Method for long-distance wire passing or pressure guiding in narrow structure space

An in-space, long-distance technology, applied in earthwork drilling, rigid pipe, measurement, etc., can solve the problems of difficult processing, high processing cost, high risk, etc., and achieve the goal of improving applicability and versatility and reducing processing cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

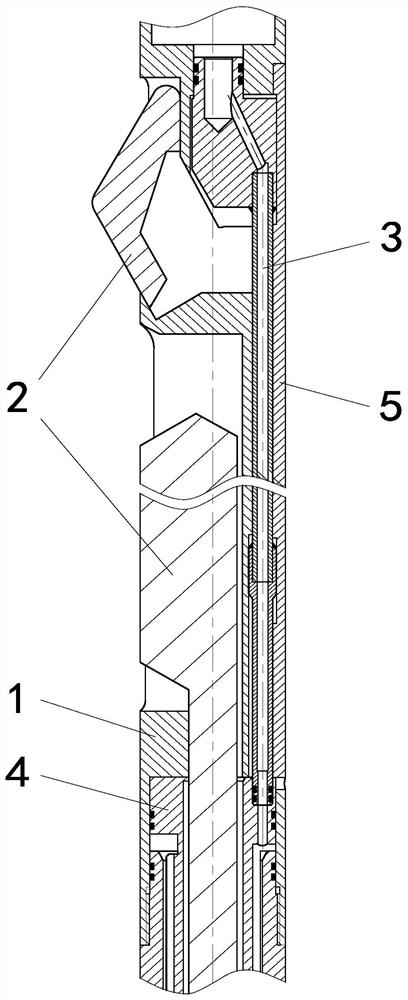

[0025] A method of passing wires or conducting pressure over a long distance in a narrow structural space of the present invention, such as figure 1 As shown, the method is to set a groove on the side of the instrument body 1 away from the device 2 in the instrument, and install the wire or pressure guide assembly 3 in the groove, and connect the upper end of the wire or pressure guide assembly 3 to the instrument body. 1 Sealed connection, the lower end of the wire or pressure guide assembly 3 is sealed and connected with the sealing tube 4 at the lower end of the instrument body 1; then the wire or pressure guide assembly 3 is packaged in the groove of the instrument body 1 through the cover plate 5.

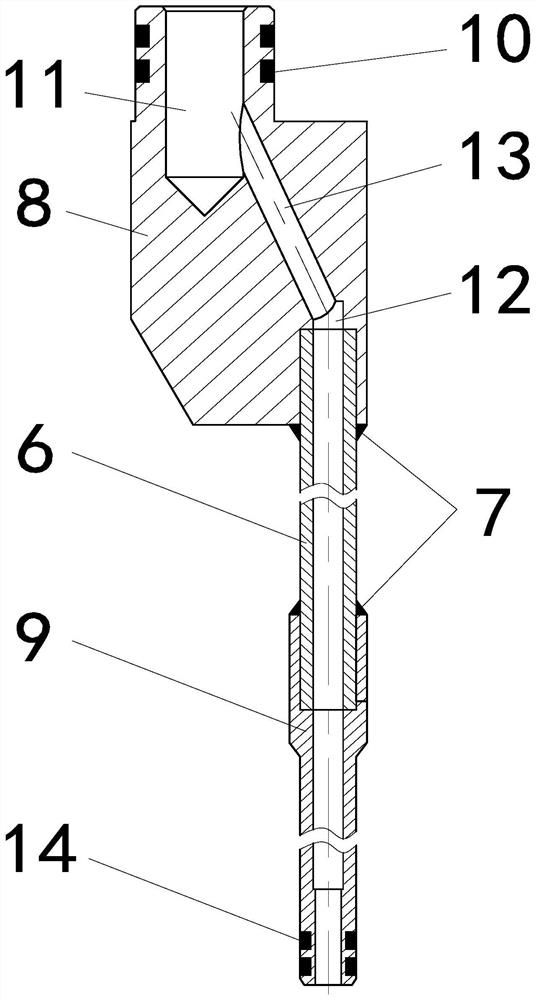

[0026] Such as figure 2 As shown, the wire passing or pressure guide assembly 3 is divided into three sections, including the stainless ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com