Two-stage sulfide wastewater degradation device based on hydrodynamic cavitation

A wastewater degradation device and a technology of hydrodynamic cavitation, applied in the field of pollutant degradation, can solve the problems of low efficiency, hydrogen sulfide gas emission, and inapplicability, and achieve the effects of high efficiency, large processing capacity and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

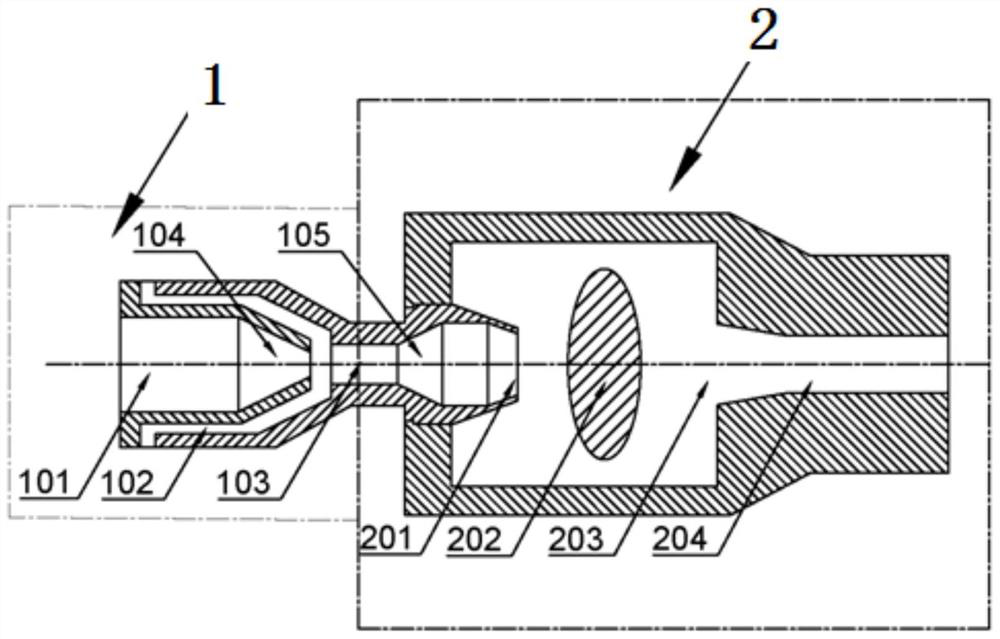

[0037] The double-stage degradation device for sulfide wastewater based on hydraulic cavitation of the present invention, such as figure 1 As shown, it includes a cavitation jet tube 1 and a reaction chamber 2. One end of the cavitation jet tube 1 is provided with a liquid inlet 101 and an oxidant channel 102, and the other end is provided with a nozzle 201. The inside of the cavitation jet tube 1 is located at the liquid inlet. A throat 103 is provided between the nozzle 101 and the nozzle 201 . The liquid inlet 101, the oxidant channel 102 and the throat 103 form a mixing zone. Between the liquid inlet 101 and the throat 103 is a tapered incident section 104 that shrinks along the direction of liquid flow. A tapered exit section 105 is provided between the nozzle 201 and the throat 103, expanding along the liquid flow direction.

[0038] The oxidant channel 102 is arranged in the side wall of the cavitation jet tube 1 and is connected to the throat 103. The inner diameter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com