Fault detection method based on analytic hierarchy process and weighted vote decision fusion

An analytic hierarchy process, weighted voting technology, applied in character and pattern recognition, special data processing applications, instruments, etc., can solve problems such as failure to meet actual industrial process monitoring requirements, unfavorable industrial process automation implementation, and inability to achieve satisfactory monitoring results. , to achieve the effect of being conducive to automatic implementation, improving monitoring effect, and improving limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

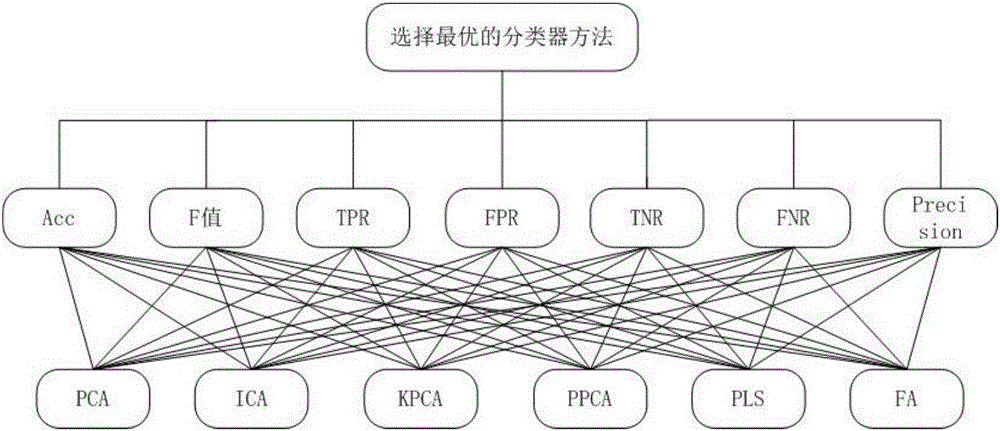

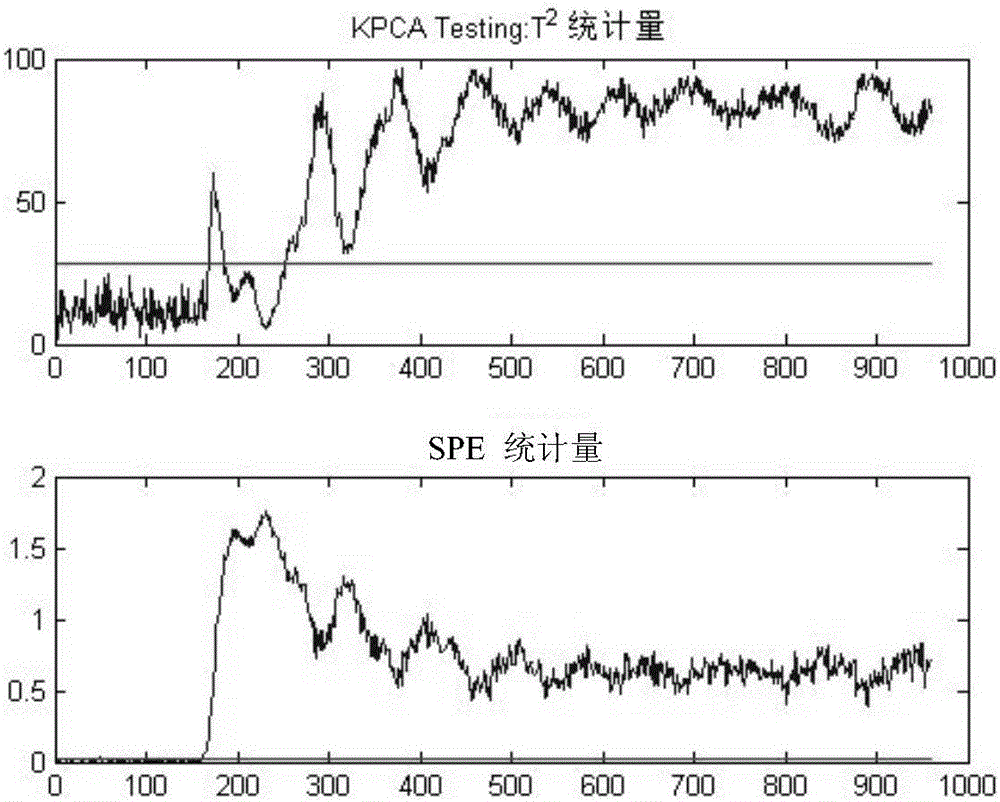

[0021] Aiming at the monitoring problem of industrial process, the present invention first uses the distributed control system to collect data under normal working conditions as a training data set, and then calls different classifier methods respectively, establishes corresponding classifier models, and constructs two monitoring statistics T 2 and SPE and their corresponding statistical limits and SPE lim . Store all process model parameters in the database for future use. When monitoring the new online process data, first use different classifier models to monitor it, and get the corresponding monitoring results. Then, according to the monitoring results of different classifier models, the different classifier models are scored and evaluated by AHP, and finally the monitoring results of different classifiers are integrated and fused by combining the weighted voting decision fusion method to obtain the final monitoring results.

[0022] The main steps of the technical sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com