Organic fertilizer for preventing soil hardening damage and production method thereof

A technology of soil compaction and production method, applied in fertilization devices, fertilizer mixtures, applications, etc., can solve problems such as inability to grow, inability to satisfy users, and death, and achieve the effect of increasing salinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

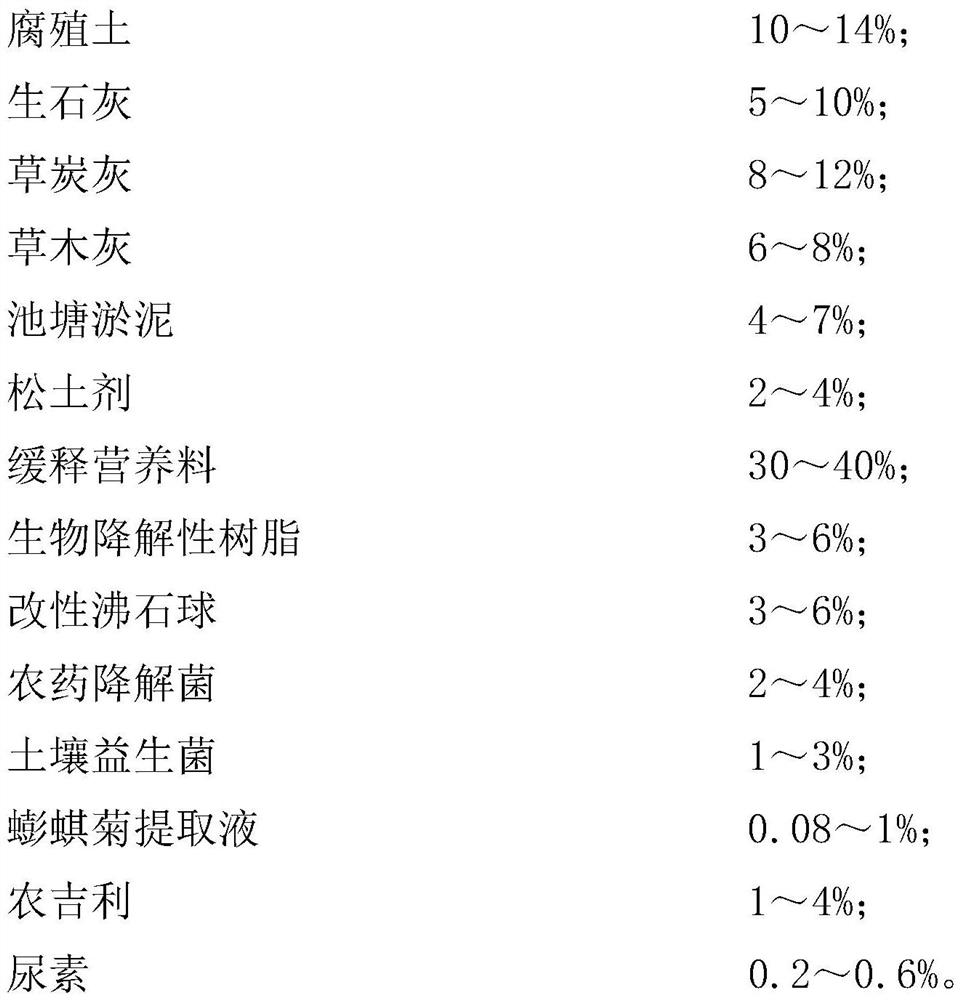

[0048] 1) weighing, with the humus of 12% weight portion, the quicklime of 8% weight portion; The peat ash of 10% weight portion; The plant ash of 7% weight portion; The pond mud of 6% weight portion; Soil loosening agent; 35% by weight of slow-release nutrient; 5% by weight of biodegradable resin; 5% by weight of modified zeolite balls; 3% by weight of pesticide degrading bacteria; 2% by weight of soil probiotics Bacteria; 0.5% by weight of Wedelia extract; 3% by weight of Nongjili; 0.5 by weight of urea;

[0049] 2) preparing a mixture, adding the weighed pesticide-degrading bacteria and the soil probiotics after preparing the biodegradable resin mixed with gelatin to obtain a mixture;

[0050] 3) Preparation of spare materials: take the weighed modified zeolite balls and mix them with the Nongjili, Wedelia extract, and slow-release nutrients to obtain spare materials;

[0051] 4) preparing additives, mixing the humus, quicklime, peat ash, plant ash, pond corn, soil looseni...

Embodiment 2

[0058] 1) weighing, with the humus of 10% weight portion, the unslaked lime of 5% weight portion; The peat ash of 8% weight portion; The plant ash of 6% weight portion; The pond mud of 4% weight portion; Soil loosening agent; 30% by weight of slow-release nutrient; 3% by weight of biodegradable resin; 3% by weight of modified zeolite balls; 2% by weight of pesticide degrading bacteria; 1% by weight of soil probiotics Bacteria; 0.08% by weight of Wedelia extract; 1% by weight of Nongjili; 0.2% by weight of urea;

[0059] 2) preparing a mixture, adding the weighed pesticide-degrading bacteria and the soil probiotics after preparing the biodegradable resin mixed with gelatin to obtain a mixture;

[0060] 3) Preparation of spare materials: take the weighed modified zeolite balls and mix them with the Nongjili, Wedelia extract, and slow-release nutrients to obtain spare materials;

[0061] 4) preparing additives, mixing the humus, quicklime, peat ash, plant ash, pond corn, soil lo...

Embodiment 3

[0068] 1) weighing, with the humus of 14% weight portion, the quicklime of 10% weight portion; The peat ash of 12% weight portion; The plant ash of 8% weight portion; The pond mud of 7% weight portion; Soil loosening agent; 40% by weight of slow-release nutrient; 6% by weight of biodegradable resin; 6% by weight of modified zeolite balls; 4% by weight of pesticide degrading bacteria; 3% by weight of soil probiotics bacteria; 1% by weight of Wedelia extract; 4% by weight of Nongjili; 0.6% by weight of urea;

[0069] 2) preparing a mixture, adding the weighed pesticide-degrading bacteria and the soil probiotics after preparing the biodegradable resin mixed with gelatin to obtain a mixture;

[0070] 3) Preparation of spare materials: take the weighed modified zeolite balls and mix them with the Nongjili, Wedelia extract, and slow-release nutrients to obtain spare materials;

[0071] 4) preparing additives, mixing the humus, quicklime, peat ash, plant ash, pond corn, soil looseni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com