Efficient grouting construction method for prefabricated shear wall

A construction method and technology of prefabricated shear force, which are applied in the treatment of walls, building materials, structural elements, etc., can solve the problems affecting the overall mechanical performance and seismic performance of prefabricated shear walls, insufficient holding time of grouting machine, and construction. Structural safety buried and other issues, to achieve the effect of saving grouting time, improving grouting density, and improving grouting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0018] A high-efficiency grouting construction method for prefabricated shear walls, comprising the following steps:

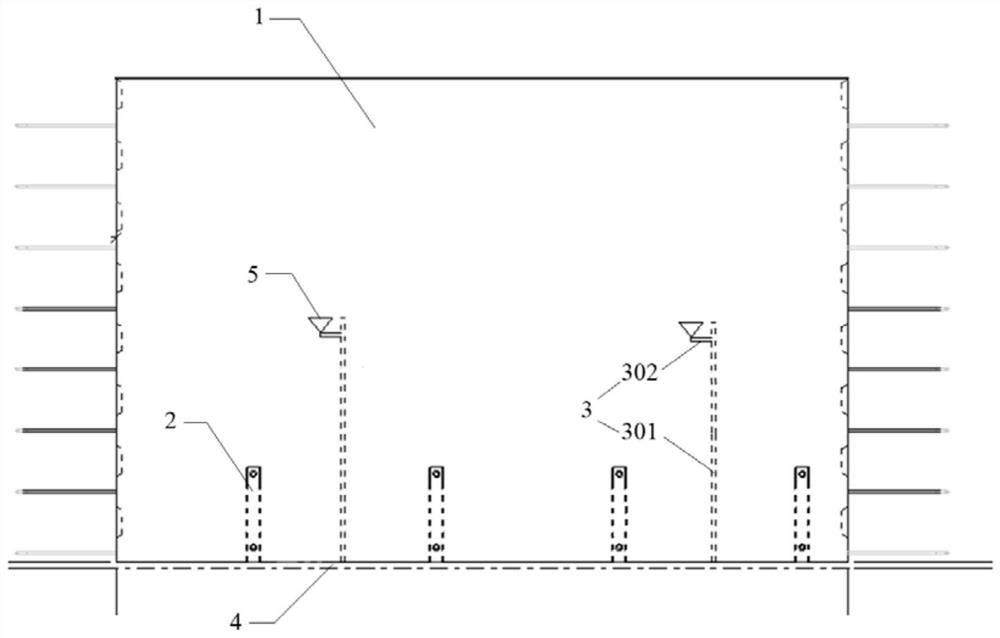

[0019] (1) Prefabricated shear wall: During the prefabrication process of the shear wall, a number of grouting sleeves 2 and grouting observation tubes 3 are pre-embedded in the shear wall to obtain a prefabricated shear wall; the bottom of the prefabricated shear wall 1 is provided with grouting The channel 4, the bottom of the grouting sleeve 2 and the bottom of the grouting observation tube 3 are all in communication with the grouting channel 4; the height of the top of the grouting observation tube 3 is higher than the height of the top of the grouting sleeve 2; the grouting observation tube 3 includes an integrally connected vertical Part 301 and horizontal part 302, the vertical part 301 is pre-buried inside the prefabricated shear wall 1, and the horizontal part 302 extends out of the prefabricated shear wall to communicate with the outside world. Speci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com