Hydrogen sulfide analyzer

An analyzer, a technology of hydrogen sulfide, applied in the analysis of materials, analysis by chemical reaction of materials, and material analysis by observing the impact on chemical indicators, which can solve the problems of difficult cleaning, poor humidity, and inaccurate analysis. and other problems to achieve the effect of increasing purity and avoiding vulcanization overload.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The implementation of the present application will be described in detail below with reference to the accompanying drawings and examples, so as to fully understand and implement the implementation process of how the present application uses technical means to solve technical problems and achieve technical effects.

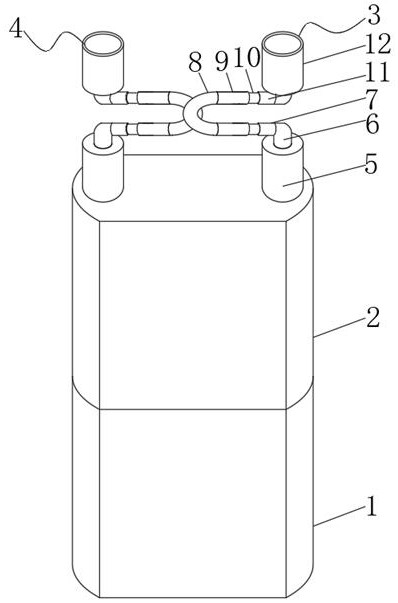

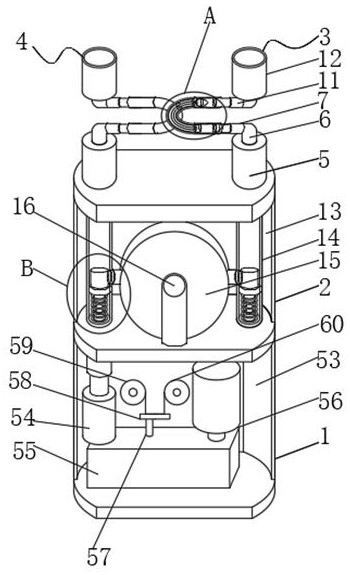

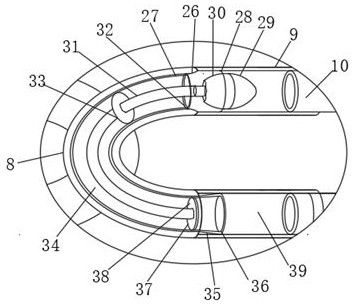

[0024] like Figure 1-6 As shown, the present invention provides a hydrogen sulfide analyzer, comprising: an analysis device 1, the top of the analysis device 1 is fixedly connected with a content proportioning device 2, and the left and right sides of the content proportioning device 2 top are respectively provided with a second inlet Trachea device 4 and the first air inlet pipe device 3, the first air inlet pipe device 3 and the second air inlet pipe device 4 have the same structure, the first air inlet pipe device 3 comprises connecting pipe 5, and the top of connecting pipe 5 communicates with connecting elbow 6. One end of the connecting elbow 6 is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com