Biofilm filler modification method suitable for natural water body and components

A technology for natural water bodies and modified components, applied in sustainable biological treatment, chemical instruments and methods, biological water/sewage treatment, etc., can solve the problems of discounted application effects, high prices of new materials, and not being widely used. Achieve the effect of easy to obtain raw materials and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] (1) Soak the ordinary biofiller of the PET material in a sodium hydroxide solution of 90 ° C, soaking time is 45 minutes;

[0037] (2) The filler ends the end of the (1) step is soaked in 1% polyvinyl alcohol (alcohol solution 99%, the degree of polymerization 1700) and 0.001% ethylenedialdehyde solution, soaking for 5 minutes;

[0038] (3) The filler was dried at 120 ° C for 20 minutes to obtain a modified biofiller.

[0039] Note: The method of the present invention relates to a polyester fiber surface treatment technique and a polyvinyl alcohol polycondensation technique. In the present invention, the surface treatment technique of the present invention produces uneven elimination of unevenness (polyester) fiber surface, increasing the adhesion of the surface of the filler. Ability; polyvinyl alcohol polycondensation techniques can condense the long chain PVA portion to form a varicon having strong mechanical properties, but it has water resistance, and thus the core of ...

Embodiment 2

[0044] (1) Soak the ordinary biofiller of the PET material in a hydroxide solution of 10 g / L of 75 ° C, soaking time is 30 minutes;

[0045] (2) Soak the filler in 5% polyvinyl alcohol (99%, polymerization 1700) and 0.002% ethylenedical solution, soaking for 3 minutes;

[0046] (3) The filler was then dried at 105 ° C for 15 minutes to obtain a modified biofiller.

[0047] Description of Example 1.

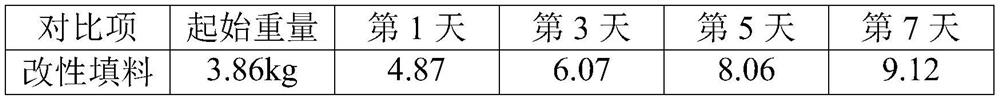

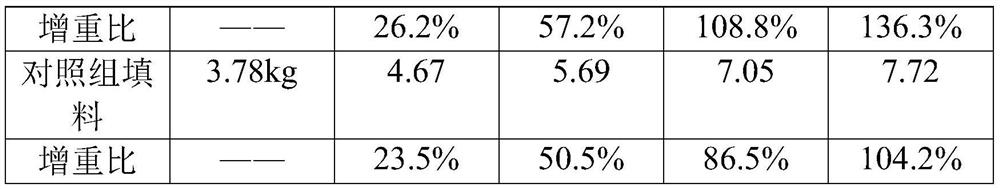

[0048] The modified biofilm with the control group (unremnive treatment) was placed in a certain river channel (the same, specifically in the middle of the zone), recording the hanging film, the record weight is shown in Table 2 below:

[0049] Example 2 Comparison before and after filler modification

[0050]

[0051]

PUM

| Property | Measurement | Unit |

|---|---|---|

| alcoholysis degree | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com