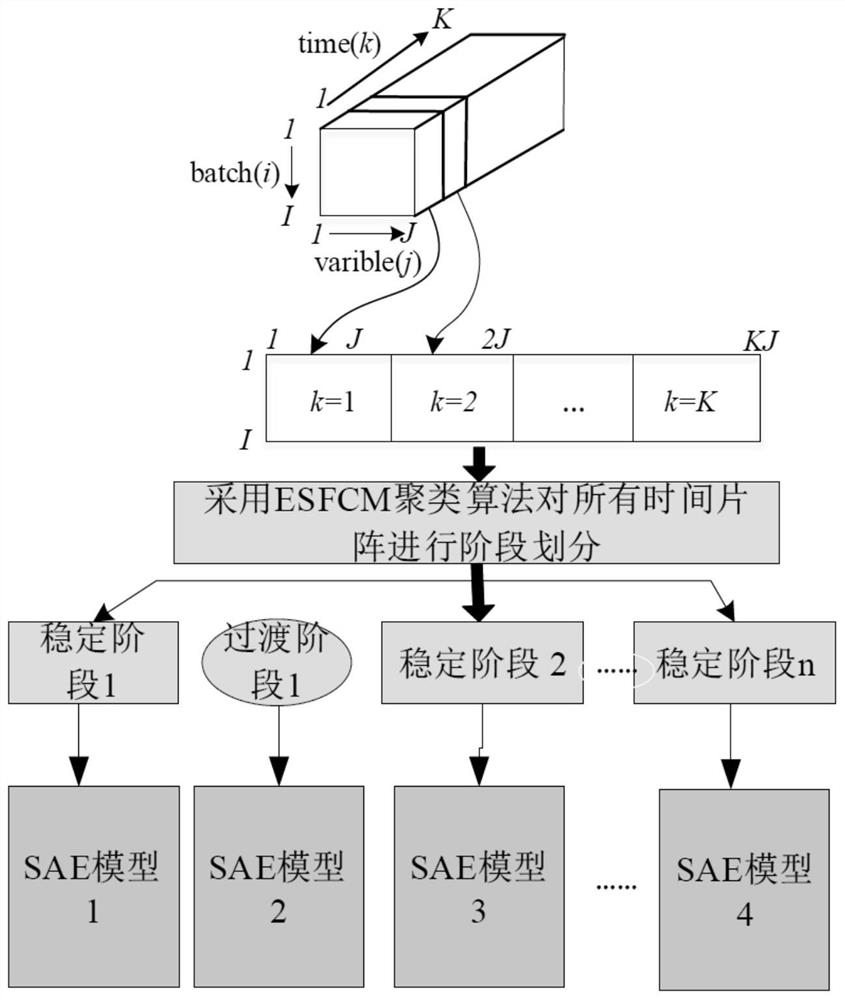

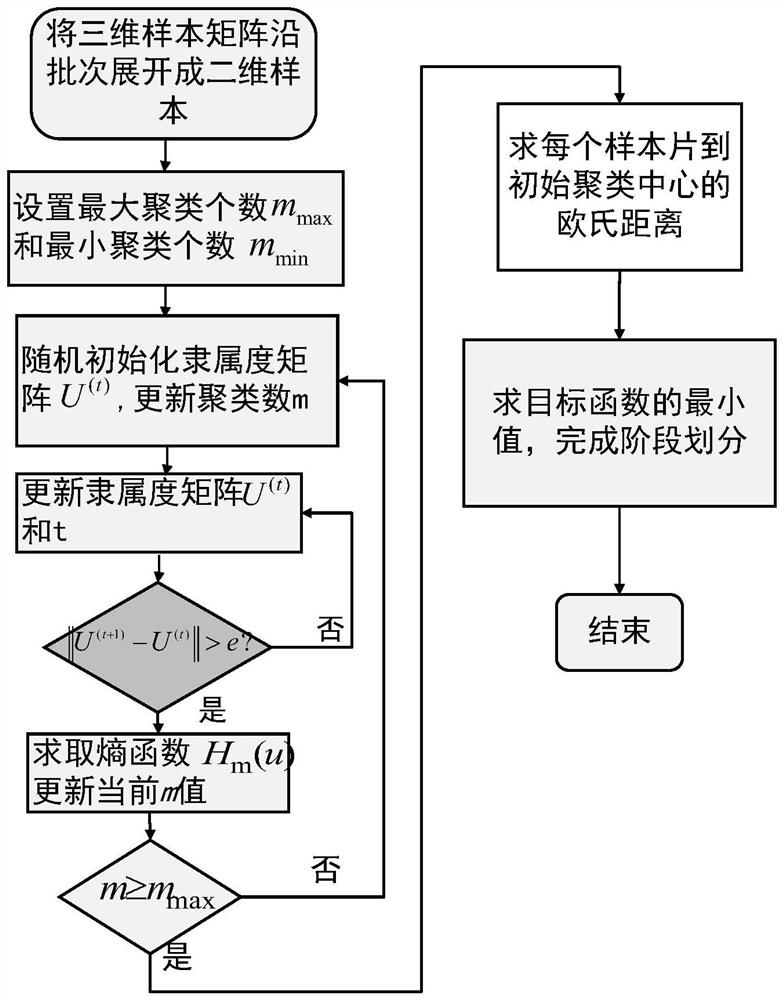

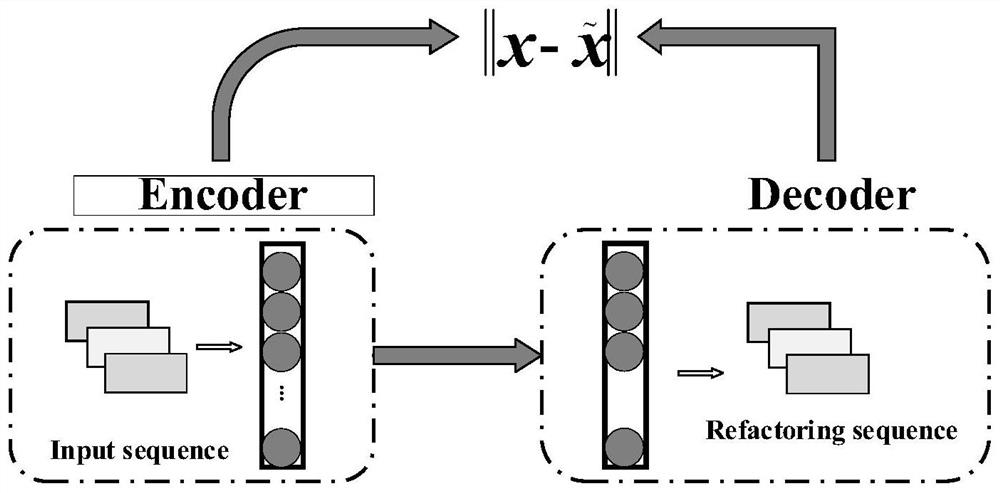

Method used

Image

Examples

Embodiment Construction

[0044] Penicillin (penicillin) Penicillin (penicillin) is a very broad clinical value of antibiotics. This paper uses the international platform Pensim2.0 simulation platform to conduct fault monitoring research on the penicillin fermentation process.

[0045] In this platform, for the convenience of the experiment, the working conditions were set as 400 hours for each batch of continuous fermentation, and the sampling interval was 1 hour. The initial conditions of each batch were slightly changed within the allowable range. 40 batches of normal data are used for simulation, and 10 process variables are selected to obtain 40×400×10 data for offline modeling. The process variables are shown in Table 1. In order to better simulate the actual production situation, a certain amount of Gaussian noise interference is added to the training samples. In order to verify the performance of the proposed method in fault monitoring, this paper selects three groups of fault batch samples ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com