Wear-resistant and aging-resistant decorative material and preparation method thereof

A decorative material and anti-aging technology, applied in the field of decorative materials, can solve the problems of poor flame retardancy and performance stability, mechanical properties, wear resistance and aging resistance that need to be further improved, and achieve flame retardancy and mechanical properties Good performance, good comprehensive performance and performance stability, good durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

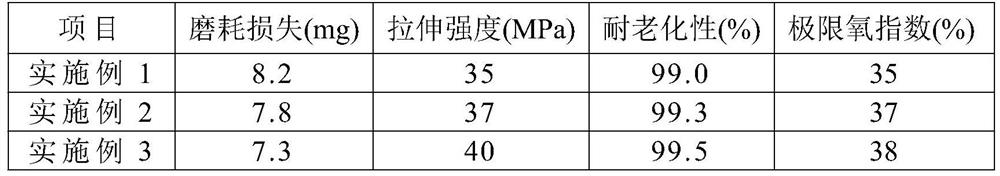

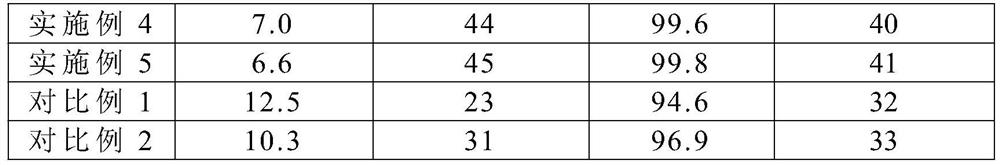

Examples

Embodiment 1

[0025] A wear-resistant and aging-resistant decorative material is characterized in that it includes a release film layer, a pressure-sensitive adhesive layer and a functional film layer from top to bottom; the functional film layer is made of the following components in parts by weight: Composition: 50 parts of hyperbranched polypropylene, 4-vinyl-2,8-bis(trifluoromethyl)quinoline / N-vinylcarbazole / 1,3-bis(oxiranylmethyl)- 20 parts of 5-(2-propenyl)-1,3,5-triazine-2,4,6(1H,3H,5H)-trione / vinyltrimethoxysilane copolymer, poly-4-methyl 2 parts of pentene, 3 parts of 2,4,6-trivinylboroxine, 8 parts of anti-wear additive, and 0.8 part of initiator.

[0026] The release film layer is made of a release film, and the release film is a PC release film; the release film is coated with a low-silicon release agent.

[0027] The pressure-sensitive adhesive layer is made of pressure-sensitive adhesive, and the pressure-sensitive adhesive is German Henkel acrylic pressure-sensitive adhesive...

Embodiment 2

[0032] A wear-resistant and aging-resistant decorative material is characterized in that it includes a release film layer, a pressure-sensitive adhesive layer and a functional film layer from top to bottom; the functional film layer is made of the following components in parts by weight: Composition: 53 parts of hyperbranched polypropylene, 4-vinyl-2,8-bis(trifluoromethyl)quinoline / N-vinylcarbazole / 1,3-bis(oxiranylmethyl)- 22 parts of 5-(2-propenyl)-1,3,5-triazine-2,4,6(1H,3H,5H)-trione / vinyltrimethoxysilane copolymer, poly-4-methyl 2.5 parts of pentene, 3.5 parts of 2,4,6-trivinylboroxine, 9 parts of anti-wear additive, and 0.9 part of initiator.

[0033] The release film layer is made of a release film, and the release film is a PE release film; the release film is coated with a low-silicon release agent; the pressure-sensitive adhesive layer is made of a pressure-sensitive adhesive, The pressure-sensitive adhesive is KL-6600 silicone pressure-sensitive adhesive.

[0034] ...

Embodiment 3

[0038] A wear-resistant and aging-resistant decorative material is characterized in that it includes a release film layer, a pressure-sensitive adhesive layer and a functional film layer from top to bottom; the functional film layer is made of the following components in parts by weight: Composition: 55 parts of hyperbranched polypropylene, 4-vinyl-2,8-bis(trifluoromethyl)quinoline / N-vinylcarbazole / 1,3-bis(oxiranylmethyl)- 25 parts of 5-(2-propenyl)-1,3,5-triazine-2,4,6(1H,3H,5H)-trione / vinyltrimethoxysilane copolymer, poly-4-methyl 3 parts of pentene, 4 parts of 2,4,6-trivinylboroxine, 10 parts of anti-wear additive, and 1 part of initiator.

[0039] The release film layer is made of a release film, the release film is a PET release film; the release film is coated with a low-silicon release agent; the pressure-sensitive adhesive layer is made of a pressure-sensitive adhesive, The pressure-sensitive adhesive is rubber-type pressure-sensitive adhesive glue HX6012.

[0040] T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com