Multi-fold spherical silver powder and preparation method and application thereof

A silver powder and spherical technology, used in metal processing equipment, metal/alloy conductors, electrical components, etc., can solve the problems of small specific surface area, poor silver powder adsorption capacity, large energy consumption, etc., to increase specific surface area and increase adsorption capacity. , the effect of expanding the scope of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The method for preparing high-performance silver powder preparation of the present embodiment, concrete implementation steps are as follows:

[0035] (1) Preparation of reducing agent solution A: First, add 1L of deionized water into the container, add vitamin C powder under constant stirring, and prepare a vitamin C solution with a molar concentration of 0.5 mol / L to obtain silver-containing solution A;

[0036] (2) Preparation of silver-containing solution B: Add 500mL of deionized water to the reactor, add sodium citrate powder under continuous stirring, stir quickly until the powder is completely dissolved, and prepare a sodium citrate solution with a molar concentration of 0.2-0.6mol / L , then add 500 mL of silver nitrate solution with a molar concentration of 0.5-1.0 mol / L to the sodium citrate solution at a rate of 20-40 mL / min, and configure it into silver-containing solution B after the addition is complete;

[0037] (3) Transfer the silver-containing solution B...

Embodiment 2

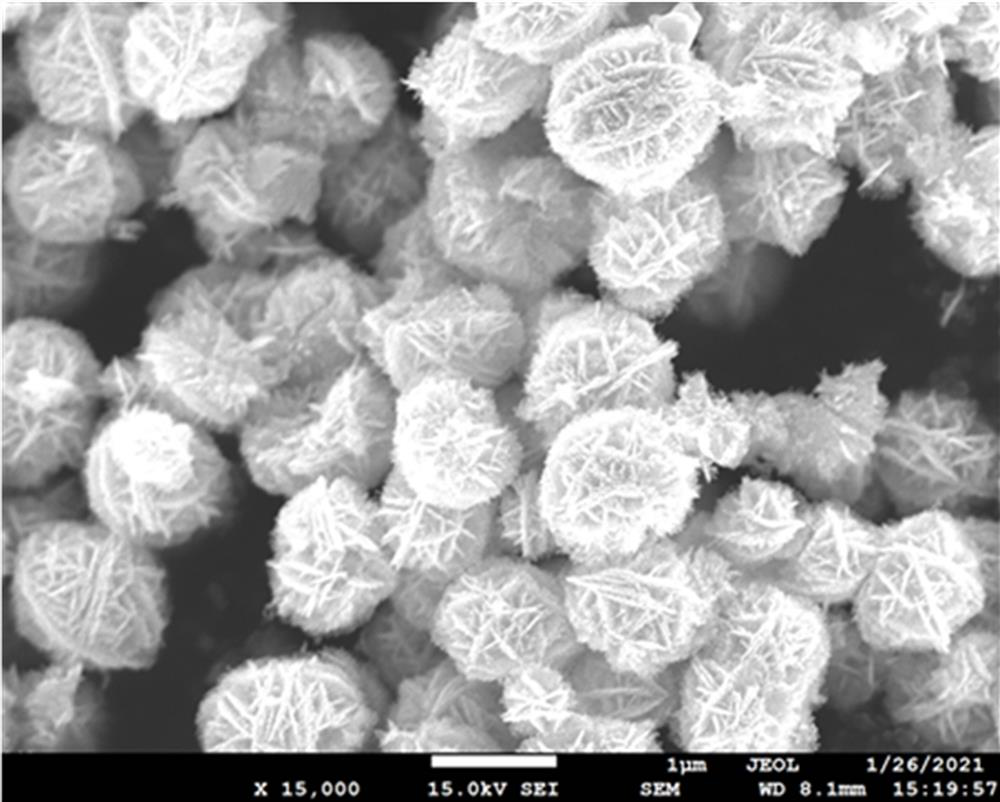

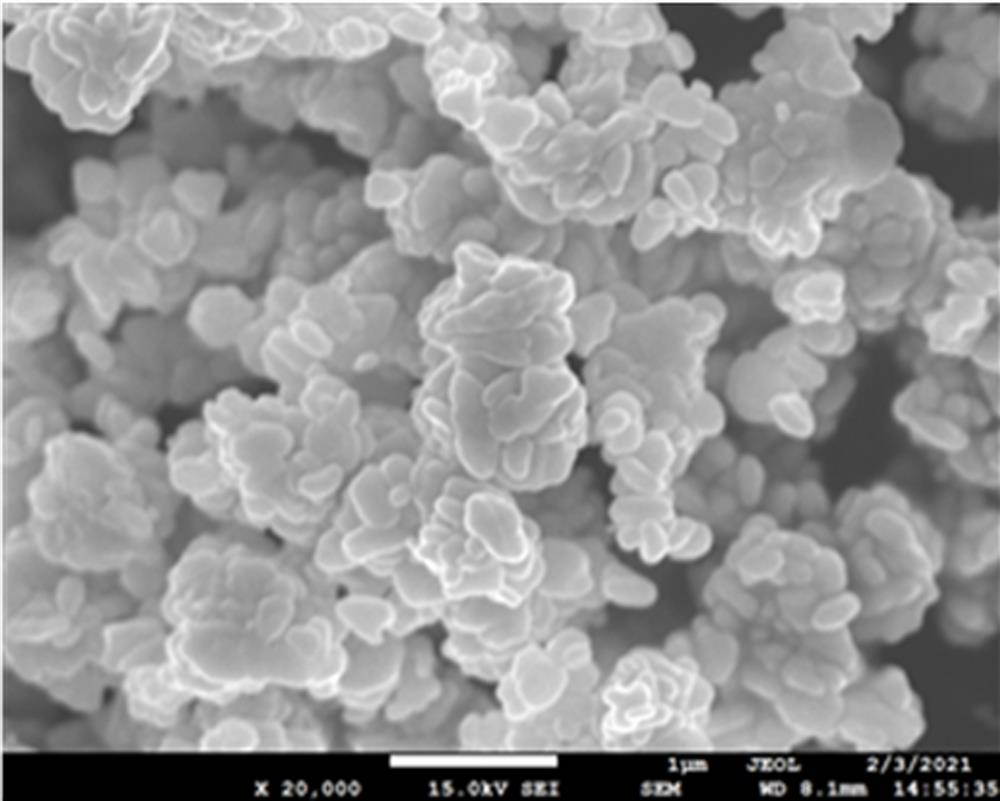

[0043] In order to verify the influence of reducing agent on the formation of spherical elemental silver in the preparation of silver powder in this embodiment, in the preparation process of silver powder, under the same conditions, D-ascorbic acid is used as reducing agent to prepare silver powder, such as figure 2 Shown, with D-sodium ascorbate as reducing agent, the silver powder that prepares, as image 3 shown.

[0044] according to figure 2 It can be seen that the silver powder prepared by using D-ascorbic acid as a reducing agent changes the sheet structure of the silver powder and cannot form a spherical shape.

[0045] according to image 3 It can be seen that although the flake structure of the silver powder is retained, the structure cannot be uniformly transformed into a spherical shape.

[0046] In summary, it can be seen from the above experiments that vitamin C was chosen as the reducing agent because vitamin C can reduce silver ions into spherical elementa...

Embodiment 3

[0048] In this example, in order to verify the effect of the amount of reducing agent vitamin C on the formation of spherical elemental silver, in the preparation process of silver powder, with other conditions unchanged, the molar concentration is 0.28 mol / L (molar concentration is less than 0.4 mol / L) Vitamin C solution, the prepared silver powder, such as Figure 4As shown, configure a vitamin C solution with a molar concentration of 0.17 mol / L (molar concentration less than 0.2 mol / L), and prepare silver powder, such as Figure 5 shown.

[0049] according to Figure 4 , Figure 5 It can be seen that when the amount of vitamin C is insufficient (less than 0.4mol), the morphology of the obtained silver powder under the scanning electron microscope, we can see that there is a sheet-like morphology, but it cannot be gathered into spherical particles.

[0050] according to Figure 6 It can be seen that when the amount of vitamin C is excessive (greater than 0.9mol), the mor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com