Dry production and treatment equipment for coffee beans

A technology for processing equipment and coffee beans, applied in food processing, chemical instruments and methods, solid separation, etc., can solve problems such as affecting people's work efficiency, not automatically turning coffee beans, and low efficiency of sieving and peeling coffee beans. To achieve the effect of convenient processing, improve work efficiency and improve drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

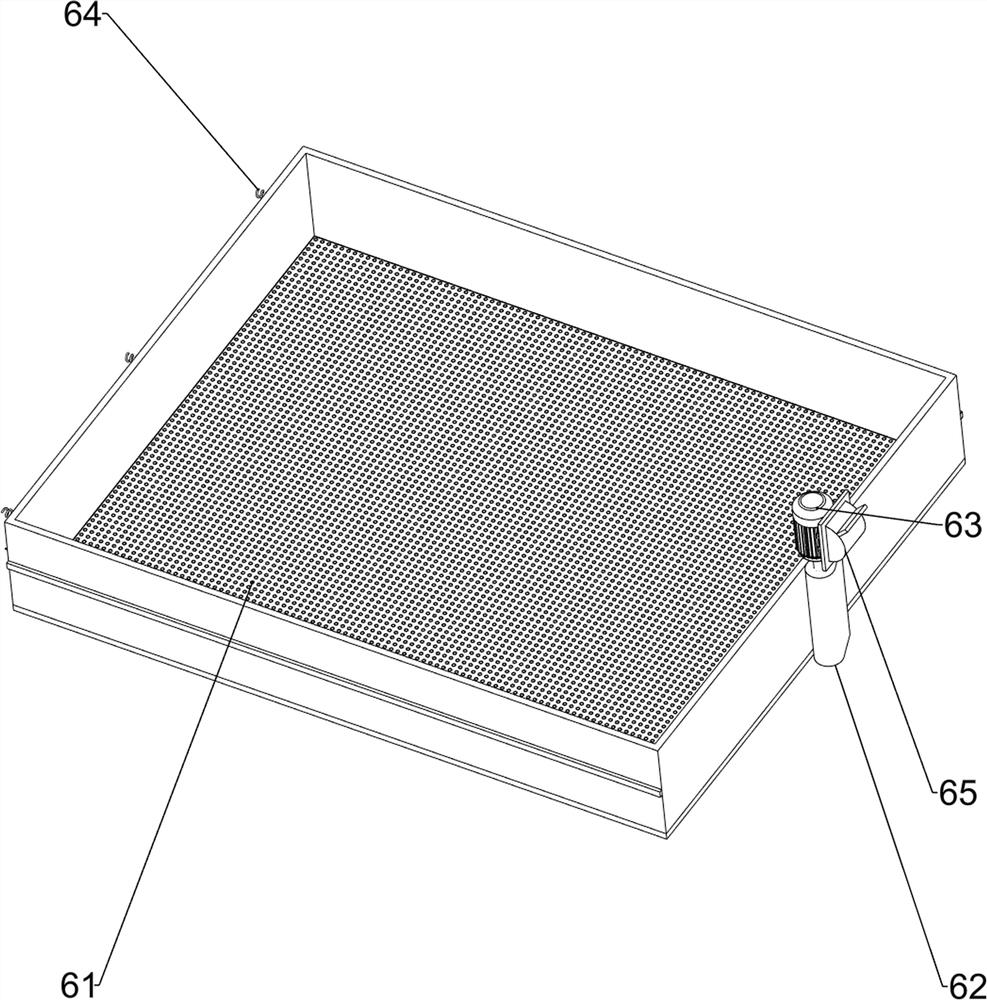

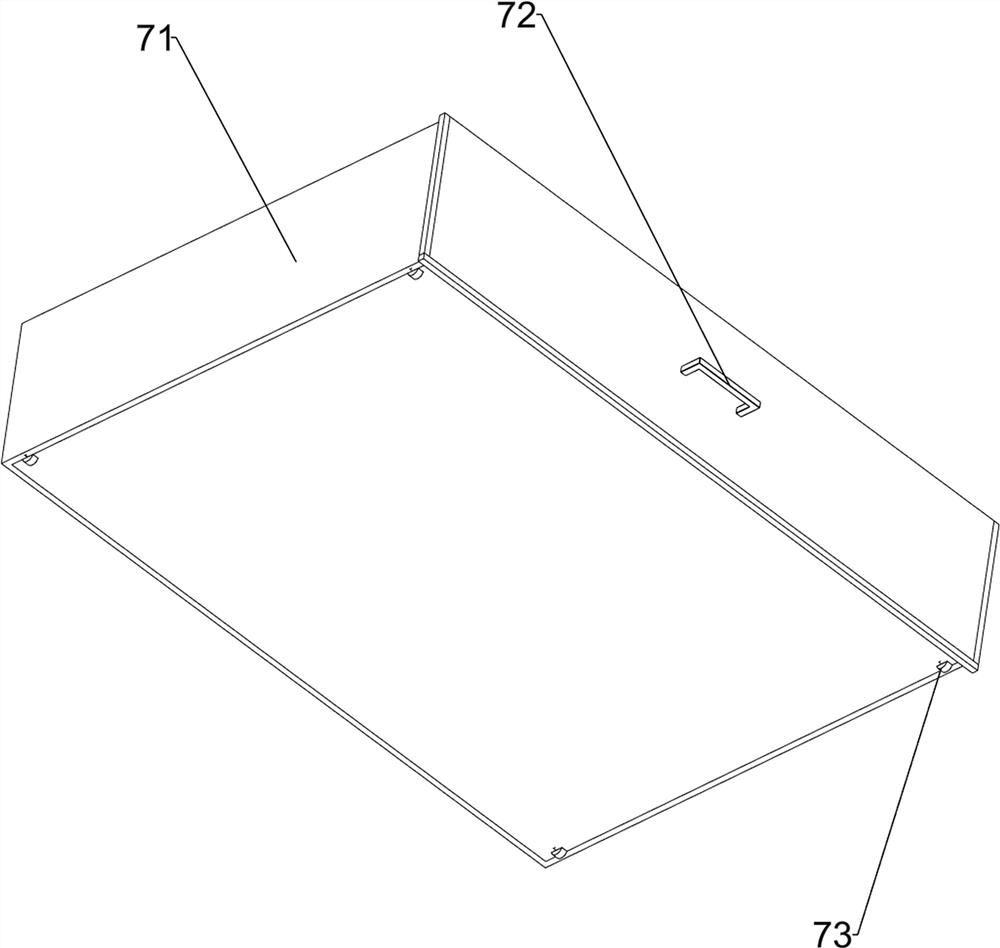

[0039] A kind of coffee bean dry method production processing equipment, such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 and Figure 8 As shown, it includes a casing 1, a heating block 11, a touch switch 12, a drying plate 13, a door panel 14, a universal wheel 15, a drying mechanism 2 and a drying mechanism 3, and a drying mechanism 2 is installed on the upper side of the casing 1. A plurality of heating blocks 11 are evenly spaced inside the mechanism 2. Touch switches 12 are symmetrically installed on the left and right sides of the top of the housing 1. The touch switches 12 and the heating blocks 11 are electrically connected. Mechanism 3, airing mechanism 3 inboard left and right symmetrical rotations are connected with drying plate 13, and shell 1 front side is rotatably equipped with door panel 14, and all front and rear symmetric rotations of shell 1 bottom left and right sides are connected with universal wheel 15.

[00...

Embodiment 2

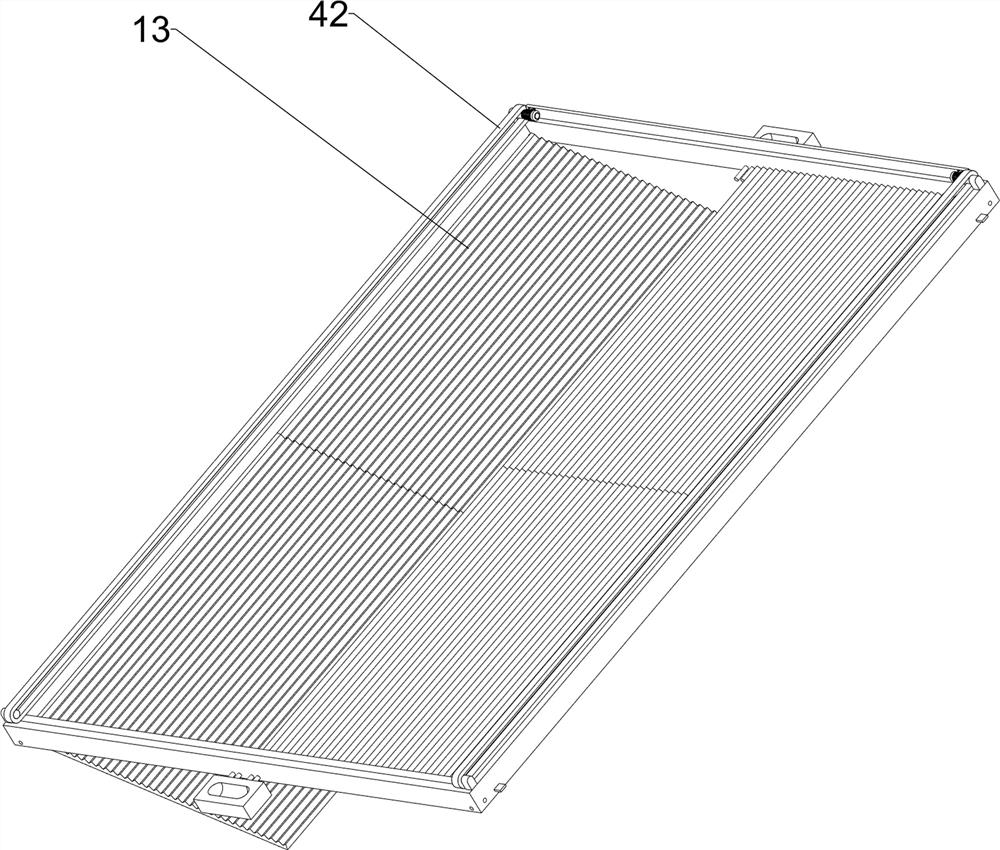

[0044] On the basis of Example 1, such as figure 2 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 , Figure 11 , Figure 14 , Figure 15 , Figure 16 , Figure 17 , Figure 18 and Figure 19 Shown, also comprise turning mechanism 4, and turning mechanism 4 comprises stirring bar 41, driving belt 42, fixed block 43, first motor 44 and driving wheel 45, and fixed frame 31 top left and right sides all front and back symmetrical fixed connections have Fixed block 43, fixed block 43 inboards are all rotatably equipped with drive wheel 45, and drive belt 42 is all wound around between the front and rear two drive wheels 45 on the left and right sides, is connected with stirring lever 41 between drive belt 42 inboards, inside fixed frame 31 A first motor 44 is mounted symmetrically on the rear side left and right, and the output shafts of the first motor 44 are all connected to the transmission wheel 45 on the rear side.

[0045] After the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com