Fabricated toilet

A toilet, prefabricated technology, applied in the toilet field, can solve the problems of empty drum on the ground, large leveling, and high manufacturing cost of waterproof chassis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

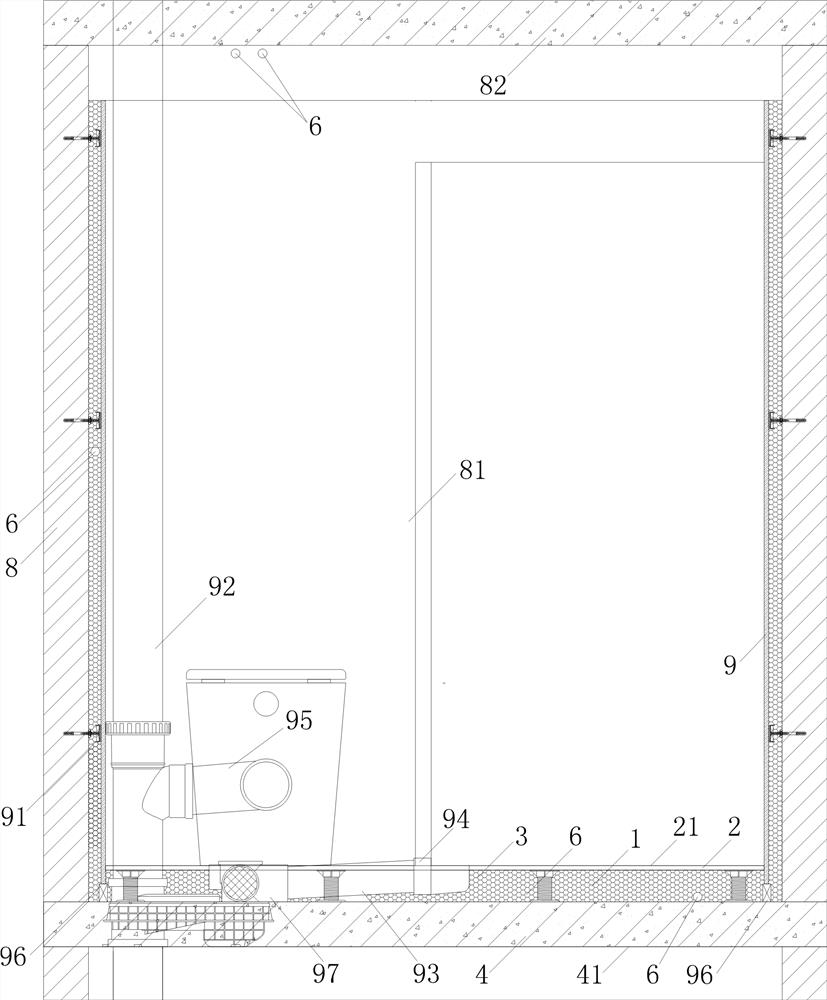

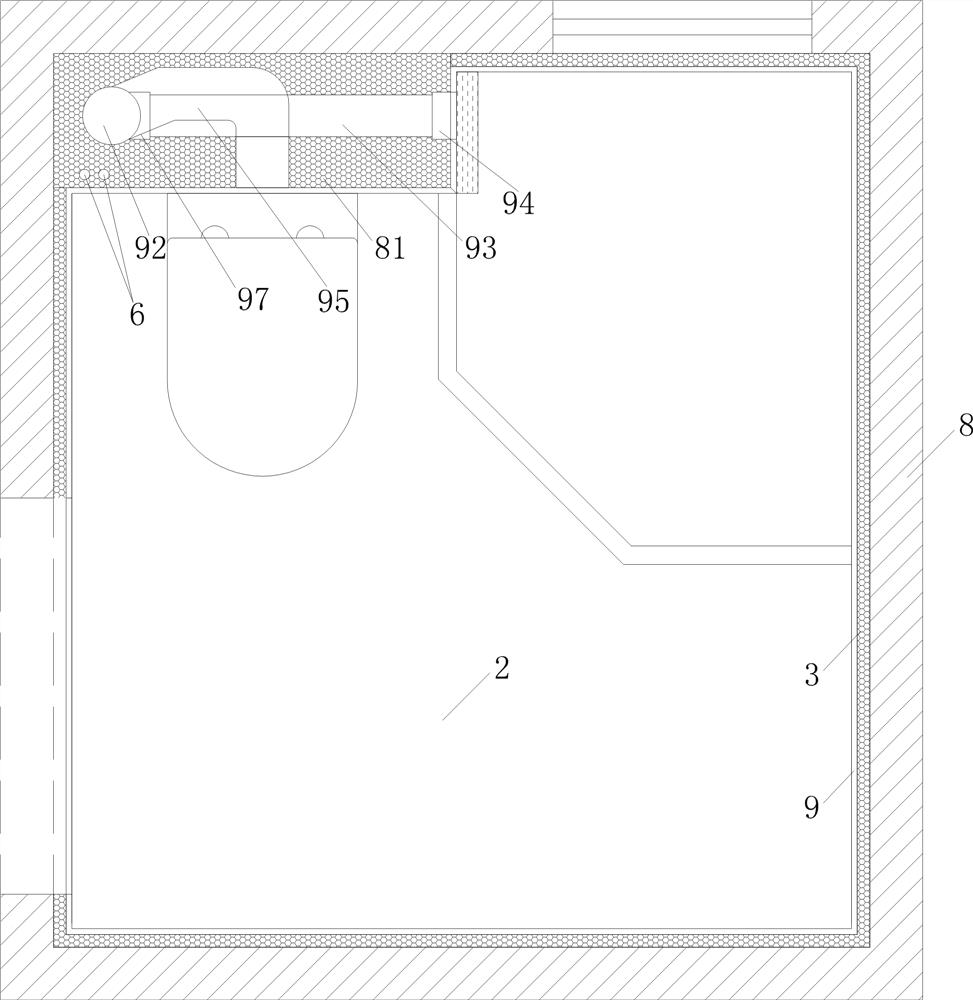

[0015] Such as figure 1 , 2 As shown, the prefabricated toilet includes a support member 1, a decorative floor 2, a waterproof foam material 3, a structural floor 4, a structural wall 8, a waterproof wall panel 9, a wall keel 91, an integrated pipeline maintenance well 81, Structural top surface 82, drainage standpipe 92, waste water horizontal branch pipe 93, drain outlet 94, sewage horizontal branch pipe 95; it is characterized in that support 1 is above structural floor 4, decorative floor 2 is above support 1, and support 1 is under the head It is fixed with the structural floor 4, and the upper part is fixed with the decorative floor 2; the wall keel 91 is fixed on the structural wall 8, the waterproof wall panel 9 is fixed on the wall keel 91, and the waterproof wall panel 9 outside the area of the pipeline integrated maintenance shaft 81 The gap between the back and the structural wall 8 is 30mm; the bottom of the waterproof wall panel 9 is 35mm higher than the struc...

Embodiment 2

[0017] Such as figure 1 , 2 As shown, in the prefabricated toilet, there is a pipeline 6 in the gap between the back of the waterproof wall panel 9 and the structural wall surface 8, and all water supply, drainage, and wire pipelines other than the source pipelines entering the toilet wall are not buried in the structural wall surface. 8; the bottom of the waterproof wallboard 9 has a support frame 96; the bottom of the structure top surface 82 and the top of the waterproof wallboard 9 have a pipeline 6.

Embodiment 3

[0019] Such as figure 1 As shown, in the prefabricated toilet, there is a pipeline 6 in the space below the decorative floor 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com