Self-adaptive electric control vacuum chuck manipulator for label-removed waste plastic bottles and control method

A technology for vacuum suction cups and waste plastics, applied in the field of manipulators, can solve problems such as affecting the sorting efficiency of industrial robots, unable to ensure the air tightness of suction cups, reducing the service life of manipulators, etc., to achieve data management and monitoring, simple structure, and easy installation. with fast effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in more detail below in conjunction with the accompanying drawings.

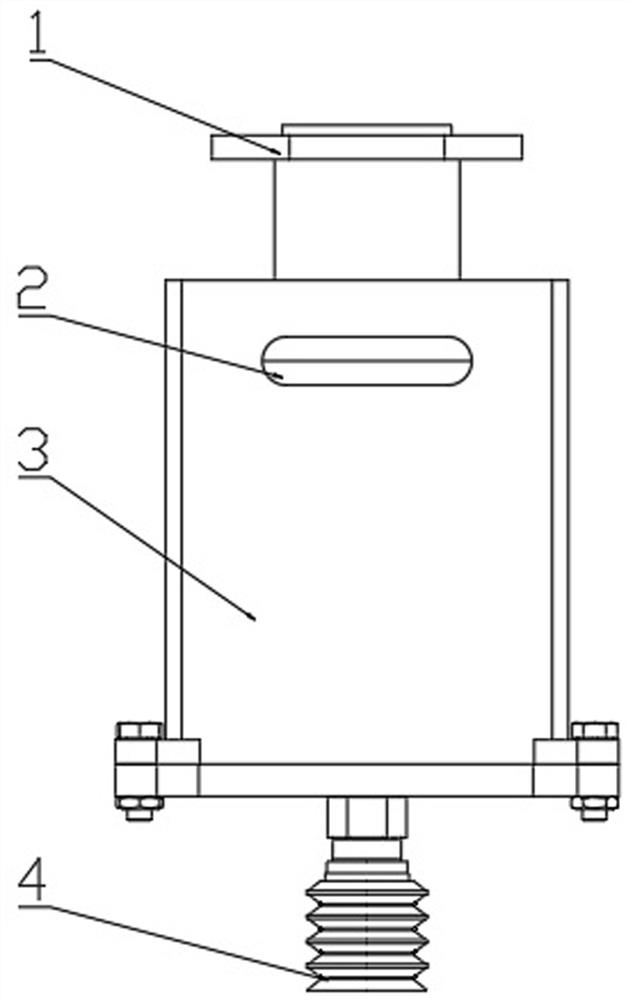

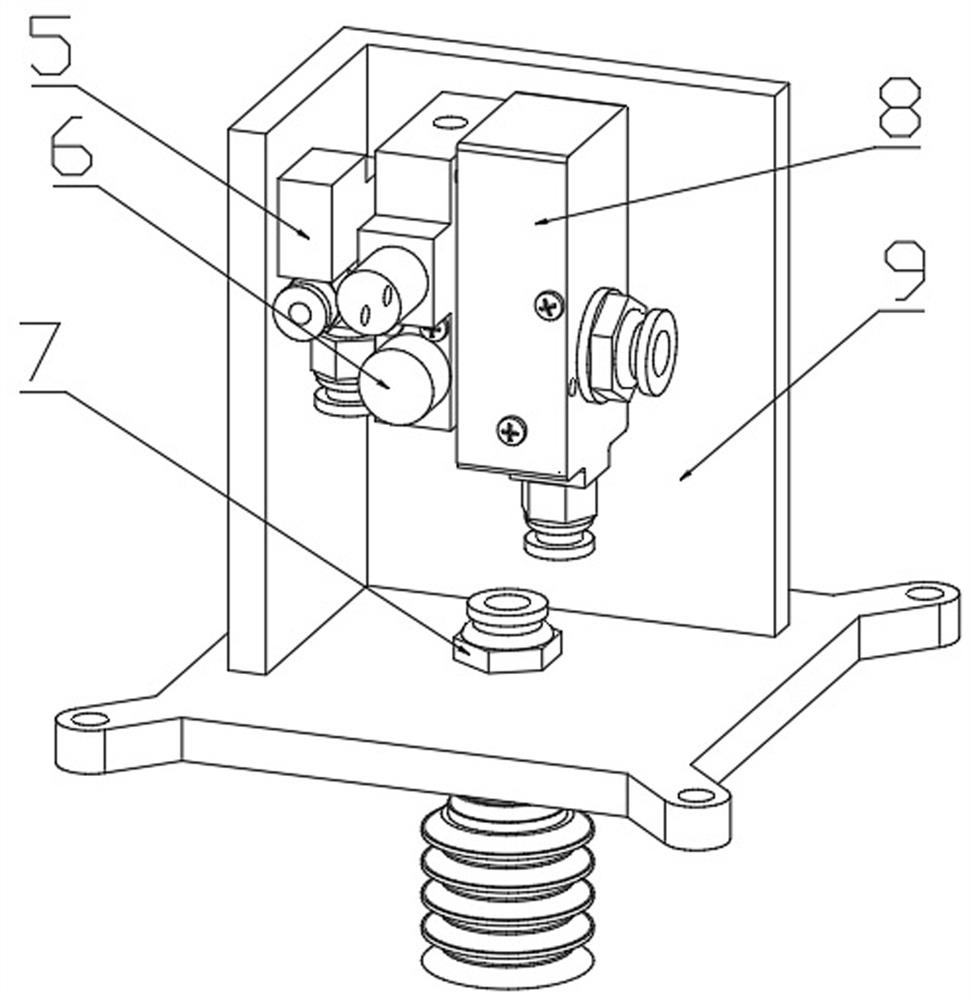

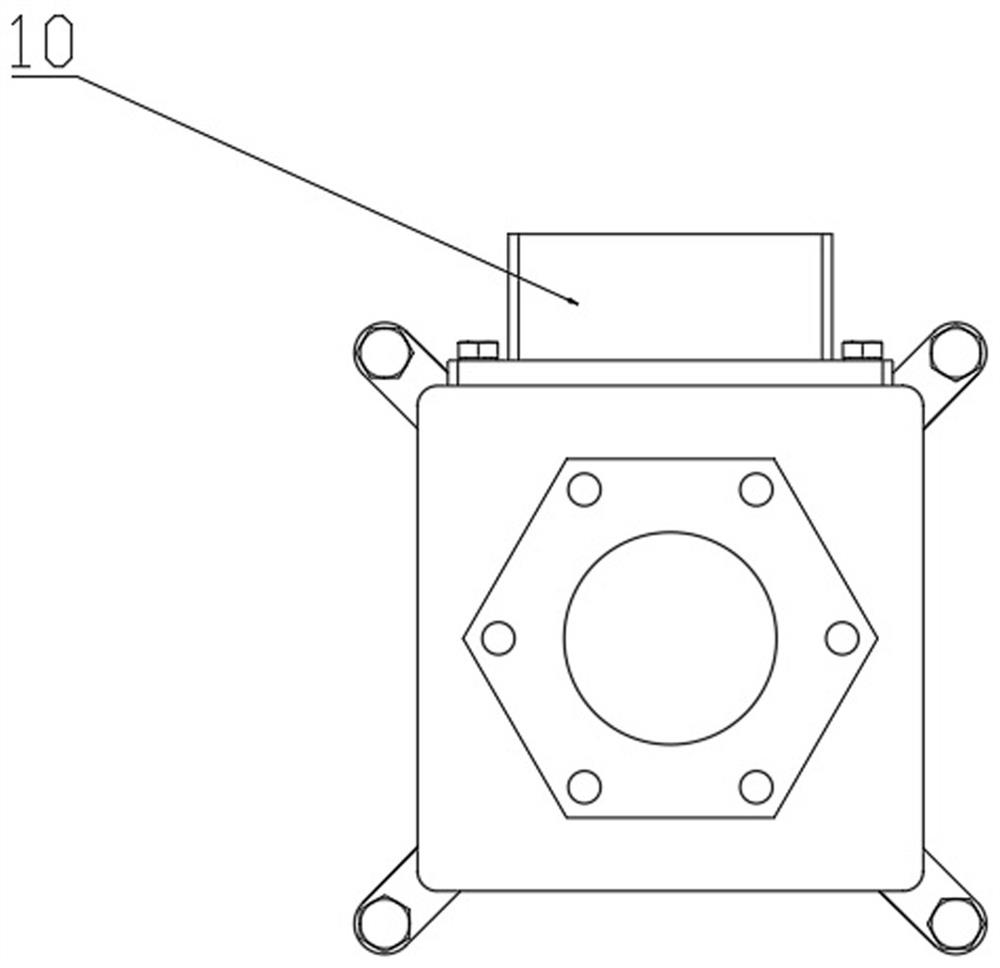

[0039] Such as Figure 1-4As shown, an electronically controlled vacuum suction cup manipulator for off-label waste plastic bottles can absorb plastic disks with complex surfaces, and can judge whether the suction cup has adsorbed plastic bottles. It includes a manipulator shell 3 and a long bellows vacuum suction cup 4. The control element is integrated in the manipulator shell 3, which is easy to install. All pneumatic components, vacuum components and control circuits in the pneumatic circuit are integrated in the manipulator, and the electromagnetic reversing valve in the pneumatic circuit is controlled by a single-chip microcomputer.

[0040] The manipulator shell 3 is provided with a manipulator support 9, the bottom of the manipulator support 9 is connected to the long bellows suction cup 4 through the PMF board interface 7, the manipulator support 9 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com