Wafer-level LED packaging structure capable of dissipating heat

A LED packaging and wafer-level technology, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of low heat dissipation efficiency and low stability of wafer-level LED packaging structure, and achieve faster heat dissipation, improved ventilation performance, and improved The effect of mounting stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

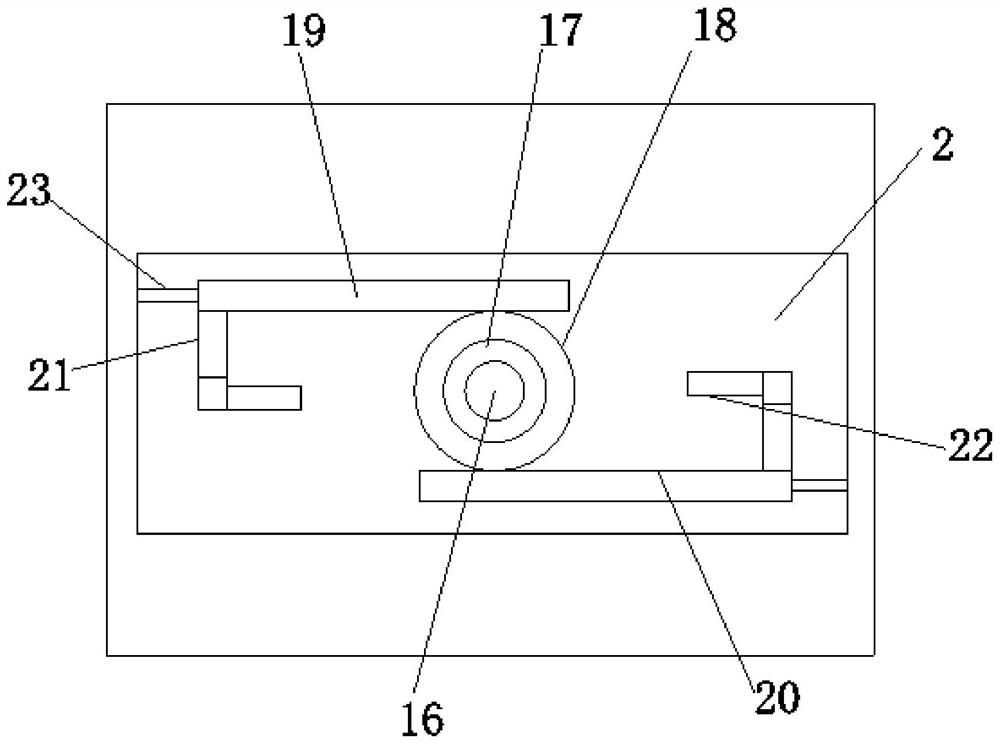

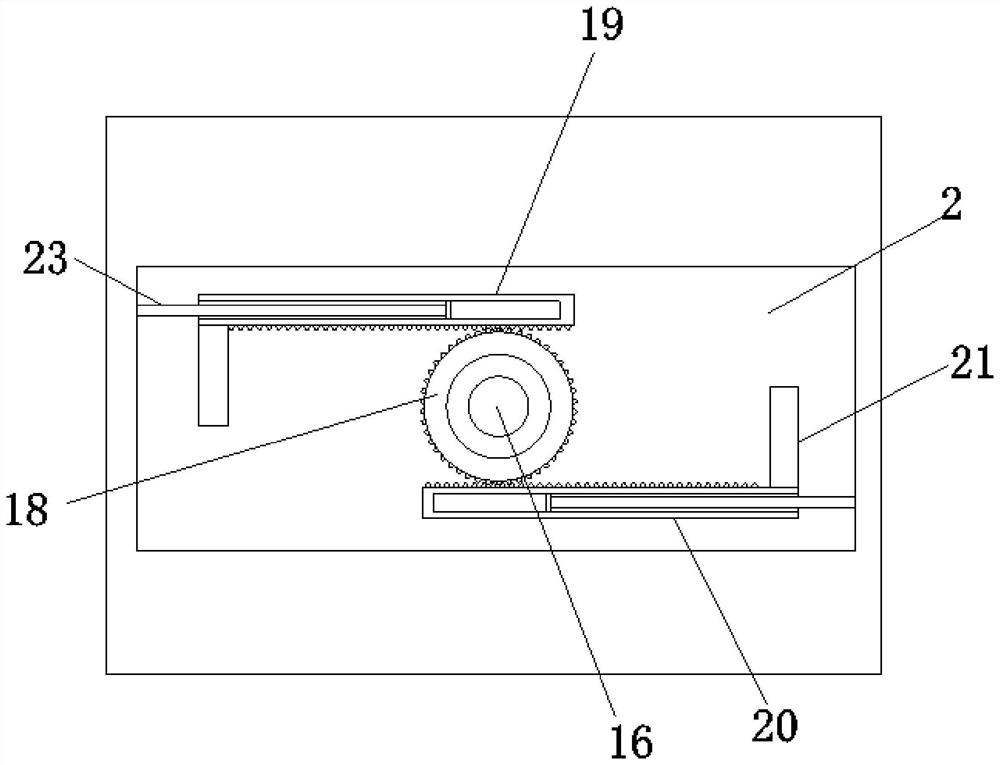

[0036] Embodiment one, by Figure 1 to Figure 9 Given, the present invention comprises silicon base 1, and the interior of silicon base 1 is provided with accommodating groove one 2 and accommodating groove two 3, and accommodating groove one 2 is positioned at the top of accommodating groove two 3, and the top of silicon base 1 is provided with installation Groove 4, the inside of the installation groove 4 is equipped with a mounting base 5, the inside of the mounting base 5 is provided with an LED chip 6, the top of the mounting base 5 is equipped with a convex lens plate 7, and the outer wall of the LED chip 6 is provided with a fluorescent lamp located inside the mounting base 5. Powder layer 8, the top of silicon base 1 is provided with the lens protective cover 9 that is sleeved on the outer wall of mounting seat 5, is connected by screw rod 26 between lens protective cover 9 and silicon base 1, and the inside of accommodating groove-2 is provided with The installation mec...

Embodiment 2

[0040] Embodiment two, on the basis of embodiment one, by figure 1 It is given that the cooling rod 13 has a wave-shaped structure, and the cooling rod 13 is equidistantly provided with cooling holes 50, and the design of the cooling rod 13 and the cooling hole 50 in a wave-shaped structure effectively increases the contact between the cooling rod 13 and the air. area, thereby speeding up the heat dissipation efficiency of the heat dissipation rod 13, and further speeding up the heat dissipation speed of the LED chip 6.

Embodiment 3

[0041] Embodiment three, on the basis of embodiment one, by figure 1 , Figure 4 with Figure 5 Given, the pressing group includes a fixed cylinder 27, an annular groove 28, an annular rod 29, a pressing rod 30, a movable groove 31 and a spring, and the top of the silicon base 1 is provided with a fixed cylinder 27 sleeved on the outside of the lens protective cover 9. The inside of the barrel 27 is provided with an annular groove 28, and the interior of the annular groove 28 is provided with an annular rod 29. The annular rod 29 and the annular groove 28 are connected by equidistant springs. Through the active groove 31, the inner wall of the fixed cylinder 27 is symmetrically provided with a pressing rod 30, and one end of the pressing rod 30 runs through the movable groove 31 and is connected with the side wall of the annular rod 29, and the pressing rod 30 is located at the top of the screw rod 26;

[0042] The staff pulls the pressing rod 30 upwards, so that the pressin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com