Powdered scrap removing device for plate cutting

A technology for removing device and dust, applied in bark area/debris/dust/waste removal, wood processing equipment, stone processing equipment, etc. Reduce the effect of bristle deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

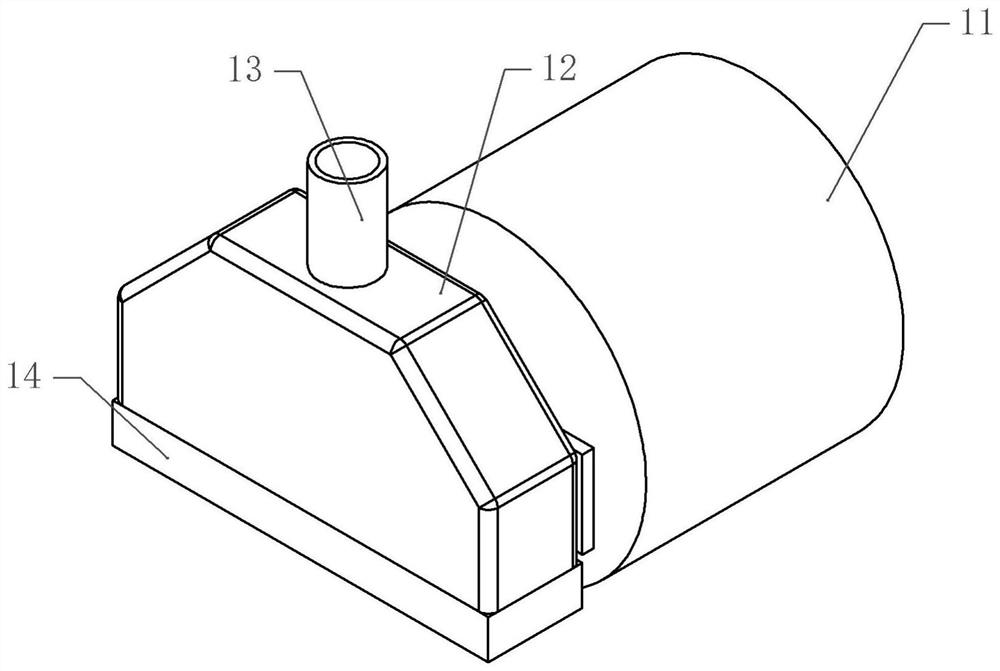

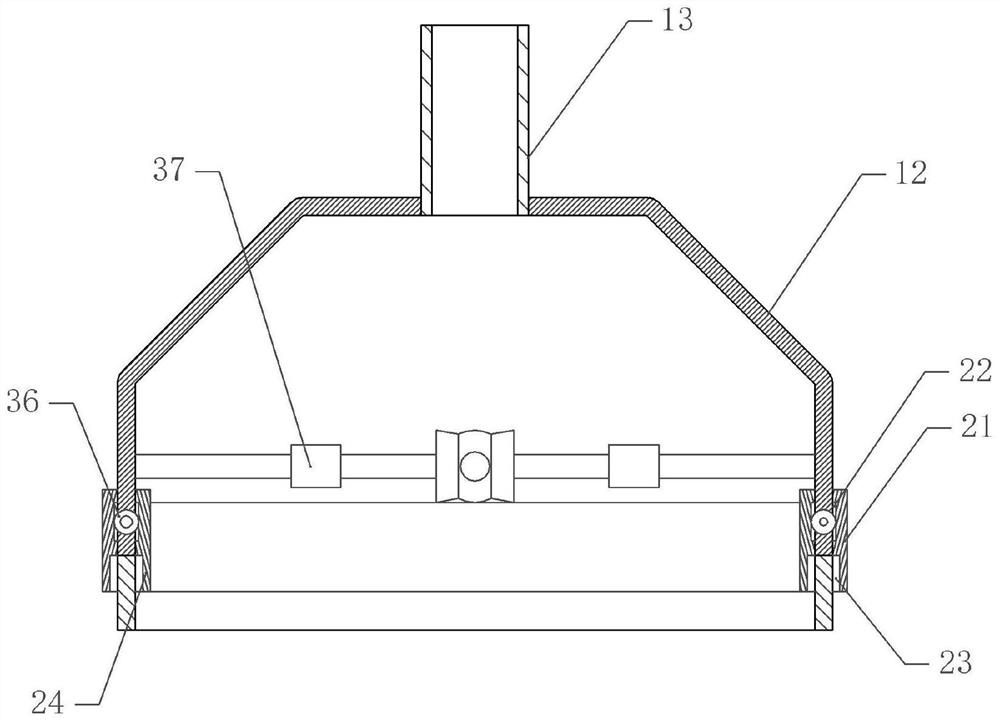

[0032] Basic as attached figure 1 , attached figure 2 , attached image 3 And attached Figure 4 As shown, a dust removal device for plate cutting includes a cover body 12 installed on the cutting machine, the upper part of the cover body 12 is trapezoidal, the lower part of the cover body 12 is rectangular, and the upper part of the cover body 12 is connected with a gas pipe 13 , the air pipe 13 communicates with a negative pressure machine, and the lower part of the cover body 12 is fixedly connected with a brush 14 .

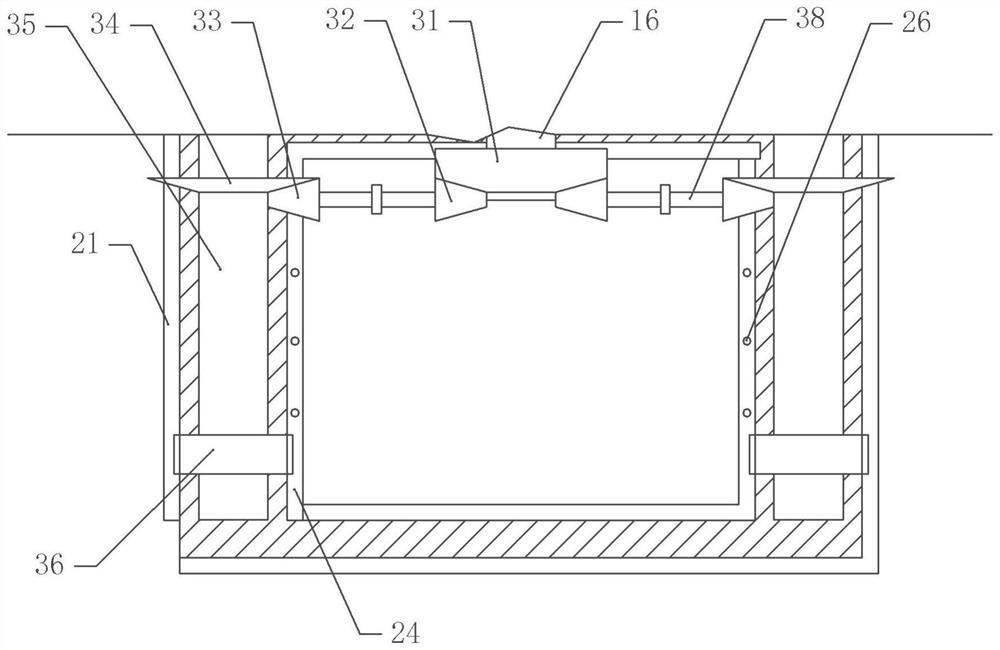

[0033] In this embodiment, both sides of the cover body 12 are provided with a cleaning mechanism. The cleaning mechanism includes a rotating shaft 35 that is rotatably connected to the cover body 12. One end of the rotating shaft 35 is fixedly connected with a half gear 36 (incomplete gear) with a coaxial bolt. Both sides of the gear 36 are provided with L-shaped cleaning plates, which are vertically slidably connected to the cover body 12, wherein one c...

Embodiment 2

[0043] The difference between embodiment two and embodiment one is that, as attached Figure 5 As shown, the connecting portion 37 is hollow, and the connecting portion 37 is provided with a cam 373 coaxially fixedly connected with the connecting shaft 38, and the upper part of the connecting portion 37 is provided with a push shaft 372 vertically slidingly connected with the cover body 12. The push shaft 372 Against the cam 373, an L-shaped scraper 371 is vertically slidably connected to the top of the push shaft 372. The horizontal section of the scraper 371 is offset against the push shaft 372, and the vertical section of the scraper 371 extends into the air pipe 13 and is in contact with the air pipe 13. Trachea 13 is close together.

[0044] The specific implementation process is as follows:

[0045] Since the dust will partially adhere to the air pipe 13, the excessive accumulation of powder will cause the diameter of the air pipe 13 to decrease. Therefore, in this embo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com