Silicon composition materials for use as battery anodes

A silicon composite material and battery technology, applied in the direction of battery electrodes, positive electrodes, negative electrodes, etc., can solve problems such as anode silicon detachment, achieve the effects of reducing capacity decay, increasing storage capacity, and promoting industrial production levels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

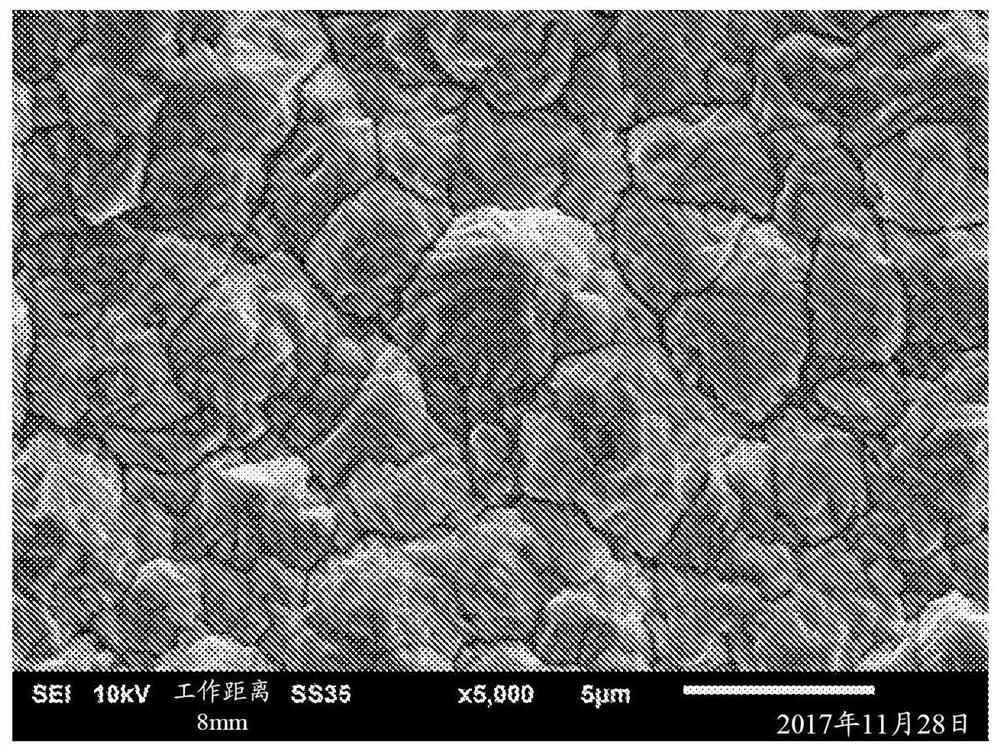

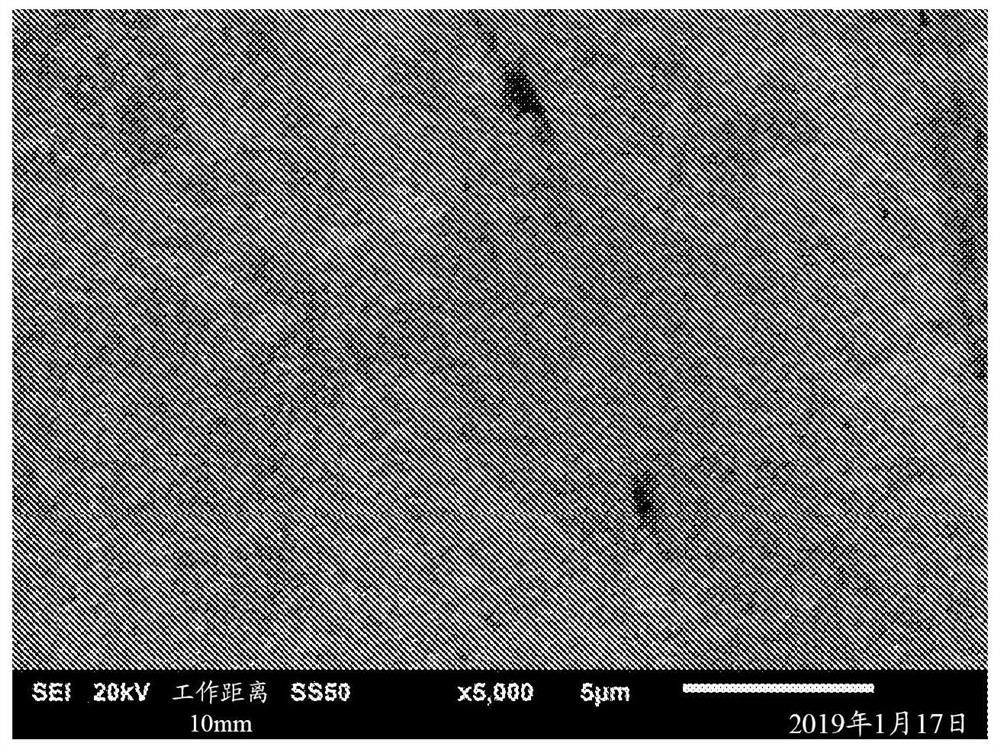

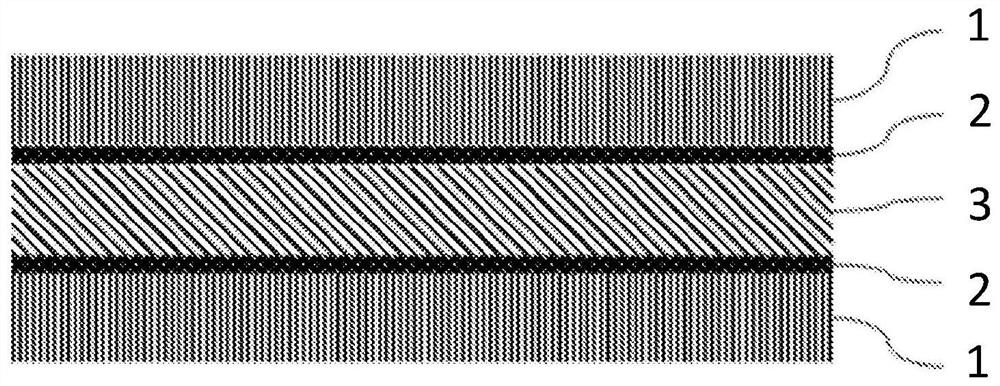

[0087] Copper foils giving good adhesion were prepared with an electrodeposition process which also included electrochemical deposition of a thin ZnO layer ( Figure 10 foil in 1). Next to it is also prepared by electrodeposition with deposited Cr 2 o 3 Coated copper foil ( Figure 10 Foil 2) in , and prepared by sputtering in thin Cr deposited by electrodeposition 2 o 3 Copper foil with Al-doped ZnO coating deposited on top of the layer ( Figure 10 Foil in 3). The elemental composition of the copper foil surface was measured using X-ray photoelectron spectroscopy. The results of the measurements given in Table 1 show that the surface of the copper foil is covered with a layer of metal oxides, namely ZnO, Cr 2 o 3 Or Al-doped ZnO.

[0088] Table 1. Elemental composition of the surface of the as-prepared anode measured by X-ray photoelectron spectroscopy.

[0089] element Cu Al Zn Cr C O P S Cl N peak 2p 2s 2p 2p 1s 1s 2s 2p 2p 1s...

Embodiment 2

[0093] The cycle stability of electrodes produced with copper foils comprising a zinc oxide adhesive layer was compared with copper foils comprising a coating made of chromate and foils without an adhesive layer. All foils are 8-10 microns thick. Lithium metal was used as the counter electrode, which in this example enabled the silicon-containing copper foil to act as the cathode rather than the anode. Since these experiments were used for comparative tests and stability tests, the results can be extrapolated to electrode layers comprising silicon as anodes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap