Light-weight high-performance concrete for fabricated bridge and preparation method of light-weight high-performance concrete

A technology for high-performance concrete and bridges, applied in clay preparation devices, chemical instruments and methods, manufacturing tools, etc., can solve the problems of poor durability and heavy quality, and achieve the effects of good durability, light weight and wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

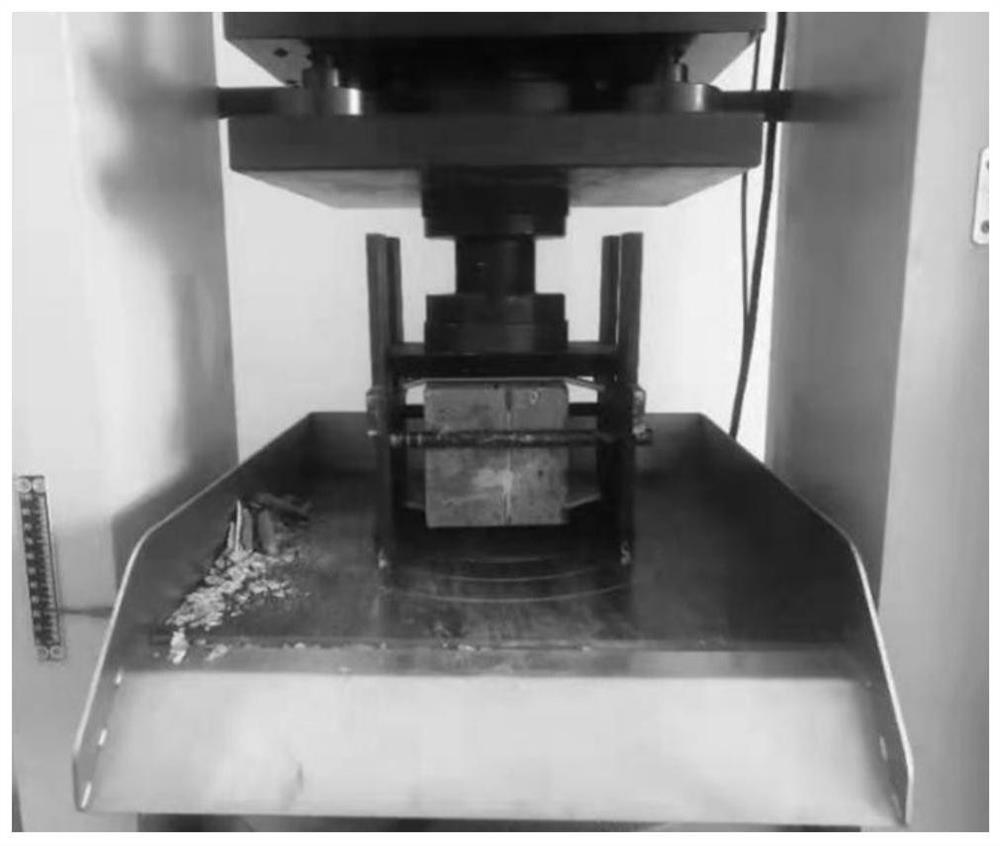

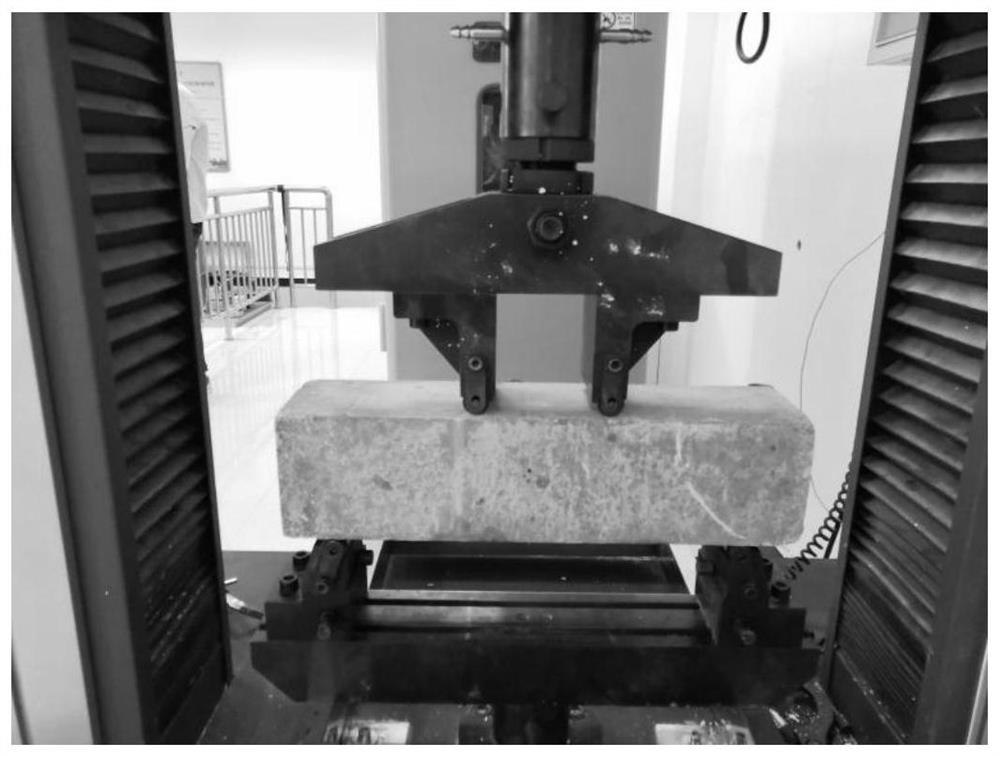

Image

Examples

Embodiment 1

[0048] Embodiment 1 A preparation method of lightweight high-performance concrete for prefabricated bridges, comprising the following steps:

[0049] (1) Screening of vanadium tailings ceramsite: screening vanadium tailings ceramsite with a particle size of 10mm, wherein the cylinder compressive strength of ceramsite is ≥6MPa, water absorption ≤10%, and bulk density ≤800kg / m 3 .

[0050] (2) Interface treatment on the surface of ceramsite:

[0051] First, use compressed air to dedust the surface of the ceramsite;

[0052] Then, prepare a water-based epoxy resin emulsion: mix component A and component B in a mass ratio of 2:1, and stir until a uniform emulsion is formed, that is, a water-based epoxy resin emulsion. Among them, component A is mixed by the following raw materials in parts by weight: 90 parts of water-based epoxy resin, 10 parts of epoxy reactive diluent BGE, 0.1 part of dispersant trichlorotrifluoroethane, polydiethylene glycol with a molecular weight of 15000 ...

Embodiment 2

[0064] Embodiment 2 A preparation method of lightweight high-performance concrete for prefabricated bridges, comprising the following steps:

[0065] (1) Screening of vanadium tailings ceramsite: screening vanadium tailings ceramsite with a particle size of 10mm, wherein the cylinder compressive strength of ceramsite is ≥6MPa, water absorption ≤10%, and bulk density ≤800kg / m 3 .

[0066] (2) Interface treatment on the surface of ceramsite:

[0067] First, use compressed air to dedust the surface of the ceramsite;

[0068] Then, prepare a water-based epoxy resin emulsion: mix component A and component B in a mass ratio of 2:1, and stir until a uniform emulsion is formed, that is, a water-based epoxy resin emulsion. Among them, component A is mixed with the following raw materials by weight: 90 parts of water-based epoxy resin, 10 parts of epoxy reactive diluent BGE, 0.1 part of dispersant trichlorotrifluoroethane, and poly(difluoroethylene) with a molecular weight of 15000 as...

Embodiment 3

[0081] Embodiment 3 A preparation method of lightweight high-performance concrete for prefabricated bridges, comprising the following steps:

[0082] (1) Screening of vanadium tailings ceramsite: screening vanadium tailings ceramsite with a particle size of 15mm, wherein the cylinder compressive strength of ceramsite is ≥6MPa, water absorption ≤10%, and bulk density ≤800kg / m 3 .

[0083] (2) Interface treatment on the surface of ceramsite:

[0084] First, use compressed air to dedust the surface of the ceramsite;

[0085] Then, prepare the water-based epoxy resin emulsion: mix and stir the components A and B at a mass ratio of 2:1 until a uniform emulsion is formed, that is, the water-based epoxy resin emulsion. Among them, component A is mixed with the following raw materials by weight: 90 parts of water-based epoxy resin, 10 parts of epoxy reactive diluent BGE, 0.1 part of dispersant trichlorotrifluoroethane, and poly(difluoroethylene) with a molecular weight of 15000 as a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com